| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: May 2005 Location: CITY of CHAMPIONS!!

Posts: 2,086

|

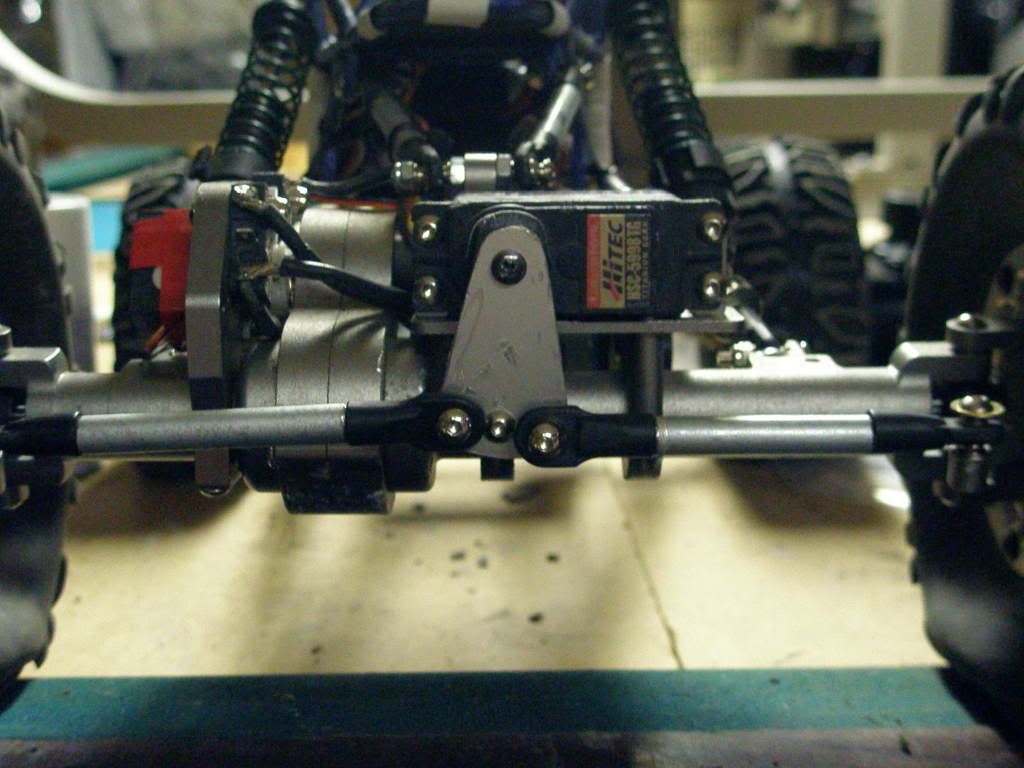

well i have become increasingly irritated with the steering on my new berg tuber. i just cant get it dialed in to where i like it. It has me very frustrated. So far the only thing i don't like about this truck! If i use the tie rod on top of the knuckles with a drag link from the servo to the knuckle, i cannot get full steer left and right because the servo horn isn't long enough to throw the full steering. I can't use a longer servo arm unless i put the tie rod under the knuckle to allow room for a longer arm. then the tie rod hangs too low.. under the axle housing, not going to work. Cant flip the arm to the top of the servo because first rollover would break the arm off. so i tried to tie rods to the same mounting point on servo arm, one in the front, one in the back, this seemed to work, however i didn't like the way it looked offsetting. I could deal with the look but, i found out at the raceway hobbies comp, this put the screw too close to the axle housing and it would bind up my steering not allowing me to steer at all. So its out the window. I tried mounting them both in front of the arm but that stuck out way too far even past the front edge of the tires. This killed my approach angle. so i saw someone post this solution and i thought i would give it a try.  My only concern is that the outside tires turn much further than the inside tire. does anyone see a problem with this. is it going to effect any performance or put any abnormal stress on anything. you can see it in the next 2 pics.. Thanks   |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Feb 2008 Location: no more lockers

Posts: 400

|

rockbound i tried that steering linkage in order to try an optimize ackerman but all i could come up with is the opposite of what you need. in your picture shows exactly why i went away from this steering linkage set-up your outside wheel is steering tighter than the front and that's not good , you want the inside wheel to steer tighter . with that set up you will get a bad slip angle and this will cause the truck to push like a dump truck while on throttle i tried all sorts of different positions with that type servo horn and when i finally got the ackerman right the linkage was not idea and very steep . i am working on a solution and will post it as soon as i find one

|

| |  |

| | #3 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

I just posted this in Jason's thread but since it would be helpful hear I will post it again. One thing I have noticed is Ackerman's angles don't mean squat when the front end is locked, as a mater of fact I think having the outside tire turn sharper helps you turn better with a locked front end. http://media.putfile.com/007-85 |

| |  |

| | #4 |

| Im Brandon  Join Date: Feb 2005 Location: Colfax, CA

Posts: 8,156

|

For a quick fix just set your front end with some toe out. More of a bandaid but it can work.

|

| |  |

| | #5 |

| I wanna be Dave Join Date: May 2005 Location: CITY of CHAMPIONS!!

Posts: 2,086

|

thanks guys i guess i will just run it and see how it reacts. kamikaze, doesn't that double link on the front get in the way of your approach? i had mine set like that and it hit everywhere!! |

| |  |

| | #6 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

I haven't had a problem with it, its up higher than a tie rod would be. Its been in 3 comps, 3rd place at the east coast championships, 2nd place with joe driving at an SERCRC comp, and I won teh MidTenn comp saturday. Needless to say I'm happy with it.

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Feb 2008 Location: no more lockers

Posts: 400

|

with a lcoked front axle i believe ackerman is more important because the axle is locked both wheel will travel the same number of revolutions as it travles the arch but one travels a further distance so the distance needs to be made up with ackerman to reduce slip angle . now this is going from road racing off road suspension theory . and i have played with it a whole bunch racing nitro touring cars with solid front axles /spool and it does indeed make a difference in front end traction in a turn . this should mean it applies to steering any rc car even a at the slow speed of a crawler . front end traction is front end traction . will you feel it driving between a truck with proper ackerman and one with whacked out ackerman ? probably not but it will make small advantages in steering .

|

| |  |

| | #8 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

Here is a comparison pic. Sorry but my front tires are flat on my comp truck.......

|

| |  |

| | #9 |

| RCC Addict Join Date: Aug 2005 Location: VARCOR

Posts: 1,826

|

Part of the problem with this on RCs, is that we are using a servo which uses a rotational movement instead of a straight linear movement (i.e. ring and pinion). Looking at your pic from the front, if the servo moved 45* to the left, the link mounted further to the left would move just as much up as it did to the left, whereas the right mounted link spent more time moving to the left than it did upwards. The tire opposite of the direction of travel of the servo horn will have more travel in the right/left plane. Confused yet? It doesn't go away (it won't since it will always be a rotational movement servo driving rotational movement knuckles), but it is improved if both links are mounted at the same point on the horn, as shown in Kamikaze's video. |

| |  |

| | #10 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

Here is my turning radius. http://media.putfile.com/010-32 |

| |  |

| | #11 | |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

| Quote:

| |

| |  |

| | #12 |

| I wanna be Dave Join Date: May 2005 Location: CITY of CHAMPIONS!!

Posts: 2,086

|

i also noticed that at full lock the drive pin on the inner axle is no longer inside the outer shafts cup. i was a little concerned with that. what do you guys think of this?   also here are a couple short clips of the turning radius with it set up like this. notice with the pics after the vids how far the truck traveled 90 degrees from the start point. it still isn't the same right to left.     |

| |  |

| | #13 |

| Quarry Creeper Join Date: Jun 2007 Location: Waipahu

Posts: 426

|

Here's a set up that I'm trying out. I used an angle bracket and drilled two holes to mount on the draglink and one for the steering arm.   So far it held up. Alan. |

| |  |

| | #14 |

| Rock Crawler Join Date: Mar 2008 Location: Arizona

Posts: 578

| I put a 2mm shim under the servo plate and it allows me to mount a longer servo arm and get full stear and enough clearnce to set it up properly.

|

| |  |

| | #15 |

| RCC Addict Join Date: Feb 2005 Location: Minneapolis

Posts: 1,496

|

Spint, I think you would get more leverage from your servo if you mounted your links further out on the steering knuckles. Same is true if you can move your steering link closer to the servo (up on your bracket).

|

| |  |

| | #16 | ||

| I wanna be Dave Join Date: May 2005 Location: CITY of CHAMPIONS!!

Posts: 2,086

| Quote:

Quote:

thanks  | ||

| |  |

| | #17 |

| Quarry Creeper Join Date: Jun 2007 Location: Waipahu

Posts: 426

|

I am looking for more clearance between the knuckle and the tire without increasing my track width. I've looked into the dual link set up and thought I'd try something different. I'm trying different foams now to stand the tire up and limit the side flex.

|

| |  |

| | #18 | |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

are you geared differently between the two motors? it seems like the front is dragging the rear around even though the rear is moving. | |

| |  |

| | #19 |

| I wanna be Dave Join Date: May 2005 Location: CITY of CHAMPIONS!!

Posts: 2,086

| |

| |  |

| | #20 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| |

| |  |

|

| |