| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

Im lookling for advise on where to start building a tuber. Or more so, how to start building a tuber. I have an idea at to what I want it to look like and what to build out of what material. Im feeling brass tubing from LHS and making a composite frame. I have inspiration from a now discontinued bike maker company called Merlin bikes. the Merlin Cielo used titanium lugs and carbon fiber tubing for riding glory and I feel it in my heart that my crawler inspire me the way thier bike inspires me to cut, bend, smoke, burn, my fingers and my moneyl Se shall see what my brain spills out into this world. Any advise on where to start? Im thinking brass tubing tub with carbon fiber spars and braces. Obviously Im going to have to get a tubing bender and a plan book. Fire, brass stock, flux,flles, and a place to make a mess. any advise from anyone who has done this before woulb be helpful. Last edited by Elastokinematic; 07-08-2011 at 09:12 AM. |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Feb 2007 Location: South FL

Posts: 3,349

|

it might be better to mock it up in styrene first. its cheap and much easier to work with, yet strong enough for a micro to run with so long as its properly built. this way you can easily try it out on the rocks and make changes before you go to brass. you may even decide to keep the styrene because of the lower weight. this badboy is styrene New Build - Micro Rock Racer  |

| |  |

| | #3 |

| Pebble Pounder Join Date: Jan 2010 Location: Sacramento

Posts: 99

|

Here are two more great tubers. Big Block Campbell Tuber with DIG...when's it gunna stop?  Rubi tuber (update on build 9-15-11)  If you are looking for cheap metal to practice shaping try coat hangers. Last edited by bouncingbabyboy; 05-20-2011 at 10:28 PM. |

| |  |

| | #4 |

| I wanna be Dave Join Date: Feb 2007 Location: South FL

Posts: 3,349

|

the link to the coat hanger build thread isnt working

|

| |  |

| | #5 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

I have seen those except for the second red one. OK... Im gonna do it. FOR SHITS AND GIGGLES, BITCHES AND THE GLORY!!! Im off like a herd of turtles!  |

| |  |

| | #6 |

| Pebble Pounder Join Date: May 2010 Location: Indianapolis

Posts: 149

|

Those tubers are badass!!!!   That's some great work there. |

| |  |

| | #7 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

that post with the Rubicon body is really helpful. Great pics. TY  . I guess ill head to LHS and see if tubing is crazy expensive. If so, Ill internet shop it. TY all. When I get started Ill post up. . I guess ill head to LHS and see if tubing is crazy expensive. If so, Ill internet shop it. TY all. When I get started Ill post up.

|

| |  |

| | #8 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

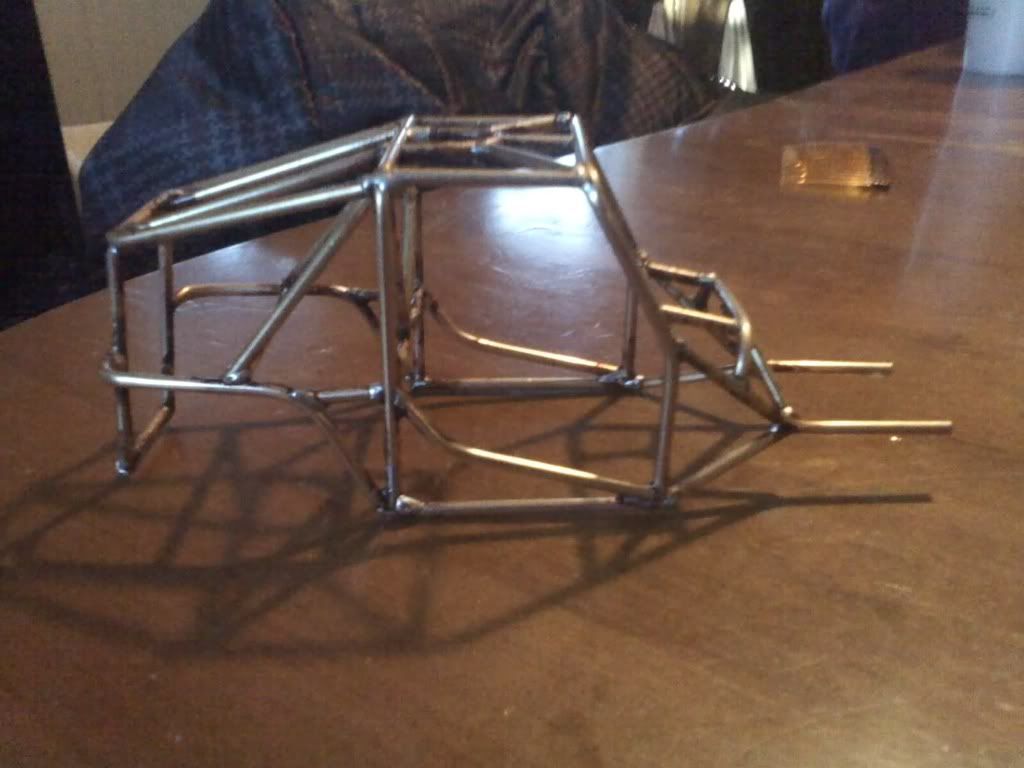

well heres attempt number one. Alot of time looking for tubers on the net and on RCC gave me plenty of ideas. This was just a study on how to work with and bond styrene. Im just going to stop this one because the cantilever suspension is too stiff for my liking. I got the ratios all wrong and I didnt spend enough time making sure that everything was squared up. I started this attempt with 3/8 tubing. It was very thin walled and it was pissing me off because I couldnt figure out how to heat and bend it without deforming it. I tried sand and table salt and I couldnt get it right. Turns out that the tubing I was using was very thin wall and I had just set myself up for failure. So I bought some 1/8 styrene rod. MUCH BETTER! If you are going to try this use plastic solvent cement to glue parts together. Alot better than CA glue. Dont stick to the fingers!! Attempt two already boiling in my brain. My girlfriend and I sold my couch in the second bedroom here and she is HIGHLY recommending I get a work table to work on my little cars. Her father was big time into model train sets and had a complete room set up with the full blown towns and little people and shit. She says that anything less than that aint that bad. Gotta love a girl like that! Heres pics of attempt #1. pics are a bit fuzzy. Iphone cam is not the best in the world... I made everything there minus the springs. hinges, lugs, it was fun... I learned alot on this one. Im kinda proud of the cantilever setup. Its not the best attempt but it looks cool and it works. As you can tell I started on the front and worked back and down. I got better as I went. Last edited by Elastokinematic; 06-05-2011 at 11:17 AM. |

| |  |

| | #9 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

Wow! I guess from the lack of comments I need to do a better job on the next try...

|

| |  |

| | #10 |

| I wanna be Dave Join Date: Feb 2007 Location: South FL

Posts: 3,349

|

I posted a comment, i guess it didnt go through. I said something like you suck and should leave this forum and never come back........ Jk  Great job so far  . I look forward to version 2 and seeing video of the cantilever suspension in action . I look forward to version 2 and seeing video of the cantilever suspension in actionBTW the GF is a keeper for sure haha |

| |  |

| | #11 |

| Rock Stacker Join Date: Jan 2009 Location: glengardener

Posts: 65

|

Great work so far man and styrene is tricky to get to bend rite but what I do is bend it around a coin of the correct diameter bend I need and run a lighter past it to let it get soft and form around the coin than I hold it a few seconds it cools and perfect bend but warning styrene heats up fast u need the lighter There no more than split second here is link my build thread on a different form hope it helps yah http://www.scale4x4rc.org/forums/showthread.php?t=59131 |

| |  |

| | #12 | |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

| Quote:

| |

| |  |

| | #13 |

| Rock Stacker Join Date: Jan 2009 Location: glengardener

Posts: 65

| They work good for brass and other metal bug styrene cracks if u use a bender that's y I bend it slowly around coin heat it up to hold it's shape I say my chassis came out pretty good for not using a brake tubing bender

|

| |  |

| | #14 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

thats awesome work! hows the thing crawl? Im getting used to working with the styrene. I just purchased a bunch of tools yesterday at LHS to get geared up for attempt number 2. when I get used to making tubers I think Im going to try brass. Im having fun with this. Thanks for the replys. feedback wanted. tips needed. |

| |  |

| | #15 | |

| Rock Stacker Join Date: Jan 2009 Location: glengardener

Posts: 65

| Quote:

But anyways need help just shoot me a message | |

| |  |

| | #16 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

tyvm.  |

| |  |

| | #17 |

| Rock Stacker Join Date: Jan 2009 Location: glengardener

Posts: 65

| No problem man here few my past tuber attempts     that is my brass attempt was going well til it fell and was sqaushed by foot and the cj7 tuber just got old not so scale to me so I started the rubi tuber and I'm making it as scale as possible and hiding all emeralds with full interior hope these help u lil brass is tricky and I use a pen torch for brass good luck man can't wait see ur 2nd attempt that is my brass attempt was going well til it fell and was sqaushed by foot and the cj7 tuber just got old not so scale to me so I started the rubi tuber and I'm making it as scale as possible and hiding all emeralds with full interior hope these help u lil brass is tricky and I use a pen torch for brass good luck man can't wait see ur 2nd attempt

|

| |  |

| | #18 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

second attempt in progress. I have horded all .125 styrene rod from the 3 LHS in the area. LOL! Tube is too much of a bitch to bend and keep from kinking. Im using a heat gun and a cordless soldering iron with heat gun attachment for fine detail. Im finding that bending the smaller pieces earns me burnt fingers! Thats a really nice tuber!  I think im going to build a few more styrene ones just to get the hang of building chassis and getting the scale right. I bought some brass rod and tube and flux and silver solder at Home Depot and tried to stick em together. I wasnt satisfied with the result. Ill keep trying. I think im going to build a few more styrene ones just to get the hang of building chassis and getting the scale right. I bought some brass rod and tube and flux and silver solder at Home Depot and tried to stick em together. I wasnt satisfied with the result. Ill keep trying. Thanks for the pics, ideas, and advise. second attempt pics coming. |

| |  |

| | #19 |

| Quarry Creeper  Join Date: Apr 2011 Location: Dallas

Posts: 288

|

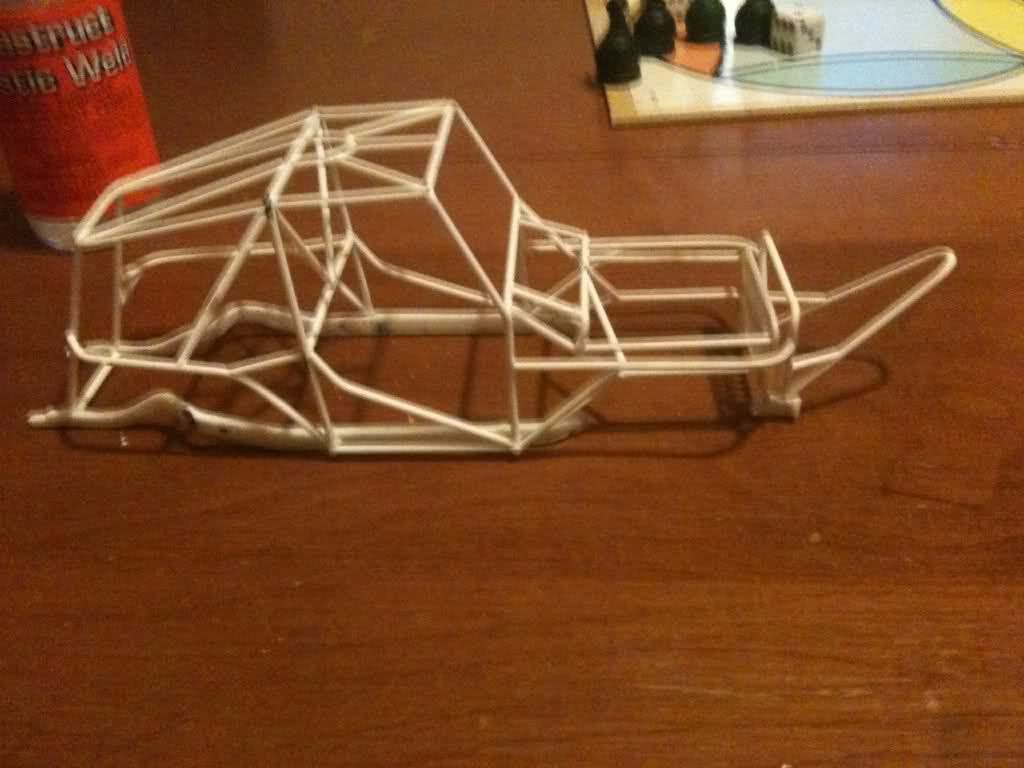

studies in styrene continue. this one is pretty square and Im happy with the result. it looks good but in my excitement I didnt leave room for rear axle and the steering servo. oops. im on the fence of whether or not to hack this chassis up and work around it or make another. heres pics of tuber attempt #2: |

| |  |

| | #20 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Nice Man! The only way to get it done or figure it out is to jump in the fire. May I suggest searching pirate4x4.com under KOH buggies or cars and find even more inspiration.

|

| |  |

|

| |