| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

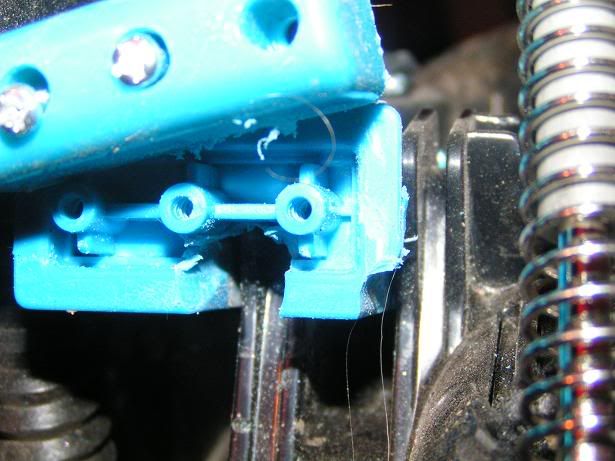

I have built 3 1/18 Nylints. This is my first 1/6. I'm starting with just the chassis. First step was to inboard the front shocks. The rear I moved them in about an inch from each other, This way they will always be pushing down for tratcion and they can't split about no matter what my flex is. I did this by fab'ing a rear lower shock mount. The rear top shock mount was just something I found on another RC I had. I'm working on something different on the front for more flex. ( thats hard ) Here is a pic of how I did the shock mounts for now. The rear will stay only the front will probley change.   I can also put a front tire up on 2 cans plus the extra cardboard. I believe we measured it at around 10.5 inchs. I'll post some more pic's when I get more done. This next pic isn't my Jeep but that's the way I'm doing my Tummy tuck. Looks factory the way he did it. Last edited by run2jeepn; 12-20-2005 at 07:50 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| Pebble Pounder Join Date: Oct 2005 Location: AZ-Phx

Posts: 111

|

how does that rear set up work? i was thinking off some thing like that

|

| |  |

| | #3 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

This pic here isn't my Jeep, but it is my friends. I'm doing the tummy tuck the same way he did. Looks great. ( looks factory ) I my tuck mine up a little more. I plan on cutting the tabs off the belly also that stop all the droop. I'm just going to make limiting straps that limit my droop were I want it and were I can adjusted also.  I plan on using a lexan body for mine as well. I'm using a HPI Jeep Wranger Rubicon Savage body.  Here are the spec's on it. SPECS: Length: 18" (457mm) Width: 8.5" (216mm) at rear wheels-widest point Width: 7.6" (194mm) behind front wheels-narrowest point Height: 5.25" (133mm) Wheelbase: 12.5" (317mm) |

| |  |

| | #4 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

With having the shocks mounted like these they won't split apart. They can't. One more thing you can't see in these pics. Is were I trimmed out some of the blue center link and the black tabs under the center pivit arm. I even sanded down the corners off them so it wouldn't hit the axle sooner. I'll post some pic's soon of this.

|

| |  |

| | #5 |

| Pebble Pounder Join Date: Oct 2005 Location: AZ-Phx

Posts: 111

|

cool, alot of people are telling me that cutting the taps on the belly is bad:? only prob i have wit it is wrapping under, so imo all u need is limiting straps, which u said. cant wait to see ur jeep |

| |  |

| | #6 |

| RCC Addict Join Date: Jul 2005 Location: Provo

Posts: 1,868

|

be carefull with those electronics and cant wait to see some more pics!

|

| |  |

| | #7 |

| Pebble Pounder Join Date: Nov 2005 Location: South Range

Posts: 109

|

My friend cut just the body tabs, I don't think he knows about the axle ones. He had to add limiting straps as well, but it seemed to work pretty good. I think this is what I will do.

|

| |  |

| | #8 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Here is a better picture of how I cut the blue center pivit arm. It's kind of hacked up right know, but I'm going to sand it all down smooth.  On the cutting off the tabs. Limiting straps will fix that. I just think some droop not a lot, but some is a lot better then none. I don't see any 1:1 crawlers that have limited all there droop. They all have a little drop. These 1/6 Nylint don't have any whats so ever. Here is a little better pic of the rear shocks.  My goal with this is to make the Nylint crawler light as possible. By cutting the belly off and changing the body to lexan and cutting even more off the frame that isn't needed. If I can't find a use for it I'm cutting it off. I'm going to add many BB's to the tires to lower the COG. I want the bulk of the weight down low. |

| |  |

| | #9 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

I figured how to get more flex out of the front. The biggest part of the front not flexing good is that the those big arms hit the axle. I found away to get them to clear no problem. But it's to hard to write it out. I'll just have to do it and and post some pic's. |

| |  |

| | #10 |

| Pebble Pounder Join Date: Nov 2005 Location: South Range

Posts: 109

|

Don't keep me up all night waiting!

|

| |  |

| | #11 |

| Quarry Creeper Join Date: Aug 2005 Location: Crawlorado

Posts: 333

|

have you wheeled it at all? not trying bash, but I clearanced everything and could pick a tire 12.5" off the ground, but found I made the suspension way to soft and it would randomly put an axle vertical, killing my forward motion (because a tire was in the air). Just something to think about

|

| |  |

| | #12 | |

| Quarry Creeper Join Date: Aug 2005 Location: Crawlorado

Posts: 333

| Quote:

| |

| |  |

| | #13 | |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

| Quote:

| |

| |  |

| | #14 |

| Pebble Pounder Join Date: Nov 2005 Location: South Range

Posts: 109

|

Perfect sense, it is the same as doing a 3/4 elliptical suspension on a leaf sprung vehicle (a.k.a. buggy spring). Did you buy or make those mounts? I currently just angled in my shocks just for some more flex, but I would rather mount them like you. Granted with how far in those springs are mounted, I don't think they will create a whole lot of downforce due to the large moment arm. I think I will mount them out as far as I can without the spring decompressing.

|

| |  |

| | #15 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

The mount I made myself. It was some square tubing from some window. I'm going to play with the rear shock postions some, but I think they are staying there. The way I made the lower shock mount I can change it real easy. Just drill and bolt it back.

|

| |  |

| | #16 | |

| Quarry Creeper Join Date: Aug 2005 Location: Crawlorado

Posts: 333

| Quote:

| |

| |  |

| | #17 |

| RCC Addict Join Date: Sep 2005 Location: ...Here & There

Posts: 1,590

| |

| |  |

| | #18 | |

| Newbie Join Date: Nov 2005 Location: Portsmouth

Posts: 14

| Quote:

I don't see how you can use 'less effective' to describe how those "shocks" work, they are merely springs, if he was using actual oil dampened shocks it would be a different story. For what he's using and how he's using it, it seems like he's further ahead than most of you. Maybe just because it's different it isn't exactly wrong or bad. | |

| |  |

| | #19 | |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

| Quote:

| |

| |  |

| | #20 | |

| Pebble Pounder Join Date: Nov 2005 Location: South Range

Posts: 109

| Quote:

HERE IS THE IMAGE: http://us.f1.yahoofs.com/bc/3fb7136e...c8JiDBsJO7TrPc As you can see, if the point of rotation is the center of the axle, the angled spring could have more leverage, but because it is angled, it would actually have a force in the horizontal as well as vertical direction that when combined (using trig.) will equal to the total force of the spring. So say you have 50 pounds of downward force, and the angled spring is at a 45 degree angle. The angled spring is 3.5" from the center of the axle, the inborded springs are say 1.5". Then the downward force of the angled spring is Sin(45)*50pounds=35.35pounds. Now, that downward force is located 3.5 inches from the axle. So the torque from the angled spring is 35.35*3.5=123.74 inch pounds. Now lets look at the inborded springs. They have a vertical force of 50 pounds and are 1.5 inches from the center of the axle. 50pounds*1.5inches=75 inch pounds. Therefore in this simplified version, the angled springs exert more downforce on the tire than the inborded springs. Now, if you want to look at it in even greater detail keep reading. Since the force a spring exerts varies with how far it is compressed or extended, the force will most likely not be the same in both situations. In looking at the pictures that run2jeepin has posted, it appears his springs are more compressed at ride height when mounted in the center. This means that they will have a greater downforce than the angled spring. So while under compression or while it is drooping, it will have a greater downward force than the angled spring. However, the leverage of the force plays a big role as shown before. Therefore, since the angled spring setup is 1.65 times larger in torque than the inborded springs, the downforce of the inborded springs would have to be 1.65 times greater than the angled springs, and since the spring constant is the same for both, it means the inborded springs would have to be compressed 1.65 times farther than the angled springs to exert the same amount of torque (I hope you followed that). However, this is only true while the springs are under compression, and run2jeepin is correct when he says that as soon as the angled spring unloads completely it will have no downforce other than the weight of the tire and axle, and when this point is reached, his design will have more downforce for traction. My solution to this would be to go find longer springs for the angled setup. If you have any questions please let me know, I tried to make it clear but I will do my best if you don't get something. Christian Last edited by MTUJeeper; 11-26-2005 at 10:25 AM. Reason: It screwed up my "drawing" | |

| |  |

|

| |