| | #1 |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

|

This is a Q for those who work with dimension printers... Will the dimension print material handle the stresses a crawler chassis has to support??? |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Jul 2011 Location: Lake City, Fl

Posts: 380

|

I'm by no means "in the field" or an expert on the subject, but I think they're more or less just for prototyping 3 dimensional objects, and I don't think the printed product is very structurally strong BUT depending on how complex the part is you're trying to make, you could probably print it, create a mold of it with plaster, and then melt some plastic or maybe even metal (if you can get enough metal hot enough), and try to cast the final product |

| |  |

| | #3 |

| Rock Crawler Join Date: May 2007 Location: Corona, CA

Posts: 581

|

Light testing would be ok if you use abs+ material. No way though if you plan to really work the chassis. I have used abs+ for some parts but they had some beef to them. The dimension parts work great for make sure parts fit and move propertly like knuckles and C hubs. Flat stuff like chassis it just make more sense to get it laser cut.

|

| |  |

| | #4 | |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

| Quote:

| |

| |  |

| | #5 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

It will easily prove out your suspension layout and any clearances you've built in. You MIGHT be able to get away with actually running it, but I don't as they're usually fairly brittle. Make it thicker than your production versions and you may be ok. |

| |  |

| | #6 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

We have a Dimension here at work. The parts are strong but I can't see it holding together for very long under the stress a crawler can put out. Of course this depends on your design and how hard you are on it during your testing. Is there a particular reason it has to be plastic other than the cost of machining? What is the final material going to be? |

| |  |

| | #7 |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

|

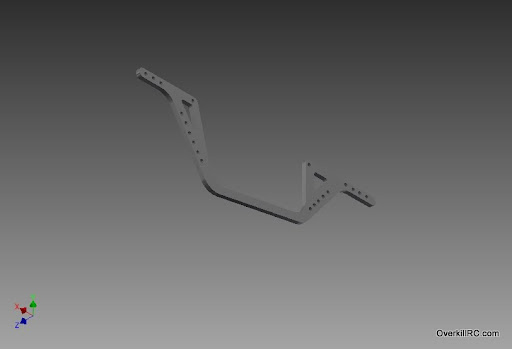

It'll be 1/8" delrin eventually, i'm working on a lcc replacment chassis. Its just for testing, i don't plan on being too hard on it (falling off a cliff, jumping, etc) Mostly just to test it till i have 20+ chassis cut out. There's other structural elements, just haven't modeled them yet, this is just a sketch   |

| |  |

| | #8 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

A print of that will not hold up at all. Having something like that cut really shouldn't cost more than $10 a chassis or less. |

| |  |

| | #9 | |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

| Quote:

It will have more support to keep it from folding in on itself if thats what your wondering/thinking... | |

| |  |

| | #10 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

That part won't last at all done up as a rapid prototype piece. Not if you're going to run it anyway.

|

| |  |

| | #11 |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

|

explain, where's the fault...where will it break? The above is no where near the complete chassis, just a sketch i drew up of what the profile will be, it will be getting more beef to it

|

| |  |

| | #12 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

There may not be a fault in the actual design, but a rapid prototype part is brittle. Like I said before, we use them to prove out suspension and link locations, NOT to actually run them. If nothing else, double up the thickness for your prototype if you still want to run it. Don't expect it to live though unless you add a bunch of bracing. Bracing that may not necessarily be needed if you were using the production material. |

| |  |

| | #13 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| |

| |  |

| | #14 |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

|

just wondering, if this material is so brittle...why can you make springs out of it?

|

| |  |

| | #15 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

Why ask for opinions, just have the chassis made and find out for yourself. You're not out much if it breaks.

|

| |  |

| | #16 | |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

| Quote:

Also because i don't want it to crumble within 5 minutes and kill hours worth of work Just trying to figure out if i can get afew non abusive hours out of it. | |

| |  |

| | #17 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

Since you're disagreed with everyone who has said you're likely to have issues, have at it. I'm sure it will be fine now. Also, if you're that worried about a $10 R&D investment for your business, you shouldn't be in business... |

| |  |

| | #18 | |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Quote:

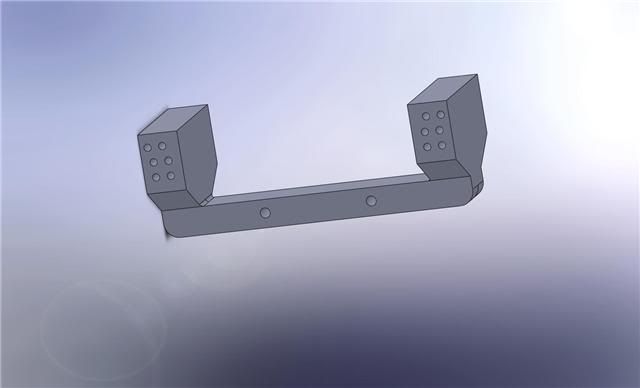

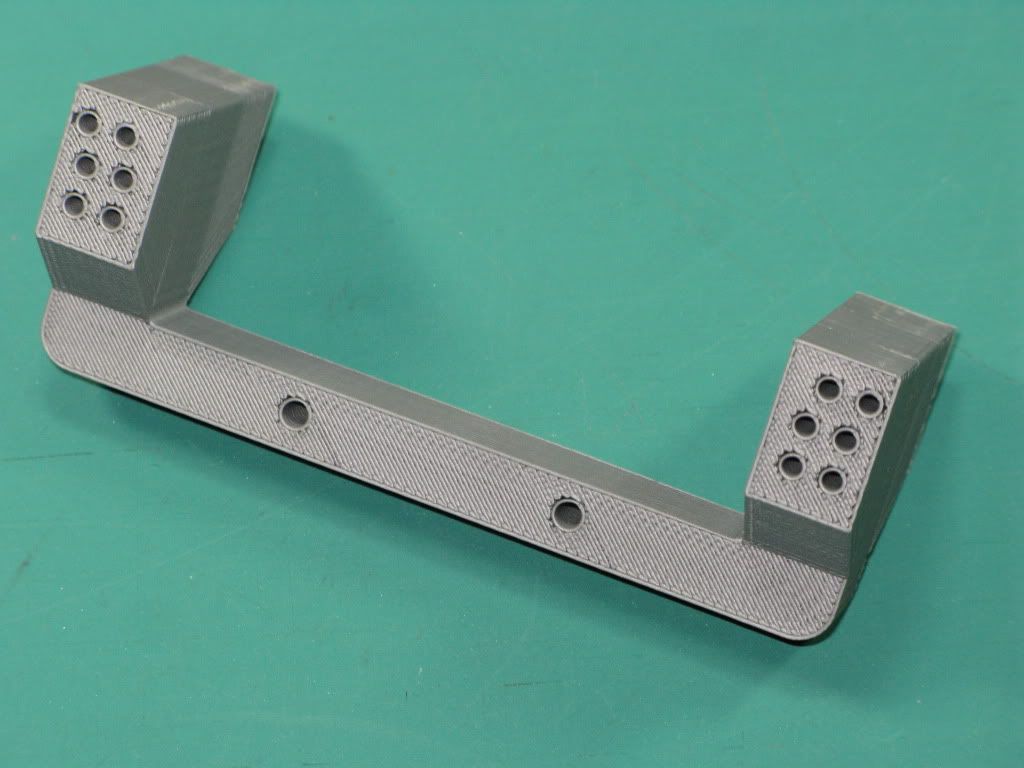

This looks like a very simple part to machine from 1/8" delrin. I don't know where you buy your delrin from but I have some laying around. If you really want to test this out with the material you intend to make it from, and if I have big enough pieces, I can make it for you. That way you can get some real information from your testing. | |

| |  |

| | #19 |

| I wanna be Dave Join Date: Aug 2007 Location: *

Posts: 2,274

|

I used a Stratasys Dimension printer for a chassis a couple of years ago. The material can be strengthened using thin CA and saturating the material. The piece I designed was thick enough that the forces it would be subjected to would unlikely break-it (I did carry a spare in case).   Looking at your planned design, I'd say the material will be subjected to forces that will make the structure fail. |

| |  |

| | #20 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

If you look closely at the construction of his part, you can see why the chassis would break apart. The Dimension extrudes lines of plastic, layer by layer to make the part. 1/8" is not very thick for these lines to get strength from. One thing I would do differently on Hartman's part though is print the part as a solid and drill the holes afterwards. I've done this with parts we make at work and the holes come out much better especially if they are intended to be tapped. |

| |  |

|

| |