| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

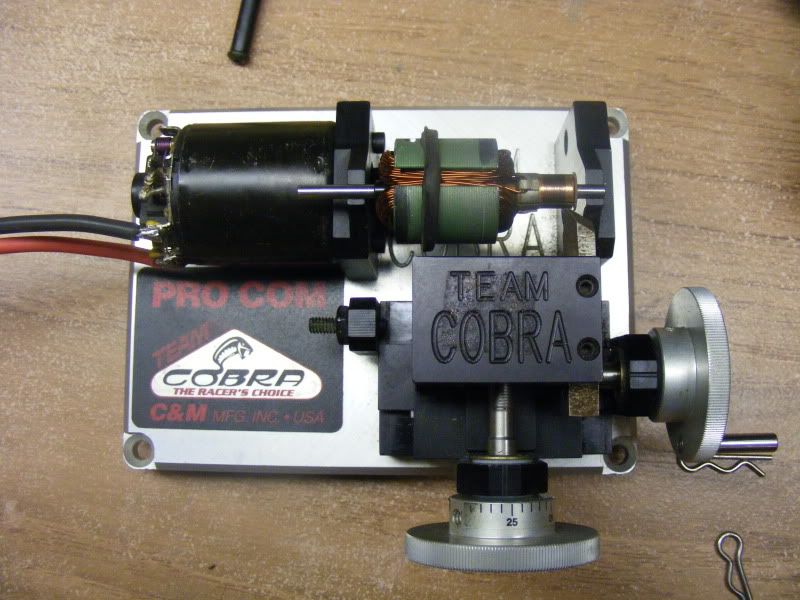

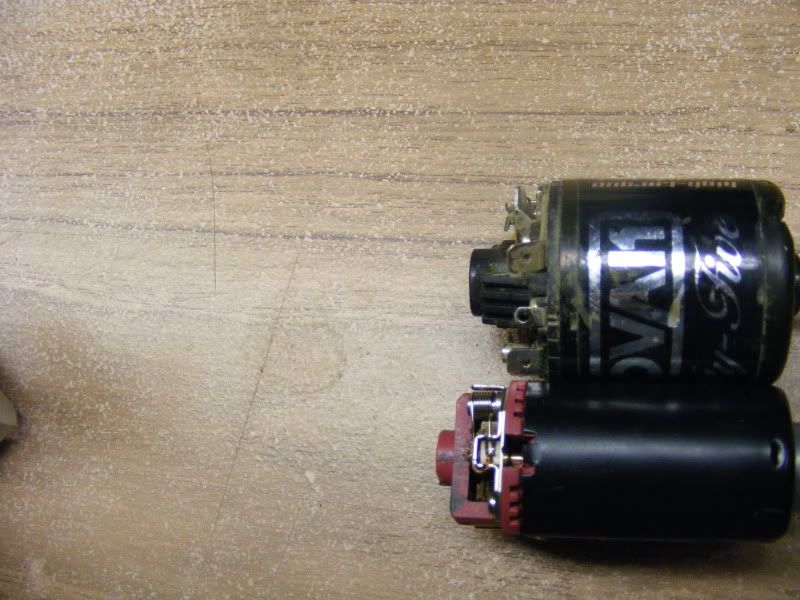

Since this was posted on my build thread, I figured that it wouldn't get seen as much by those that would like to know. So I copied and pasted to KIND OF share. It's a little top secret as to what they come from. And I am sure there are some people on here that know what the motors are for, but I would appreciate it if you would keep your lips sealed, until I confirm that this is even something that will work. Well I came home with this tonight. Wanted to start making some nice motors. So I will need this to start with.  And then I stumbled across this little bit of top secret motor goodness.... I have a suspicion that it will be the best of both worlds(Puller vs. 540 lathe). From my understanding, longer motors, naturally have more torque. And upon a little research, this looks to be about a 19t motor. So once I practice on some old burnt up Integys, and then I'll make a pair of these into 40t motors. This will make the 86 jeep style servo, fit with no problems........ More to come.  The comm out of the can. The shorter, larger diameter one, is the 540 lathe comm.   |

| |  |

| Sponsored Links | |

| | #2 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Torque is directly proportional to length in a positive 1:1 relation, but related to the square of the diameter. In other words, if you gain 10% length you gain 10% torque potential (assuming phase resistance, saturation points, and KV do not change). If you go up 10% in diameter you gain 21% torque potential. Measure them diameters, we can find out how they compare on a loose basis.

|

| |  |

| | #3 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Looks like an airsoft motor....though those little motors are used in lots of stuff.... Length really isn't the reason for more torque....more Steel in the arm, will make it more torquey.....doesn't matter if its long, fat, etc...whats gained in the length though....it will end up a wash more than likely... Other downside is, depending on the truck, is the length.....bergs and such already have clearance issues, this just seems it would compound the problem.... Later EddieO |

| |  |

| | #4 |

| Rock Crawler Join Date: Feb 2009 Location: Surprise, Az

Posts: 848

|

Looks 4-5mm longer than a 540 from the pic...pretty sure I could clear that on my berg. Would be interesting to see the results though  |

| |  |

| | #5 |

| I wanna be Dave Join Date: Oct 2005 Location: Under the 4444

Posts: 2,345

|

All my airsoft motors are flat on 2 sides, I guess so it'll "key" into the grip and not spin the can instead of spinning the gears. Hard to tell in that pic but it looks round, where did you come across that motor? I'd be all over a smaller diameter just for the servo clearance, as long as the power is as good or better than my current HH 45 turns.

|

| |  |

| | #6 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Well, like I said in my first post, the source of the motor is top secret mow. Some will know what it is by looking at it. John, The smaller, longer arm is 29mm long and 20mm in diameter The 540 arm, is 22mm long and 23mm in diameter The can is only like a couple mm longer overall than the 540 can. So I dont see the end bell colliding with the links as much of an issue |

| |  |

| | #7 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| |

| |  |

| | #8 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Ha! The difference in length makes up for the difference in diameter. The two motors should have the same torque potential holding other factors the same. The secret arm has 31.81% more length, and the 540 arm has 32.25% more cross sectional area. Makes it about a wash.

|

| |  |

| | #9 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

| |

| |  |

| | #10 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Well, by John's numbers....sounds like a wash.... The other downsides.....I doubt you can buy them unwound, so you would be stuck with a machine wound motors.....so even if there was a slight gain in torque, a 540 would still be able to blow it out of the water being handwound....I would also imagine the length of the shaft could have clearance issues in some trannys.....so lathes also could have trouble cutting it if they don't have clearance......how easy to get are spare brushes? I know the airsoft guys often throw away motors because there is no source for brushes.... Later EddieO |

| |  |

| | #11 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Test out the KV before you unwind it. If you have a tach you can figure out the speed of your hand drill, then chuck up the motor generating into a volt meter. Measure both directions, since it is fixed endbell. Divide the RPM by the lower voltage (normally advanced timing) and you get KV. If it has neo mags, the kv may be acceptably low. |

| |  |

| | #12 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Too late John, Since the motor(s) didn't cost me anything, I tore into 1. This one is a 20t. Looks like it is about 22-20g wire. Went to radio shack and got some wire to re-wind this one. That will be tomorrow though. I just wanted to get it un-would for tonight. Pics of the can and end bell. There are no holes in the can, so I am going to have to drill and tap the can. I also see, that there are bushings in the motor. Hopefully, I can put in bearings. But for testing, these will suffice. The way the brush makes contact is funny. Not sure what style this brush is, but hopefully it is one I can get.      Motor un-would. Tomorrow I will wind it, and cut the comm. More to come.....   |

| |  |

| | #13 |

| Quarry Creeper Join Date: Jul 2006 Location: pnw

Posts: 310

|

well ive already tryed this and its no secret! its a airsoft motor and your wasting your time trying to make it work. they are around 14 to 16 turn motor and have no low end res. but when i put them in my berg the wheel speed was off the charts.

|

| |  |

| | #14 |

| RCC Addict Join Date: Aug 2009 Location: Earth?

Posts: 1,698

|

I have a old Trinity Monster Maxx 21T 550 motor I wanted to rewind to a 35. I just dont have the skill, but the the idea is great. I hope yours works out. It should have a lot more torque after you rewind it.

|

| |  |

| | #15 |

| I wanna be Dave Join Date: Oct 2008 Location: Golden

Posts: 2,588

|

Oh, the power of google:   I personally feel like you are wasting your time. I don't think this will be really any better than handwound 540s and parts availability, mounting, etc are all going to be a lot of effort. The specs for this motor from the manufacturer is @9.6V = 28,390 rpm, which is about 2950kv. Torque is listed as 1.5kgf/cm, which is only about 20 oz-in. Of course, these numbers will change with you hand-winding the arm, just make sure you keep the winds tight and fill the arm with as much copper as you can fit in there. So, sorry to burst the bubble on this, but this isn't the "next big thing" but please feel free to prove me wrong. I like out-of-the-box thinking, and really hope that you are succesful with these, but I am skeptical. Awaiting your results... |

| |  |

| | #16 |

| Rock Crawler Join Date: Jun 2010 Location: Yelm,WA

Posts: 695

|

I dont know anything really about the motors so I am curious to know what determines the amount of turns (example-18T) when a motor is being handwound? This is probably a dumb question but I have not been able to find a clear answer.

|

| |  |

| | #17 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

It is simply how many times you wrap copper around the armature segment.

|

| |  |

| | #18 | |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

| Quote:

I'm interested in the results as well. | |

| |  |

| | #19 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Lars, I am re-winding the motor to a 40-42t. That should solve the low end problems. I don't think all of you are getting what I am trying to accomplish here. The MAIN thing I want, is a smaller motor, and more room for the servo. I haven't weighed it yet, but it should be a little lighter. After reading a couple of your posts, I understand, that performance will likely be a wash, but as long as I can have equal power after I re-wind it, then I will be happy. Plus, I will have gained more servo space for the 86 heep style servo I run now. Plus, JRH seems to think, that the motor will accelerate faster because of the smaller diameter arm. I don't mind the possibility, that this wont work. Like I said in my last post, these motors didn't cost me anything. I am into them 6.99 for the motor wire. So if this fails, then this thread will be the link that someone will post in someone else's thread then they ask the question. But I really don't think that it will not work. I think, that as long as I take the time to wind the motors nicely, and make sure everything else is dialed in, then it should work fine. |

| |  |

| | #20 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

The Airsoft guys hate the motors they have......they were begging peter to make them a better one when he got into Airsoft (along with the rest of us) and started posting on their forums...... Peter tested a bunch of these motors, hoping to expand the brood product line.....he was able to get them to run better. He did note, if they didn't have NEO mags, which only a couple did, they used REALLY crappy magnets that would demagnetize easily. That was the big gripe a lot of the Airsoft guys had, as they would use crazy voltage batteries to make the gun shoot faster, but they would demagnetize the magnets quickly.... I guess for nothing more than a learning experience, sure, have fun.... Later EddieO |

| |  |

|

| |