| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

|

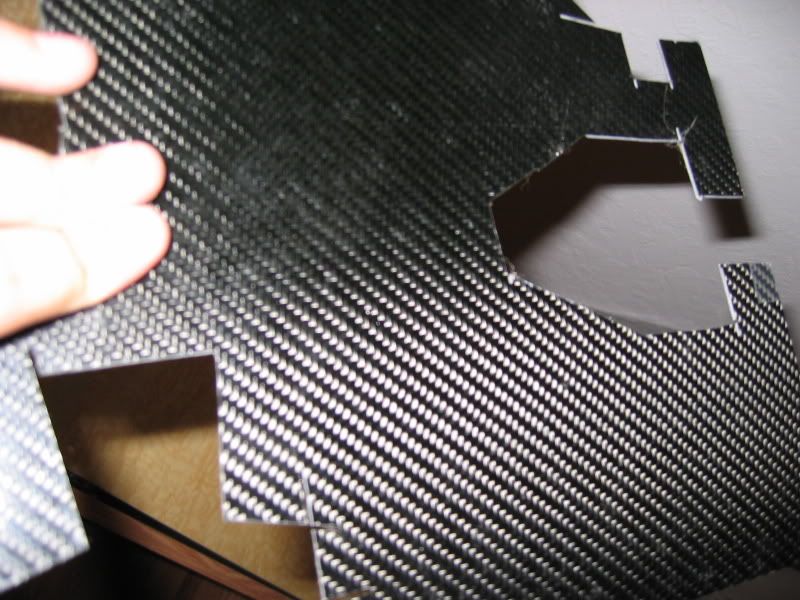

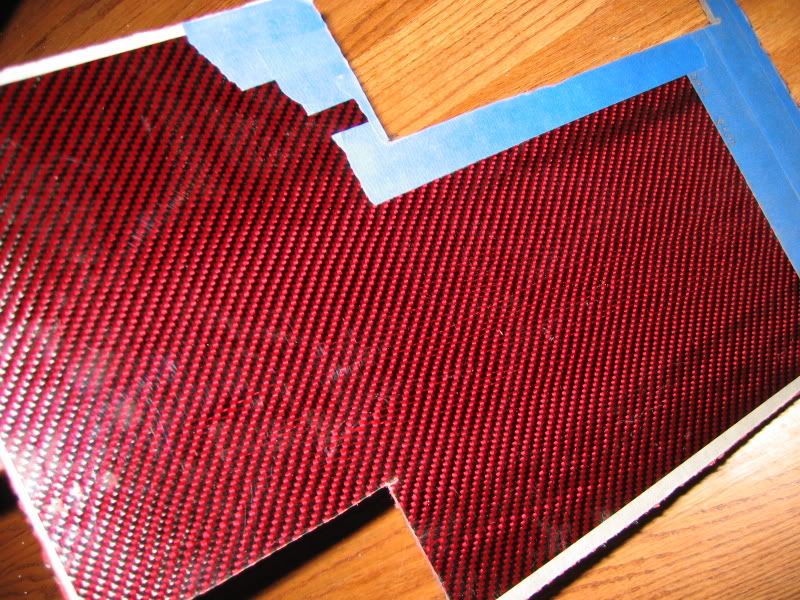

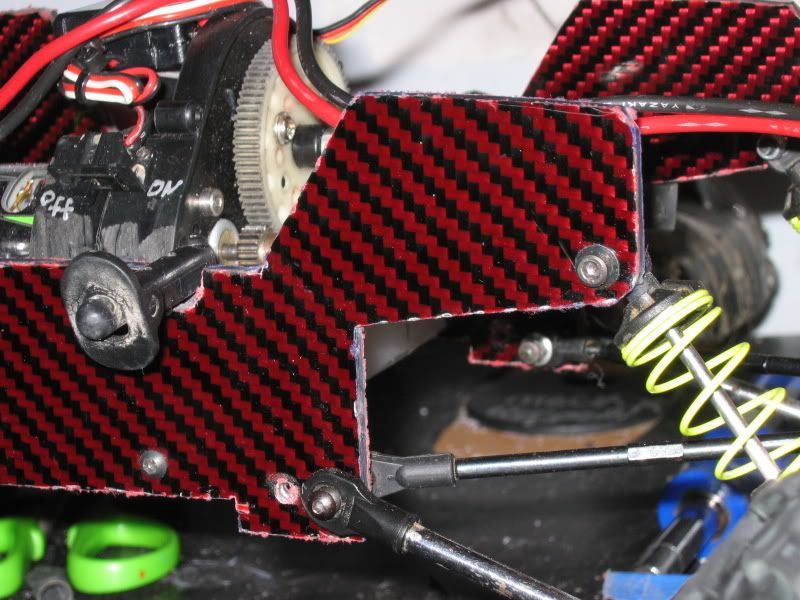

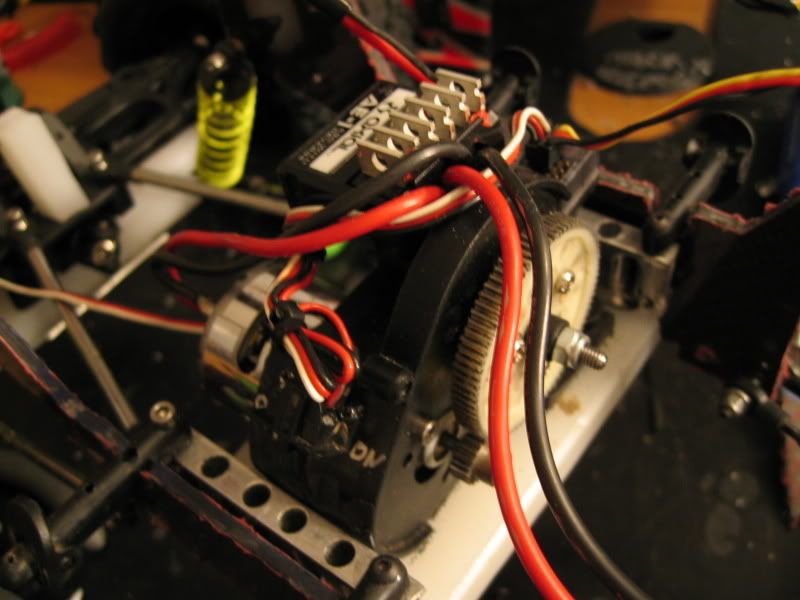

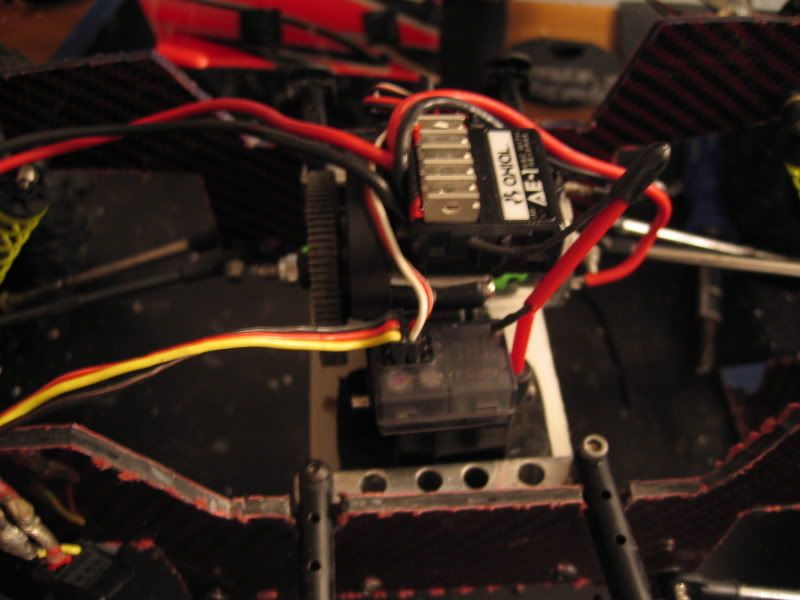

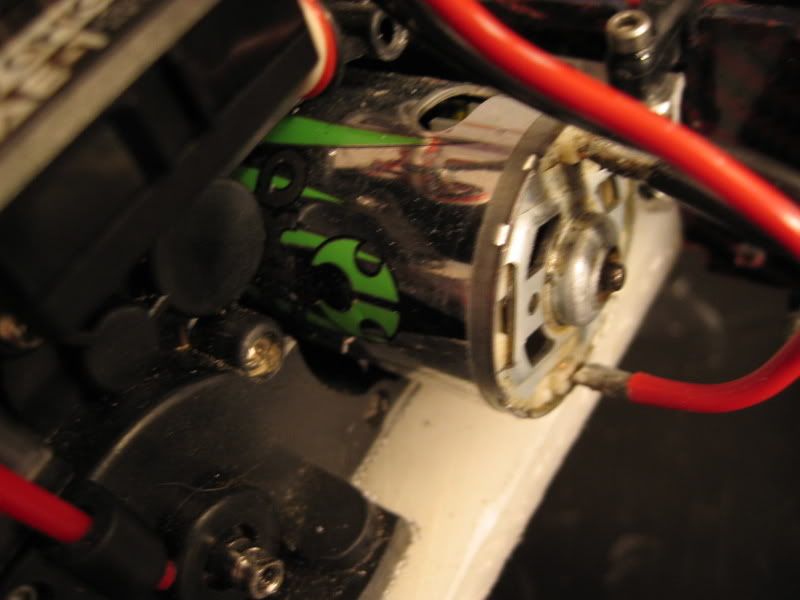

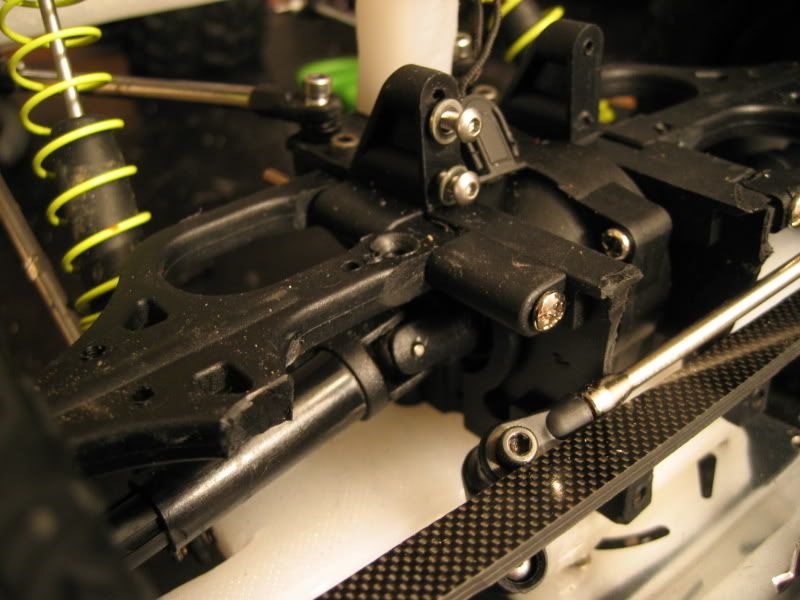

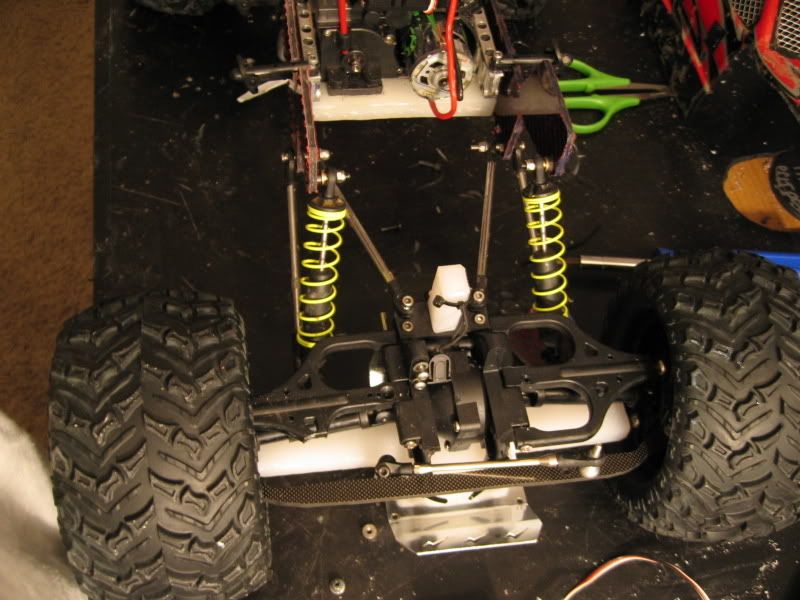

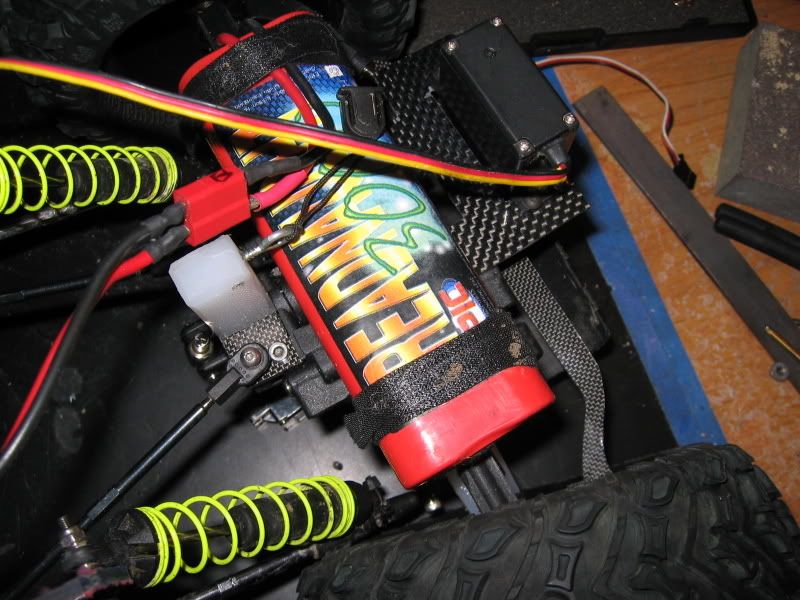

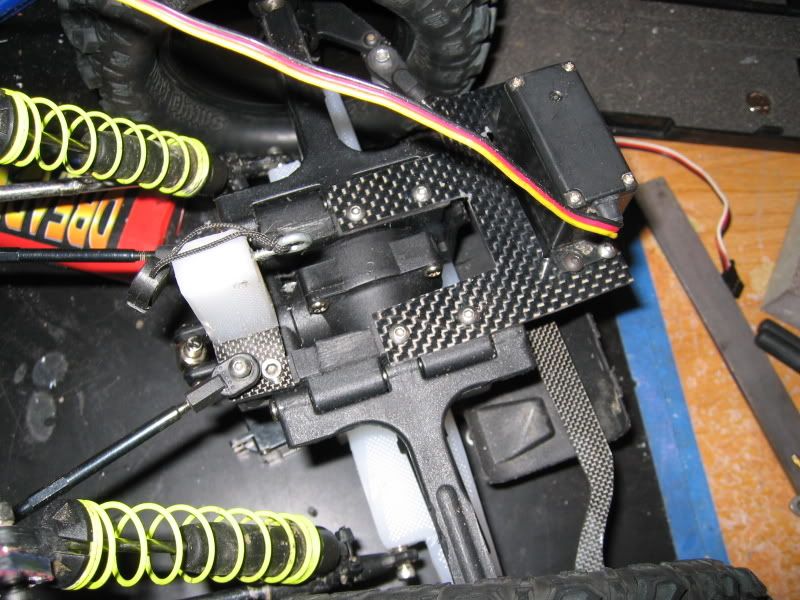

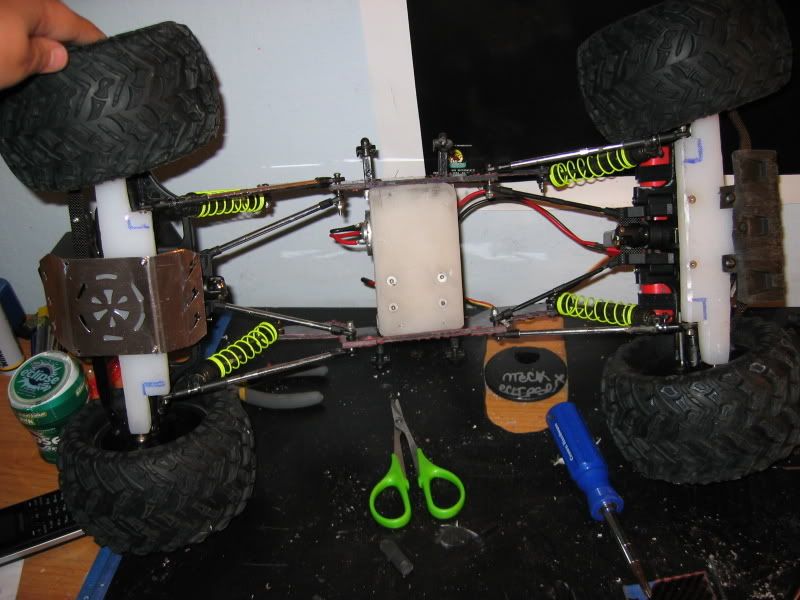

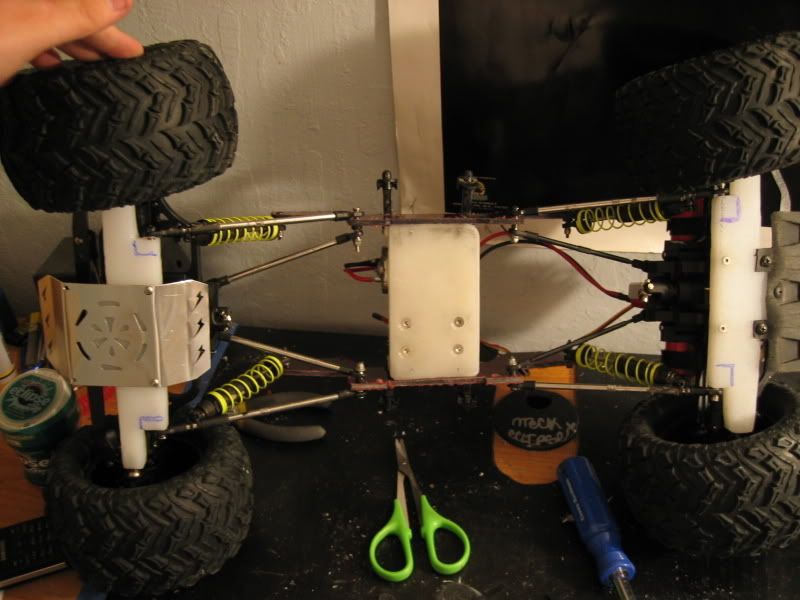

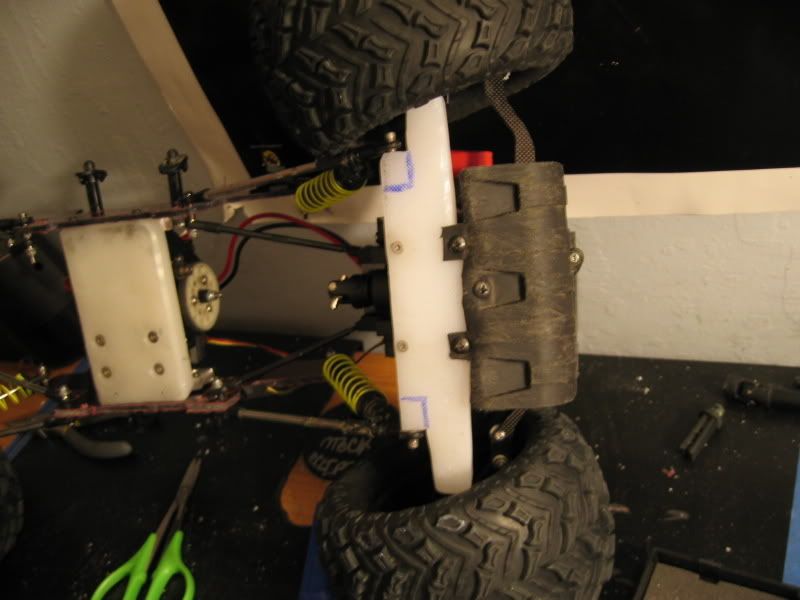

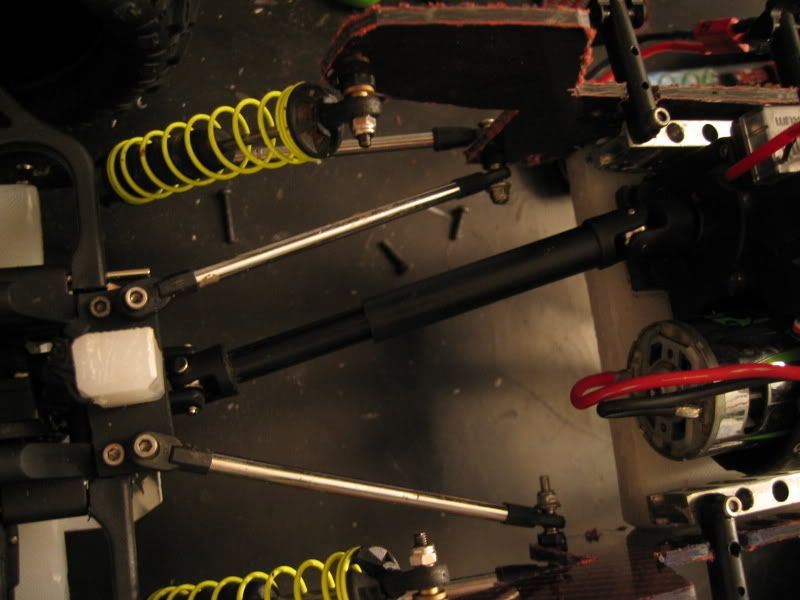

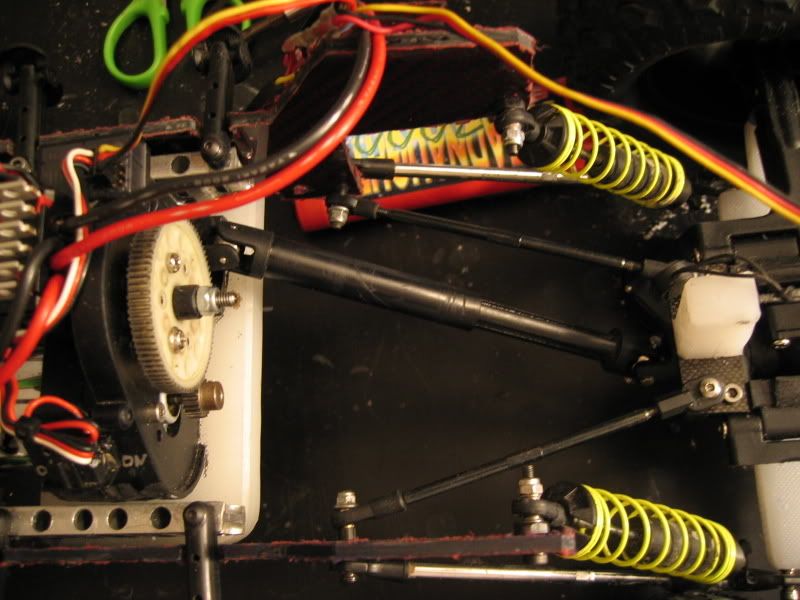

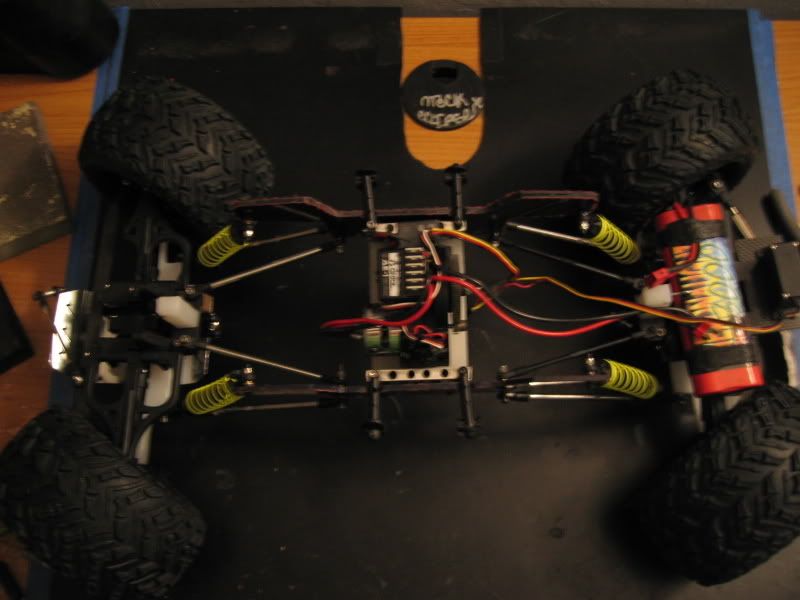

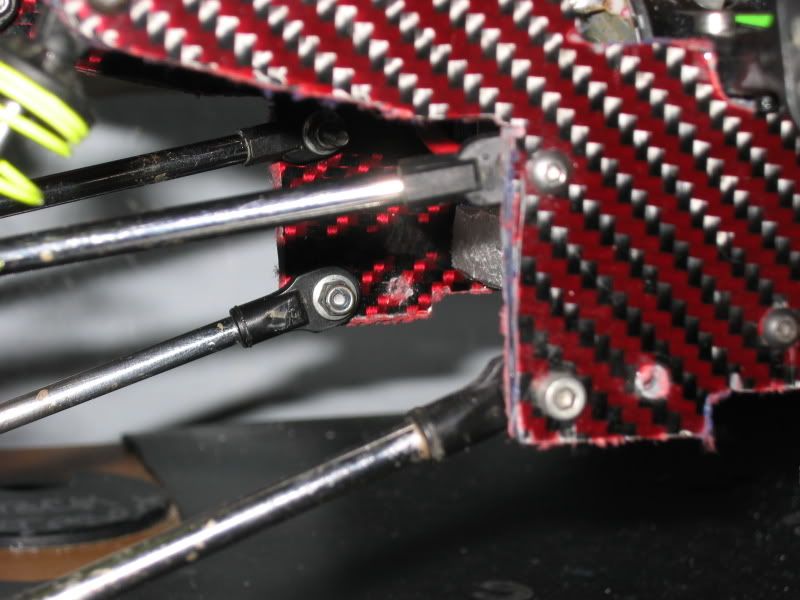

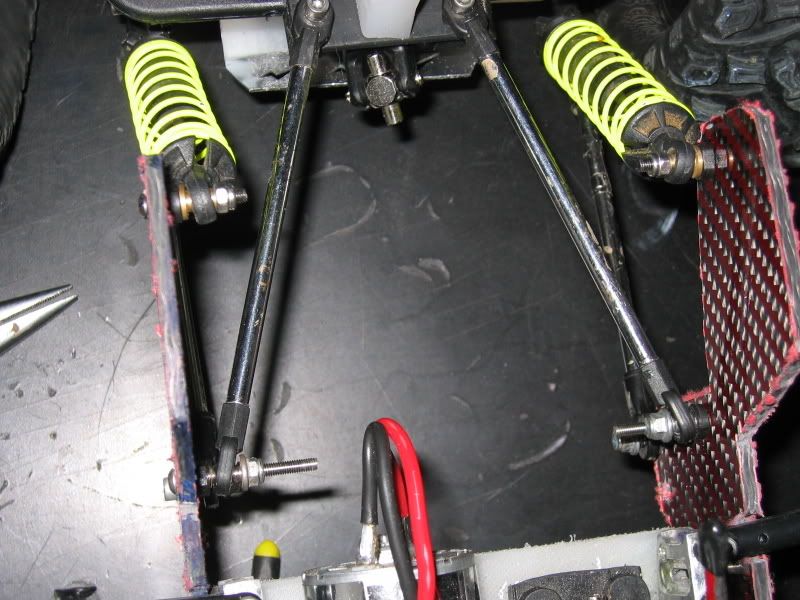

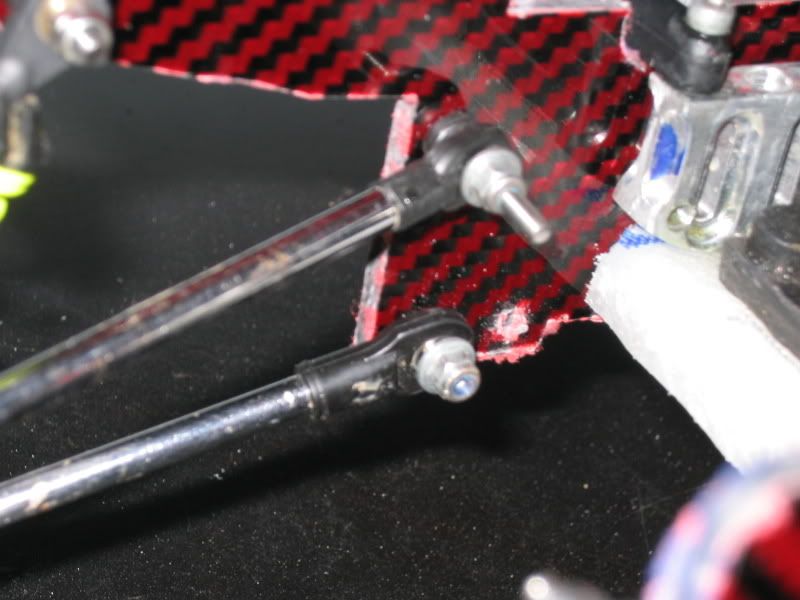

hey guys im preety new to crawling but certainly not to rc.i was playing with my friends new ax 10 and decided i liked it and knew i had lots of parts laying around turns out almost enough to build a tmaxx.i like to biuld things so i wanted to try biulding my own crawler.i only spent 15$ so far. this is what i came up with..guys please tell me how i did and what i did wrong please (it helps me alot). now I introduce you to BLACK WIDOW   maximizer 1/2 on hpi dirt claws  carbon fiber i used     the pede tranny i bought for 15$   im using a axial 27t motor i think its a perfect combo  overview  the tmaxx parts that i had laying around all got used   articulation    servo/battery mount    i use alot of delrine/cutting board parts to make it super sturdy     i had it running for a little while untill i broke my driveshafts      16inch wheelbase hex to hex   and cant forget 4wheel steering  btw if anyone has any servos and or tmaxx driveshafts they could sell me that could get this project rolling in the right direction.. thanks guys hope you like it |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: May 2004 Location: Spanish Fork, Utah

Posts: 55

|

Looks pretty impresive for only $15. You are probably going to want to get some vertical seperation on your links at the chassis end.

|

| |  |

| | #3 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| |

| |  |

| | #4 |

| Rock Stacker Join Date: Mar 2008 Location: Canyon Country

Posts: 95

|

I think what he was refering to was to raise your upper link mount on the chassis....on my super I have about an 1" of seperation between the upper and lower link mounts on the chassis. I like your idea though, I was thinking about building a super using Hpi Savage axles. |

| |  |

| | #5 |

| Newbie Join Date: Dec 2008 Location: Orangevale

Posts: 17

|

Have you tested it it looks sweet bro i cant wait to see action shots

Last edited by joemama32; 01-13-2009 at 09:57 PM. |

| |  |

| | #6 | |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| Quote:

| |

| |  |

| | #7 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| |

| |  |

| | #8 |

| Rock Crawler Join Date: Jun 2008 Location: Lemont, IL

Posts: 551

|

way to go on building your own crawler. so, you turned and independent suspension to a solid axle with delrin plates huh? there is no right or wrong, it either works or it doesn't. just gotta try new things(doesnt seem like you have a problem doing that anyway) |

| |  |

| | #9 |

| Quarry Creeper Join Date: Nov 2007 Location: Northern

Posts: 311

|

I see you have a mix of large revo ends and standard traxxas rod ends. May I suggest using all revo ends. The standard traxxas rod ends could make a weak link for a super crawler.

|

| |  |

| | #10 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| thanks

|

| |  |

| | #11 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| hahha lol you are the only one who noticed that so far but the problem is the revo ends fit on the pinions but not on the pede tranny..any suggestions?

|

| |  |

| | #12 | ||||||||

| Quarry Creeper Join Date: Nov 2007 Location: Northern

Posts: 311

|

Use what you have until they break than make your own links. I make my links from revo ends and the following from mcmastercarr....

| ||||||||

| |  |

| | #13 | |||||||||

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| Quote:

by any chance you got a link or pics of how you did yours? | |||||||||

| |  |

| | #14 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

|

update: i moved the upper links like you guys said.    |

| |  |

| | #15 |

| Quarry Creeper Join Date: Nov 2008 Location: morristown

Posts: 375

|

it looks good can you post a vid

|

| |  |

| | #16 |

| Quarry Creeper Join Date: Nov 2007 Location: Northern

Posts: 311

|

It's quite simple and with the fabricating skills you have, you shouldn't have a problem and should have the tools required which is a tape measure/digital calipers, file and a haxsaw. Let's say you need to make a custom 6 1/4" link. measure the revo end from the center of the ball to the end (I'm not sure of the exact dimension but let's assume it's 5/8"). So you're aluminum 1/4" sleeve should be cut to 5" (6 1/4" - (5/8" x 2)= 5". File one end of the threaded rod and install the rod end. Insert the cut sleeve on the opposite end of the threaded rod and make a mark to cut the threaded rod approximately 5/16"-3/8" further to accept the other rod end. Cut, file, assemble and you're done. |

| |  |

| | #17 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| |

| |  |

| | #18 | |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

| Quote:

| |

| |  |

| | #19 |

| Newbie Join Date: Sep 2008 Location: Saint John NB

Posts: 31

|

i see you used cutting board to lock your independent suspension, may i suggest fabbing some mini shock towers and using solid links to further strengthen the front and rear ends.

|

| |  |

| | #20 |

| Pebble Pounder Join Date: Dec 2008 Location: hercules

Posts: 124

|

ye good idea but they are pretty strong and i dont have spae as the servos are in the place of the mounts

|

| |  |

|

| |