| | #1 |

| Newbie Join Date: Nov 2008 Location: Grande Prairie, Alberta

Posts: 17

|

Has anyone tried making a dig system that works more like a clutch for a 2.2/1.9 shaft driven crawler? And if so is the ability to feather the clutch an advantage over the lock/unlock action of a normal dig? The idea would be if the servo pulls harder the clutch burn off less and gives more power to the rear or vice versa for a rear dig if i were to have one front and back. Matt. |

| |  |

| Sponsored Links | |

| | #2 |

| On the lookout for Rocks  Join Date: Mar 2006 Location: Monroe, Louisiana

Posts: 3,711

|

This can be done with a dual motor dual esc setup.

|

| |  |

| | #3 |

| Newbie Join Date: Nov 2008 Location: Grande Prairie, Alberta

Posts: 17

|

Yes but then its a MOA setup and doesn't fit into the ruleset of a shaft driven crawler. Digs do though. I was wondering if there would be an advantage in real use of having a clutch instead of a locking device.

|

| |  |

| | #4 | |

| Rock Crawler Join Date: Jun 2007 Location: Great Britain

Posts: 935

| Quote:

I imagine the system would work very well if used with a aircraft style radio. It would certainly have its advantages in certain situations and you would get all the effects of dig as well a clutch style system. | |

| |  |

| | #5 |

| Rock Stacker Join Date: Jan 2008 Location: Morrisville, NC

Posts: 80

|

A dig built similar to an automotive style clutch would have one great advantage that I can see, It would not have those darn interlocking parts that bind up in current dig designs. But.. I suppose that a clutch style dig in the "drive" and "dig" positions would need to be similar to an overtightned slipper. That's quite a bit of spring pressure to overcome with a servo. Obviously, some form of mechanical advantage could be designed into the mechanisim. So get to it! |

| |  |

| | #6 |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

|

If I'm reading this right, I think others have done something similar to a clutch on a driveshaft dig. Instead of the locking pin that locks the rear axle, they use an o-ring. The harder the servo pulls, the less it slips. Lighter pull, less resistance from the friction between the o-ring and the slider (clutch plate).

|

| |  |

| | #7 |

| Newbie Join Date: Nov 2008 Location: Grande Prairie, Alberta

Posts: 17

|

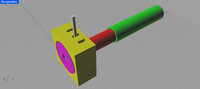

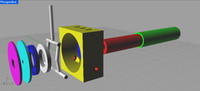

My intention was to use the "Clutch Basket/Slipper" out of an LST. Im going to just use a 8-1 or so push rod setup on the servo and a trust bearing on the end. Ill end up with around 2.4 linear pounds of force with a normal servo arm setup or around 10 pounds with a cam setup ive been thinking of. In a clutch setup all you need is a couple of mm's of travel so i can REALLY use mechanical advantage here.     Obviously a very basic design, but if what im hearing is right then it would be a good design to look further into building. I have personally done lots of playing with the slipper on my crawlers to find that i like just a touch of slip in order to ensure that i still have the power when i need it but its a bit more controllable in "High Grip" situations. To be able to control that on the fly would be great. Matt Last edited by Fuzzy; 11-09-2008 at 12:20 AM. Reason: Added pics |

| |  |

| | #8 |

| Pebble Pounder Join Date: Apr 2006 Location: Mt Blanc; France

Posts: 168

|

seems to be interesting ideas , this could do something more sensitive (choosing the amount of traction of the rear is a great pls over only front wheel drive ) and quicker than the actual digs to re-engage or lock and need many times less servo arms travel to work , what means more torque and could be done with standard or mini servos it's also possible to make a pick-up actuator mechanism with a cam form that locks itself in engaged position , wich could also been realised by a 90° servo arm position one last though : the clod buster steerring cantilever or any servo saver half has the required form to tight or lose a slipper style mechanism or a ball diff Last edited by SilverRidge; 11-09-2008 at 11:49 AM. |

| |  |

| | #9 |

| Newbie Join Date: Nov 2008 Location: Grande Prairie, Alberta

Posts: 17

|

That was the Cam idea, but implementing it on a linear axis to increase the strength as opposed to a rotational axis on both end for compactness. also, because its a Cam once you reach the peak tension, there is 0 load on the servo, the linkage bears all the weight. I was also considering adding a second set of plates to it on another trust bearing but on the opposite side to make a disk brake, so you'd have clutch and brake on the rear end. Could be interesting.... For Christmas my Girlfriend got me a Mini losi crawler so I'm going to make that my "Project Truck", ill be building this for sure and a couple of other ideas like a Stepper motor in place of a dc brushed one. Ill read through the rules a couple of times to see if the Clutch dig is legal, and if so i might make a couple of them for scorpion tranny's. Matt. Last edited by Fuzzy; 11-09-2008 at 03:34 PM. |

| |  |

| | #10 |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

|

I thought about integrating a disk brake into the dig at one point. In the freewheel position you could increase the clamping pressure of the brake with a 4th channel, and if you need it locked, you have the mechanical locking that the current digs provide. But ask yourself if it is really worth it. I did not pursue the idea because an MOA rig can do all of that, have higher GC, with no tranny in the middle.

|

| |  |

| | #11 |

| Newbie Join Date: Nov 2008 Location: Grande Prairie, Alberta

Posts: 17

|

Meh, I guess you just dont know if its worth it until you try it... Im gonna mill all the generic parts ASAP and make the casing as soon as I get the mini. I guess i just wanted an idea as to weather its been done and if it had, did it work. Matt |

| |  |

| | #12 |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

| You've got the right attitude, never let someone squander your ideas. If you need any help, drawing, machining advice, etc, let me know, I am a Mechanical Engineer.

|

| |  |

| | #13 |

| Newbie Join Date: Apr 2010 Location: Singapor3

Posts: 11

|

I am reviving this old thread with some enthusiasm.. I may not have the equipment and tools to build one DIG, but I had just one simple off-the-shelf solution for a simple Clutch-Brake DIG system. Send me some cash if my idea works..  Rig would be a shafty crawler such as AX-10 as an example. If I could use this similar slipper clutch off an onroad car.. Mount this slipper clutch at the rear drivetrain and tighten it until it didn't slip, but not excessively tightened. It has to slip when the rotation is jammed. Then a servo can be used to push a metal shaft or pin traversely through the holes on the face of the slipper clutch to jam up the rotation. We now don't need a high torque servo to make it work since the servo purpose is to push a rod in or out through the holes. In fact a micro servo might just work. Practically serving as a locking DIG system. What do you guys think ? This may seems to be the most simplest of all design since we don't have much engineering work to be done..  |

| |  |

| | #14 |

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

|

I think your best bet would be to use a "cone-type" clutch. It requires a lot less pressure due to the two pieces wedging together. And also the idea of a spring holding the clutch engaged, and a servo releasing the clutch would be better. I think the only problem would be getting a 3 position (engaged, freewheel, locked) type dig. With your slipper clutch idea, you still don't have a way to lock the driveshaft for digging. It's more like a limited slip or locked inter-axle differential. |

| |  |

| | #15 |

| Newbie Join Date: Apr 2010 Location: Singapor3

Posts: 11

|

The drive shaft goes to the spur gear.. the metal shaft that is shafted through the holes will lock the spur gear and thus the drive shaft to the rear wheels, while the motor will rotate the other halves of the slipping clutch. Just an idea.. may not actually end up working on one but its still a simple idea. |

| |  |

|

| |