| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Pebble Pounder Join Date: Jul 2004 Location: St.louis

Posts: 114

|

What are you guys using to fill in tholes in hard plastic bodies and like smooth out body lines? using bondo? si there something easier to use then bonbo since you have to mix it up and junk. i'm wanting to start a scale build soon and the body i want/hope to use has some holes that need to be filled.

|

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Nov 2006 Location: RENO, NEVADA

Posts: 332

|

i use bondo, its not to hard..

|

| |  |

| | #3 |

| Rock Crawler Join Date: Dec 2008 Location: Marengo, Ohio

Posts: 980

|

I use the bondo brand spot/glazing putty, comes in a tube and is red. Just gotta keep in mind not to apply it very thick or it doesnt cure properly.  |

| |  |

| | #4 |

| Pebble Pounder Join Date: Jul 2004 Location: St.louis

Posts: 114

|

ah so they do have something thats not a royal pain to use. haha cool i'll look for it

|

| |  |

| | #5 |

| RCC Addict Join Date: Apr 2005 Location: Seattle

Posts: 1,437

|

What you want to use (at least for Styrene bodies like Tamiya) is plastic modeling putty. You can get it at any hobby store. Works great.  |

| |  |

| | #6 | |

| I wanna be Dave Join Date: Aug 2007 Location: santa monica

Posts: 3,687

| Quote:

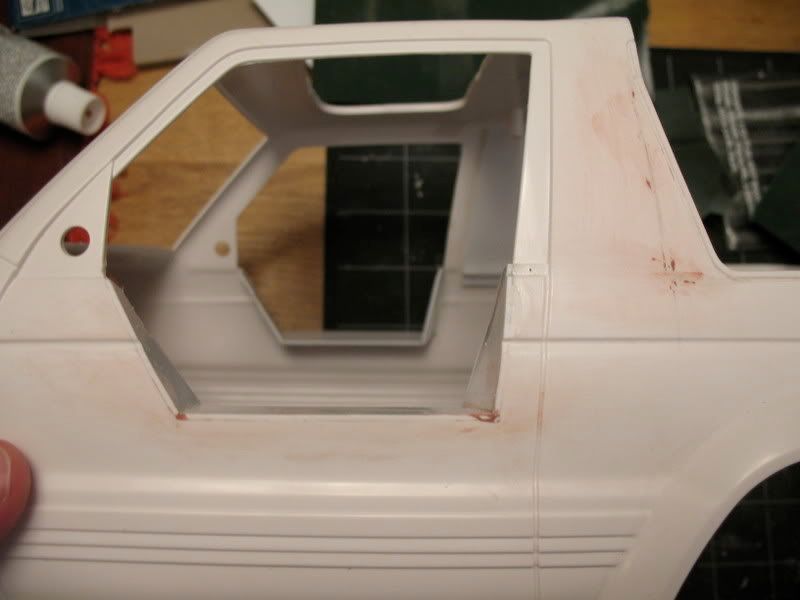

although I prefer to use actual styrene to fill holes...not styrene dust in the solvent but actual styrene. Here's how I do it: get some styrene and cut a strip from a relatively thicker sheet, 040 or thicker. take a lighter and hold it lit under the center of the strip, far enough to only heat it, not burn it. shortly the center will get soft and then grab the end, then pull gently on it. This will stretch it and create really thin styrene string. use this really thin stuff for filler. cut it to length, place it on the cut. wet the area generously with tenax7r. get the whole thing wet, or if its longer than 2" or thereabouts work in sections. then take a utility knife or spatula of some sort to press the string into the cut. the tenax will have softened it so you can really manipulate it into the gap. dont worry if it sticks out from the surface. you can file/sand it down later. in fact, its preferred. this is the piece in place, glued with tenax to stay put.  then after I filled it with styrene, pressed in using a spatula after its softened with the solvent.  I could have used thinner stuff but was planning on filing/sanding anyway so I left it really sticking out. then took a quick pass over the top 1/3 of the joint with a metal file to see how it took.  at this point you can see tiny divots and scratches still. you could fill with styrene or at this point use body filler (like bondo's gap filler) to smooth it out. I dont like to use filler on the larger cuts like the first pic above because it will tend to crack. using styrene is super strong. use bondo/squadron filler only for the small scratches. In the end the red is all the [bondo] putty filler I needed:  | |

| |  |

| | #7 |

| Quarry Creeper Join Date: Nov 2006 Location: Manchester

Posts: 249

|

For filling holes (like ones intended for body posts etc), I drill them out to 1/4" and glue a piece of 1/4" rod into the hole, leaving a bit of excess on the top side so I can file it smooth after the cement cures. Turns out perfect every time.

|

| |  |

| | #8 |

| Pebble Pounder Join Date: Oct 2008 Location: The sticks

Posts: 115

| Good idea i wish i would have thought of that before i did mine.

|

| |  |

|

| |