| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| Quarry Creeper Join Date: Nov 2004 Location: Ground Hog Plains

Posts: 272

|

Im loving this build thread. Nice work. I picked up a 1991 suburban that I want to make my hauler.

|

| |  |

| Sponsored Links | |

| | #22 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Thanks man. This is, although very tiring, and hard on my body, still a very fun project. More progress. Got alot done tonight. Even though it doesnt seem like much, with how long it has taken me on other parts to clean stuff, this is damn good progress. Pulled the truck out in the gravel with the tractor, and lifted it up with a cherry picker to be able to get better aim underneath. Spent 3 hours pressure washing until my hands went numb lol. It was like 28 degrees out, and the water was freezing in like 10 mins. Looks so much better. Missed a couple spots, but 99% of it is great. Going to pick up some rustoleum to paint the bare metal. Also got all the big parts cleaned too. Still a ways to go, but Im SOOOO close to dropping the motor in. More to come.  Spot light.  CLEAN! Before and after:    |

| |  |

| | #23 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

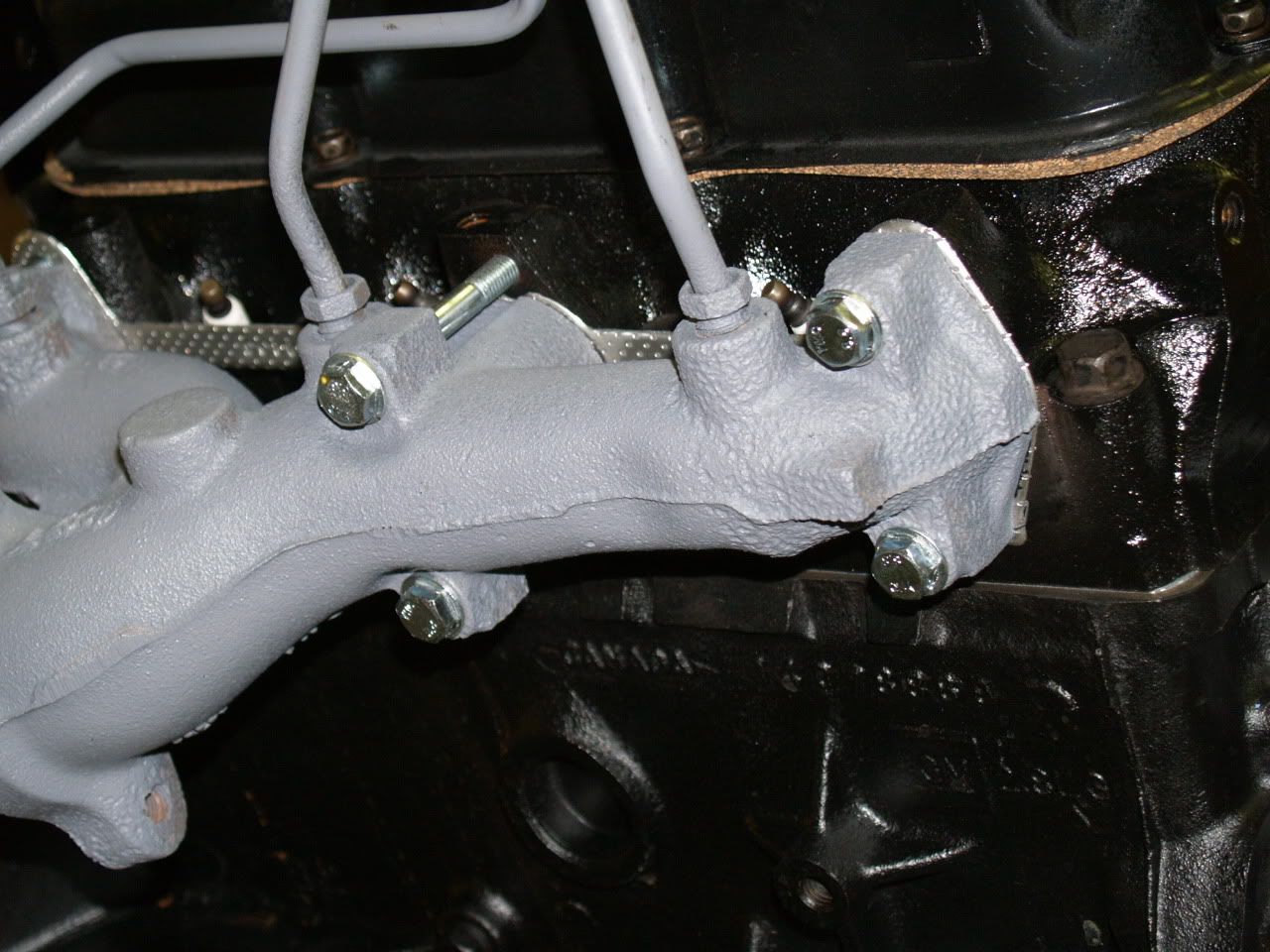

More done. Got to the next checkpoint. Last night wasnt so smooth. The adjustment of the valves were a little too confusing at the time, and without confirming my assumptions with my machinist buddy, I just said Eff it, and finished it today. Got the valved adjusted, and the rest of the stuff on the motor. Aside of popping it off the stand, installing the rear cam seal, and the Clutch/Flywheel, it is ready to drop in. I was a dumb, and bought 1 too little bolts for the exhaust. So I had to stick one of the old ones back in. Tomorrow when I go to napa, I will get another. This one will stay incase I forget. The seal kit I bought had no fuel pump seal either, so I had to redneck it, and just permatex the hell out of it. It should hold, and it is easy enough to access if it doesnt. Wish the motor matched a little better lol, but it is probably one of the cleanest, and nicest 2.8l Chevy motors this side of the Mississippi Also got the engine bay finished. Not perfect, but it is more rust prevention. So tomorrow night, I am going to install the cam seal, and the clutch/flywheel, then drop it in. Want it at least bolted to the tranny by the nights end, and hopefully half plumed in. Still need to clean a few more things, and rebuild the carb, but all in all, 75% of the work is done. More to come...   The dipstick broke. My welder isnt that great, so it had to be soldered. Ugly, but functional. Just so happens I know this ugly ass dude, that makes some kick ass batteries that soldered it up for me  You wish your exhaust looked this nice  A few other little details. Took all the weathering off all the bare metal parts, and high temp, clear coated em so they would last longer.    |

| |  |

| | #24 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Is it in yet? I can finally say yes without being embarrassed!  There she sits. As usual, everything has fought me. Had to make a tool, to get to 1 nut, that GM was fawking awesome in putting inside the frame rail, and giving such a small ass hole to get to it. Thanks GM  I was hoping to have the motor plumbed in half way, but it shouldnt take that long. Have to hit up Napa in the morning to grab a couple more bolts. Pretty much everything is ready to be bolted on, and fluids put in. Also need to rebuild the carb, but that shouldnt take long More to come.  |

| |  |

| | #25 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Much disappointment So not only did it take twice as long as it should have to get it put back together today, BUT, to top it off, I couldnt even start it, because there is something wrong with the starter.  But hopefully I am hearing right, and the "ping" is the gear hitting the flywheel. Sounds like it. But I will have to wait until tomorrow so I can get under it and have someone try and start it to see. But hopefully I am hearing right, and the "ping" is the gear hitting the flywheel. Sounds like it. But I will have to wait until tomorrow so I can get under it and have someone try and start it to see.Had a hunch I would have issues with this, when I was spending over an hour to get the stupid son of a b!tch in. Had to put the cherry picker on the motor, pull the mounts, then lift it to get it in. That was all in an effort to not have to pull the manifold. But the exhaust doughnut wouldnt fit between the exhaust and the manifold, so I still had to pull it anyway What an effing day Some more icing on the cake was... When I grabbed the cherry picker to re-pull the motor to fit in the starter, it caught the leg of my folding table, and collapsed that side, making it a ramp, and everything slid across the floor. Then when I was putting on the last hose, I noticed my solder joint on the dip stick tube broke. So that will need fixin, un less it doesnt leak, then I will just say Effit, and leave it be I really love GM's 1984 engineers. They are my BFF now.  The tool I made last night for the front diff  One of the exhaust bolts was broken, and napa wanted like 8 bucks a piece for them. So I bought regular bolts, and then put a small tack weld to stop it in the same place as the stock shoulder  Couldnt find the heat shield for the wires going to the starter, so I had to make mine  My ghetto fix on the alt bracket. Just clears the belt.  It's ready to fire once I figure out the f#cking starter  |

| |  |

| | #26 |

| Rock Crawler  Join Date: Jun 2009 Location: summertown

Posts: 512

|

take a piece of 1/8" rod and place between the flywheel gear and the armeteur of the starter, that will tell you if it's shimmed right  as far as having someone help you start the truck, unplug the hot wire on the coil and make a 10guage jumper wire with alligator clips.. jump it from the hot post on the starter to the "S" terminal on the starter  or just use a screwdriver.... or just use a screwdriver....Looks great, Congrats on the progress |

| |  |

| | #27 | |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| Quote:

Thats what I intended on doing and did. Made one for cheap. Worked like a charm  It's alive! Upon removing the starter, I took it apart, and there was a chunk of something in it. It looked like it was holding the thing up from starting. So I cleaned out the starter, and removed the chunk. Then I re-installed it, and preyed to the gods I don't believe in, and it turned over!! The piece that was holding up the starter  Turned tit over for about 30 secs to prime the oil pump and fuel pump, then got in it, and it started. Ran like crap, so I put the timing light on it, and it was at like 30 degrees retarded. Cranked the distributor to 8-9 advances, and it purred like a kitten on catnip. Once I turned it off, checked the water, and topped it off. So far so good The valves made a little noise at first, but then quieted up soon after. So I think I got lucky The exhaust was billowing out steam like no ones business, and I freaked out, but realized that the exhaust probably had water in it from pressure washing. It cleared up after a minute. The paint was burning a little too lol. So the cab is currently hot boxed.  Had to get a switch, and make a starter switch to manually crank the starter for testing. Napa wants like 20 bucks for something like this, and I made this for 8.29. Works like a champ Crappy pic  I am still a little pissed at GM and their engineering though. In order to take the starter out, I had to remove the cross member. There were 6 bolts. And of course there was a hole in the frame to catch the nuts. So it will be fun to put it back in without losing them in the frame. Not to mention, 1 of the nuts, had fuel or brake lines or something in the way, so I had to wedge the sh!t out of the ratchet to get it in. So tomorrow after work, I am going to rebuild the carb, re-install the cross member, and maybe the skid plates, re-install all the crap around the shifters, and take her out for a spin. With any luck, it will run well. More to come **This is just the beginning of this thread. Coming after this will be some cool interior work, roof rack, small lift, and...? Then SAS someday with any luck.** | |

| |  |

| | #28 |

| I'm a stupid C U N T! Join Date: Jun 2005 Location: In the Garage!

Posts: 4,307

|

Good to hear it fired up and runs well  Staying tuned for further updates. You wan tto freshen up my 89 4.0l Jeep motor for me? Staying tuned for further updates. You wan tto freshen up my 89 4.0l Jeep motor for me? |

| |  |

| | #29 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| |

| |  |

| | #30 |

| Quarry Creeper Join Date: May 2010 Location: South Central AR

Posts: 199

|

Nice Thread. What are the tubes coming up from the exhaust manifold? I've never seen anything like that. My cousin had a S-10 with a 2.8 and I don't remember those tubes. Glad it's running for ya. |

| |  |

| | #31 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

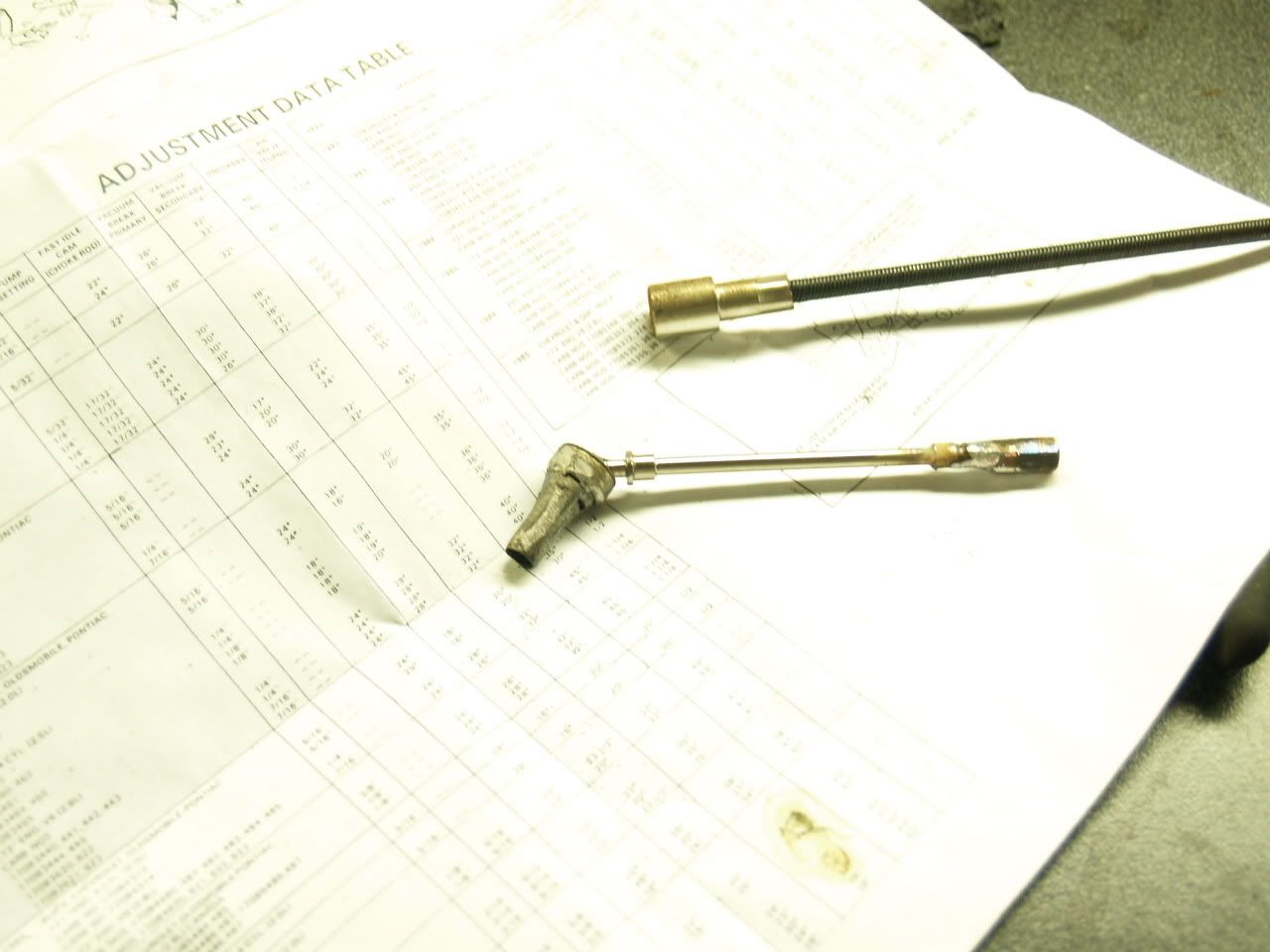

It's been a while since I updated this, so heres a little update She is back on her feet, and I have put about 1,000 miles on her with no problems as I can see. Have been tinkering with the carb, but lost the tool I made to adjust it, so I need to find it, or make another. The pics for the carb rebuild didn't turn out, so we will skip over that. It wasn't very exciting really. But it was pretty easy, once I tinkered with it some.  Here's the tools that I had to make or buy, just for this project  I made this fancy tool for the carb. My initial idea was to weld a piece of piano wire to the bit, and bend it in there, but that didn't work out too well. So I had a chewed up axial CVD that worked out great. Welded the bit to the end, after I cut out all the extra material, so it would fit. Then welded a bit head to the other end, so I could turn it with a driver. Worked out great.... until I lost it the other day when I needed it to do some more fine tuning  Fits well. 50 degrees babay!  More to come fairly soon. Since the last post, I have joined s10forum.com, and am reading alot about SASing these things. Actually probably going to settle for a heep HP30 front end, and a exploder 8.8 rear. Pretty in expensive. Going to start slowly gathering parts. Just got some donor interior parts for all my cargo area mods, so I may get started on that soon. And the paint will be getting touched out within the next couple weeks, so it should be all purdy! Stay tuned for some kick arse interior works... |

| |  |

| | #32 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| Those are the tubes for the smog pump. It pulls the un burned gases out of the exhaust, and puts it back into the combustion process.

|

| |  |

| | #33 | ||

| I wanna be Dave Join Date: Feb 2005 Location: Cleveland, OH

Posts: 8,009

| Quote:

Quote:

You didn't mention it, but did you replace the valve stem seals? It may or may not be a problem for ya, but I've seen some instances where replacing the stem seals makes the raings start leaking more. I guess the engine gets used to a steady diet of oil or something | ||

| |  |

| | #34 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

First off... I wanted to Thank the following people for their help during the motor project, and helping with the next phase Chad Hand(BURRLYTLT): For countless hours on the phone, answering general questions, General motor advise/guidance, parts, and help with manifold. Jim Hand(Mini Wheeler): For countless hours on the phone, answering general questions Tom Havel(Sourdojack): For countless hours on the phone, answering general questions Scott Van Ortwick, Stan Hackathorn, Mike Adenau: Tool usage, and general advise My boss, Mike Frederick: Letting me use the shop, and work truck. Now on to a little update. Got this cute little winch from a buddy for a song. It's only a 2500lb mile marker ATV winch, but I figure most people dont use one on budget builds, and it's better than nothing in snowy conditions, when I seem to need one  And this is going to be a slow project, but as deals present themselves, and money is available, I am going to start gathering for my SAS. Picked up this HP Dana 30 tonight in pieces for 50 bucks, locally. Wasn't really looking to buy anything this soon, but since anything of substance is at least a 45 min drive, it was local, and it has new ball joints, I couldn't pass it up. It has 3.07's. So it being apart, for 4.10 swap is no worries. More to come. After thinking/talking about it, I am probably going to to a linked setup, similar to the Rubicon express........  |

| |  |

|

| |