| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

Well the test run was dissapointing. I couldn't do the same lines I used to be able to stock. Lines like this one http://www.youtube.com/watch?v=fNbNwXaSqnU Even getting onto the first rock was hard and climbing up the second step was hopeless. So I cleaned up the stock shocks, put the shafts back in made sure the orings were inside the caps and superglued them on. One other mod that has made a huge difference is drilling a small hole into the rim to let air escape. The tires fold much better and with the stock foams there is still plenty of sidewall support. |

| |  |

| Sponsored Links | |

| | #22 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

So after some chat on the board (see this link Traxxas big bore problem, breakover is no good) I thought I'd see if I could keep the truck low and have lots of down travel...the theory being that my axle would drop and pull me over the obstacle. I put my stock shock bodies back on with the big bore springs to keep it lower. This was the result, a bit better than straight up big bore shocks but still couldn't to this line no matter how hard I tried. If you're into a rediculous amount of uncontrolable flex/droop this is your set up. I find it super irritating and completely unrealistic. I had to add a bunch of spring spacers too to make it driveable. Withought them the body roll was a joke. You can see how bad it is in the first few seconds of the video: http://www.youtube.com/watch?v=EN8WuEkmcEY For comparison this is the same obstacle with a completely stock setup with the battery mounted in the stock location and no added weight to the axles: http://www.youtube.com/watch?v=fNbNwXaSqnU This is how it looked at ride hight, stock shock bodies, big bore springs (without two thick spring spacers):  And full flex:  On the rocks:   So the verdict, axial did a pretty good job out of the box. I'm putting back the stock springs and shocks. The next mods will be wheelspacers to make up for the height and high clearance links. And it's too late since my caps are glued on but a thinner shock oil would work a lot better I think. Joe Last edited by miller; 10-13-2007 at 06:10 PM. |

| |  |

| | #23 |

| Rock Crawler Join Date: Apr 2007 Location: portland

Posts: 584

|

wow. that did suck. Well I have to thank you for doing this test of the big bores. I have a set that I was ready to put in my ax10 but I won't be doing that now. Im just gonna limit my stock ones. Lower the truck a bit. thanks again man.

|

| |  |

| | #24 |

| I wanna be Dave Join Date: Jan 2004 Location: Detroit

Posts: 3,583

|

Having a huge battery pack on the rear axle is hurting you...thats weight that gravity gets free reign on to pull down while you are trying to go up... I say re-configure the pack or strap it to the front axle and get rid of the lead weights. Worth a shot. |

| |  |

| | #25 |

| Rock Crawler Join Date: Mar 2007 Location: Colorado

Posts: 635

|

looks awesome and great mods... i heard you wanted to make a replica of your 1:1 using hilux body? if i were you i would look at the 2.2 wheel and tire selection because the Nylint tires that you pointed out would be way to big and 1,18 nylint tires arent as good as 2.2 tires. IMEX makes awesome realistic tires..... a yota tuber would be awesome. Last edited by balang_479; 10-10-2007 at 06:56 AM. |

| |  |

| | #26 | |||

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

| Quote:

Quote:

If I took the weight off the back I might be able to drag my self up....but that takes away some of my low COG although I do gain some by lowering it so they cancle eachother out....but then I'm not as stable going down hill so I don't gain anything from taking the weight off the back. Everything I have on this rc and don't have will be for a reason that is tested...just like scrapping the big bores. Quote:

I bought the rockworks toyota body but I don't like it. It's super floppy compared to the betty body so I'll be sticking with the betty untill someone comes out with a good toyota body. I think the axials kinds look a tiny bit like my IROKs so those will be staying. Joe Yes I know the IROKS are on backwards, in the pic they were thrown on to check for clearance on everything.   Last edited by miller; 10-10-2007 at 11:27 AM. | |||

| |  |

| | #27 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

Did some night crawlin tonight. Stock shocks are back in and went to go see if I could do that line...no problem        |

| |  |

| | #28 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

Bent my stock links to match the drive shaft clearance...this should make it a ton more capable on the terrain I have. Before:  After:   and should be the same belly height as stock.. 3.5 inches?  And gonna order up some wheel spacers this week  |

| |  |

| | #29 |

| Quarry Creeper Join Date: Sep 2007 Location: Steubenville

Posts: 249

|

Some of you guys booty fab your brand new rigs so bad? Why? Zip ties? Zip ties are to hold wires in place, and tie things out of the way. The battery on the rear axle... I tried it. It works ok, but not in competitions. It makes your rear tires get stuck in holes, and maked the truck wheelie climbing extreme angles. Its NOT GOOD for the super technical stuff escpecially in Competitions. It makes the rear ends way too heavy! YOu want two 3 cell saddle packs on the front axle. 6 cells, divided in 3 and 3 that mount up front on each side of the servo. This is the desireable set up. Holmes Hobbies has these ready to plug in. I would have bought these in the first place if I knew about them... but I spent $50 on two humongous 3000 sub C huge batteries. The front axle saddle is the key. If you really have your heart set on putting the battery back on the rear axle... THE PROPER WAY TO DO IT is to use the big battery tray from on top... take it off the top and put it across the rear axle. YOU need to drill 3 holes, and countersink the screw heads. remove the rear small servo tray... use the 3 holes in the rear sevo tray as a template to drill 3 new holes in the big battery tray. This is IMPORTANT so the 3 holes line up perfectly with the axle mount holes. Counter sink the heads screws in the big battery tray so they don't stick up. Use a bigger bit, lightly just enough to countersink the heads. Mount the battery across the rear axle, with the big battery tray CENTERED, screwed down, mounted with the 3 stock holes on the axle housing, with the 3 new holes drilled. Easy stuff. Use a 3M strip of VELCRO TAPE that comes in a roll. Cut a strip on the battery tray, and a strip on the battery. Then you don't stupid zip ties everywhere, and it looks nice. And the battery won't move at all. Be careful not to LIMIT DOWNWARD DROOP with the battery wires. It works, just not ideal. You want the weight on the front axle. For play, it would be fine in the back. Last edited by Barillms; 10-30-2007 at 02:41 AM. |

| |  |

| | #30 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

I wasn't aware that the individual cells of batteries on the front axle looked that much better than one pack on the rear axle Everything that is on it is there for a reason. It's built for my crawling areas and everything on it makes it work better. If it worked better with just the battery on the front axle then that's how it would be set up...but it doesn't. I fall ass over end on steep decents with it set up like that. And hopefully nobody pisses in your cornflakes again tomorrow morning. I see you edited it to sound a bit more friendly...so take my rebuttal with a grain of salt ;) Last edited by miller; 10-30-2007 at 03:01 AM. |

| |  |

| | #31 |

| Pebble Pounder Join Date: Jul 2007 Location: Okinawa, JP

Posts: 166

|

whats wrong with zip ties??? it's the 1/10 equivalent to duct tape

|

| |  |

| | #32 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

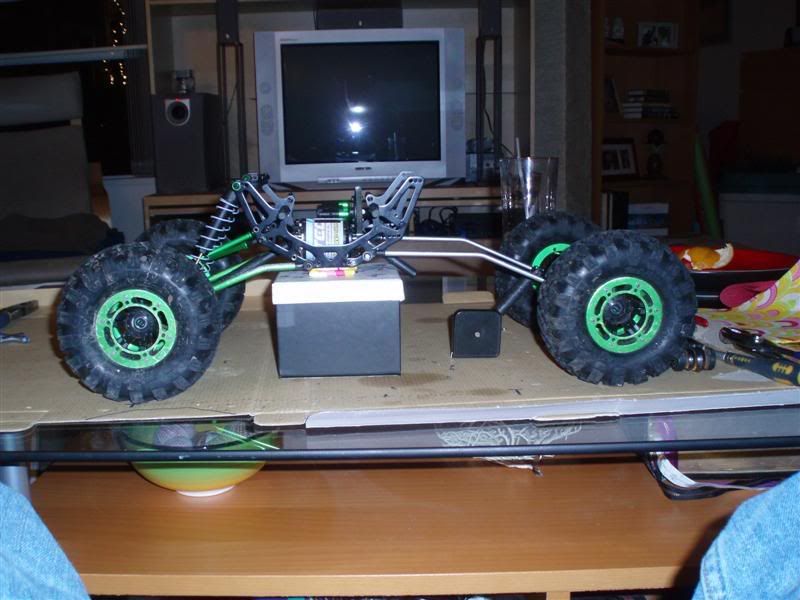

Gonna be getting some rockstompers so I decided to stretch my wheelbase out to 15" so the new meats fit better and am playing with weight distribution. 8cell saddle pack will be going on the front axle...I'm hoping that the extra wheelbase will keep downhills manageable which was the point of the battery on the rear axle originally. Started by drilling new holes.  Actually decided to use the stock front setup and just stretch the rear and extra 3".  Wont look as long when the bigger tires go on. Still need to do the upper links but am waiting on rcp's wishbone eliminator mount plate..which will also be going on the front.  Waiting for Christmas to come so I can finish it |

| |  |

| | #33 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

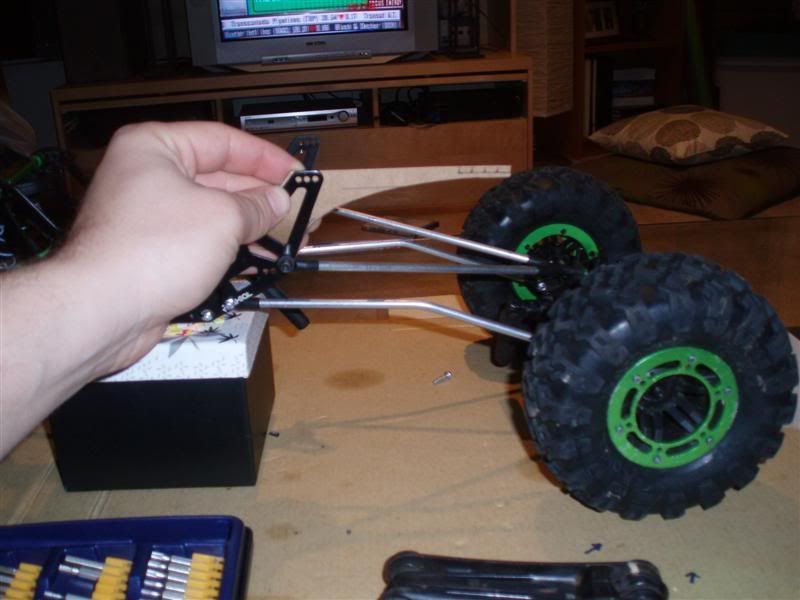

Well I couldnt wait so finished my uppers using the stock wishbone set up...my links should be fine to use with the 4link conversion since it's meant for the stock set up. I also tried to get a bit my triangulation on my lowers to fight axle steer. What would be ideal is to be able to get the lowers fully triangulated but it's hard to get the space...eventually that will be the next step.  My links hit but when my 4link plate comes in I'll be able to bring my upper links more inboard and they shouldn't have any contact.     And then made my template for my shock mounts. These will be 1/8 aluminum plate.  Just need to do some reading to find a driveshaft that will work...or get another scorpion on and make two into one that's long enough. Last edited by miller; 12-03-2007 at 11:07 PM. |

| |  |

|

| |