| | #1 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

I want to see everyones BTA and dig pix. up close and show me your clearences please.

|

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Oct 2009 Location: In the mancave...

Posts: 1,038

|

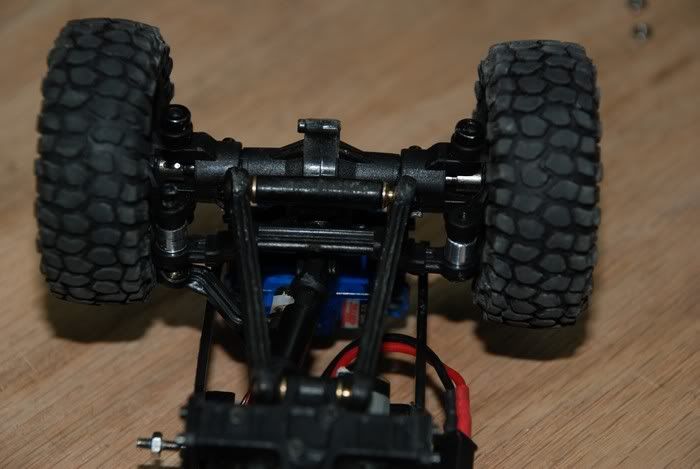

NO! ahh, just kiding...here's my post from my clubs website..... no DIG tho... So although i've been busy with the new house and all, i did find some time to do some work on the micro. The first thing was the chassis. i swapped out the stock chassis for the DP Torsion chassis. At first i was not very impressed. After some research i found that the wheels need some weight in them. ( then again, dont they all? ;) ) so i asked my buddy for some lead shot. he gave me #6 and #8 lead shot. (i know nothing about guns, except that i will hurt my self with one) i threw 60 grams up front (30 grams in each wheel) and 40 grams in the rear (20 in each wheel). wow, what a difference. this brought out the full potential of the chassis! it has WAY more articulation than the stock setup. the lead shot was loaded into the new tires i bought. i grabbed two sets of RC4WD's Rock Crusher's from ebay for $14 shipped. i mounted these on the stock rims without the rings. (i'm sick of'em!) now, with the shocks removed, guess what??? BTA is now possible! so, using stock parts, i switched the knuckles from left to right (so the ears are facing the rear), and reversed to steering link. i spun some 3/16" long spacers and tapped them with a M2x.4 tap. mounted everything up and it works without a flaw. so all in all, the chassis and the tires are a HUGE improvement. the tires not only look a lot better but out perform the stockers ten fold. The torsion chassis is just great. it lowers the overall ride height and flexes much better AND more consistently than the stock one. and the BTA opens up new lines. anyway here's some pics...... The Lead Shot (this was for one rear tire)  Side to Side Comparison of old tire vs. new (before BTA)   DP Torsion Chassis mounted  BTA (2nd pic shows the spacers i spun)   And some action shots (looks so clean w/ the BTA)    |

| |  |

| | #3 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

Thank you very much for the pix. I just got a torsion chassis and love the way it crawls not much flex right now I have 40 bbs per front tire and 30 bbs per rear and it still has little flex. Do the torsion arms need to be broken in?

|

| |  |

| | #4 |

| Rock Stacker Join Date: Aug 2010 Location: Montreal

Posts: 51

|

You can really improve articulation by running the "loose" set-up where you only screw in the torsion link screws about 3 turns.  I also boil annealed my chassis. There are more details in the "pilmat Build Log" thread. Cheers, Phil. |

| |  |

| | #5 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

Right on, I'm only 3 turns out. I have one issue with the stock parts BTA I lowered my body about 3/8 of an inch or more and the servo hits the body with the servo sitting up higher, so now I have to make custom links for the BTA. Anyone got some pix of custom link BTA.

|

| |  |

| | #6 |

| Rock Crawler Join Date: Mar 2008 Location: Grand Rapids

Posts: 918

|

the gap below the servo looks like a nice place for the esc reciever or some weights IMO

|

| |  |

| | #7 |

| Rock Crawler Join Date: Mar 2008 Location: Grand Rapids

Posts: 918

|

Jeepkid these things are so small you could prob get away with the ziptie drag link mod and maybe do the same for the steering link too just heat it and twist it 90 degrees maybe run the servo low and flip the horn mine is still a couple weeks out if you dont have it figured out by then ill just make 2 sets of what i do

|

| |  |

| | #8 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

I really like threaded rod idea cuz youwant a good amount of wieght in the tires and I bet the wieght would bend and deflect the zip ties. And zip tie are just a way of having an unclean looking setup.

|

| |  |

| | #9 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

Is that hitec 55 smaller then the stock servo.

|

| |  |

| | #10 |

| RCC Addict Join Date: Oct 2009 Location: In the mancave...

Posts: 1,038

| |

| |  |

| | #11 |

| I wanna be Dave Join Date: Jan 2008 Location: GrandRapids, MILITIAGAN

Posts: 3,197

|

Thanks rik you have been a great help

|

| |  |

|

| |