| | #1 |

| Newbie Join Date: Aug 2008 Location: Marietta

Posts: 30

|

I stretched the body out to 12.5" and now my steering is wierd. when i turns it looks like its having a hard time turning, i went out and got some allthread and made the steering rod longer but it doesnt seem to make a difference. the servo is in the original spot, i dont know whats going on. what should i do?

|

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Jan 2008 Location: fair oaks nor-cal

Posts: 340

|

maybe the angle of your axle play with your upper links

|

| |  |

| | #3 |

| Just jump it!  Join Date: Aug 2008 Location: Cedar City, Utah

Posts: 1,947

|

If you leave the servo in the stock spot you would need to get all plastic parts switched out to metal/ aluminum and get a high torque servo with metal gears. That helped mine But its cheaper to mount it( the servo) on the front axle. You can download a template from this site and make your own. I would post pics of mine but i wont be home for 3 weeks.

|

| |  |

| | #4 |

| Rock Stacker Join Date: Jan 2008 Location: Clay, Alabama

Posts: 74

|

Moving the servo is a great first step. You might find this interesting: RcGuy Servo mount question?? |

| |  |

| | #5 |

| RCC Addict Join Date: Oct 2007 Location: gervais

Posts: 1,715

|

have you locked the diffs? cuz thats one great reason why the steering sucks

|

| |  |

| | #6 |

| Newbie Join Date: Aug 2008 Location: Marietta

Posts: 30

|

yeah i locked the diffs

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Apr 2007 Location: Northern PA where the rocks grow wild

Posts: 418

|

Your best bet is to relocate the servo to the axle. Like said before, there is a free template to follow to make your own. You can use some scrap sheetmetal, or some fairly thick alum. Just be careful with the alum.... it is still pretty soft. But once you relocate the servo, and possibley upgrade to a hi-torque servo, you will be pleased with steering performance. As far as the diffs being locked, that doesn't really affect the steering in these little trucks that much. The problem your having is that you still have the stock servo, and the stock plastic steering linkage. Upgrade it and you will be alot happier with it.  |

| |  |

| | #8 | |

| Rock Crawler Join Date: Apr 2007 Location: St. John's

Posts: 548

| Quote:

Just my 2 cents. | |

| |  |

| | #9 |

| Nope..  Join Date: Aug 2005 Location: Whiteland, Indiana

Posts: 1,849

| I think the diffs being locked has some to do with it, but it's not the cause here. To be blunt, you have a shitty servo trying to push through a bunch of sloppy rods, to turn tires 3X bigger than it can. Move the servo, upgrade the servo and you'll be a happy boy.

|

| |  |

| | #10 |

| RCC Addict  Join Date: Jul 2008 Location: Fox Valley WI

Posts: 1,691

|

I like the idea of the servo up high and out of the way, especially for mud/water reasons but it's hard to get decent steering that way. A weak servo, sloppy links and a servo saver that gives too much make it tough. Mounting the servo to the axle gives the best performance, but it takes away from the looks of a clean front axle (IMO). It seems as though the longer the links the more grunt you need to turn the wheels. Geometry plays a big part in how it steers with a remotely located servo. I have a few more things to try on my basher before I give up and do an axle mount. T.D. |

| |  |

| | #11 | |

| Rock Stacker Join Date: Jan 2008 Location: Clay, Alabama

Posts: 74

| Quote:

| |

| |  |

| | #12 |

| Quarry Creeper Join Date: Apr 2007 Location: Northern PA where the rocks grow wild

Posts: 418

| My first one I made from the thick stuff (it wasn't 1/8") from the LHS that came in a 4"x8" sheet,and it ended up coming apart on me. So you got the good stuff, I bought the cheap $hit......

|

| |  |

| | #13 |

| Rock Crawler Join Date: Apr 2007 Location: St. John's

Posts: 548

|

Yeah, I went to local metal fab shop and asked for some scrap. The guy gave me a 16" square sheet and when we got to the cash he looked around and said it was free but he just couldn't say that in front of the other employees. Nothin' better than free, good stuff   |

| |  |

| | #14 | |

| Newbie Join Date: Feb 2008 Location: Iceland

Posts: 17

| Quote:

Yours Spot(T) | |

| |  |

| | #15 |

| Rock Crawler Join Date: Sep 2007 Location: Denmark

Posts: 904

| Quote:   I made a tube top for my Midgard ProPock after work today |

| |  |

| | #16 |

| Rock Stacker Join Date: Jan 2008 Location: Clay, Alabama

Posts: 74

|

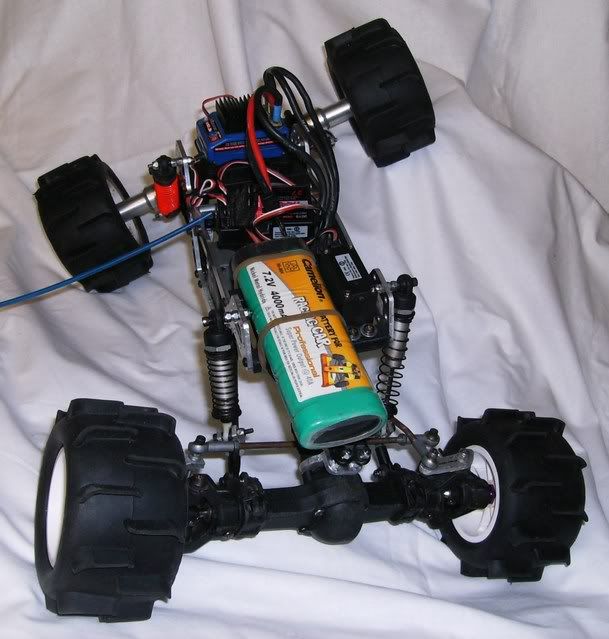

Looks good, Snoop. Maybe you can send some more pix of the front end linkage and servo mounting scheme. |

| |  |

| | #17 |

| Rock Crawler Join Date: Sep 2007 Location: Denmark

Posts: 904

| Your wish ..... My command    Last edited by SnoopMaxx; 08-30-2008 at 02:26 PM. |

| |  |

| | #18 | ||

| Quarry Creeper Join Date: Apr 2007 Location: Northern PA where the rocks grow wild

Posts: 418

| Quote:

Quote:

I think I know what a Wheely King is........ I have seen a few of them on here and a couple pictures of them in a few magazines. Thank you Mr. Spot (T) for making things simple for a dumb-ass like me to understand. If you actually READ my previous post, and try to practice your reading/comprehension skills, you will see what I was saying. It does affect the turning radius on a little truck, but not near as much as it does on a real car. Your truck might hardly turn at all, but after locking mine, it still turned damn near within the same radius as before I locked the diff. Are you sure you put your axle C's and knuckles back on the right way? I know you can actually swap sides with them and they are not the exact same. If you got em mixed up, you will know it, because the knuckle arms will sit a little bit higher or a little bit lower in relation to the axle stubs. If they are sitting higher, this causes the tire to lift up while turning, and if they are angled down, this causes the tire to push down while turning. I know this because I too have had problems with steering on both of WK rigs, and I realized it was a stupid mistake on my part. So if your having that much trouble turning, check your angles on your steering arms. | ||

| |  |

| | #19 |

| Rock Crawler Join Date: Apr 2007 Location: St. John's

Posts: 548

|

For what its worth, yes the steering is affected (only slightly) by locking the diffs but really only on hard smoooth surfaces - like floors and asphalt. You're not going to notice the difference on gravel or while crawling over rough and uneven surface such as rocks, boulders logs etc etc. To try to crawl without locked diffs is just silly. The tradeoff of a somewhat reduced steering radius is far offset by the incredibile increase in traction. It's really a no-brainer. Also, just add 4WS and, even with all diffs locked, your radius is literally cut in half. Even with the weak stock servo and the diffs locked, you should be able to turn the wheels WHILE AT SPEED. Correct me if I'm wrong but I think you really need the higher torque on your steering when either you are going very slow and need to steer OR your are stopped/wedged in and need to move your wheels for the next move. Again, I stand to be corrected. |

| |  |

| | #20 |

| Newbie Join Date: Sep 2008 Location: grimsby

Posts: 21

|

the reason for the plastic is A its cheap and B its resilient to rough driving. mines all stock as for steering, ive locked the difs stretched the wheelbase and tires and all, and on the carpet the steering sucks obviously but on my back yard crawler course its fine. it doesnt turn the wheels full turn while stopped but thats just something i compensate for. my course consists of all kinds of terrain and some times tires get caught in holes or crevices and the flex of the plastic links save my parts on the truck when either i try to drive out or pull it out. obviously if your competing youd have it axle mount and all aluminum but people competing have the money to spend on new parts. in my opinion if your backyard crawling just run with the cheapest possible and the most flexable. if youve got the cheaper parts and can crawl better then your buddy with all the hop ups its just that much better.

|

| |  |

|

| |