| | #1 |

| Rock Stacker Join Date: Feb 2010 Location: Portland,OR

Posts: 93

|

Has anyone seen these makerbot 3d printers (http://www.makerbot.com/) i stumbled into them the other day and could only think of all the little rock crawler parts i wanted to print out.

|

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Jan 2009 Location: Brampton, Ontario

Posts: 42

|

Pretty cool. Suprised it hasn't been done before. F-ing expensive though. Better off paying someone to fab you a part.

Last edited by IRON MAN; 06-11-2011 at 05:53 AM. |

| |  |

| | #3 |

| Newbie Join Date: Nov 2010 Location: Australia

Posts: 14

|

It's only expensive if you don't make anything to sell....

|

| |  |

| | #4 |

| I wanna be Dave Join Date: May 2006 Location: akron

Posts: 4,054

| |

| |  |

| | #5 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

We've used the Solido SD300 printer to prototype parts. A great tool to prove out overall fit before going into production with parts. http://www.solido3d.com/default.htm |

| |  |

| | #6 |

| Newbie Join Date: Jan 2009 Location: Brampton, Ontario

Posts: 42

|

The original post was for parts he wanted for himself. Not for him to make parts to sell. At $1300 for the regular kit and $2500 for the custom kit, I still think its expensive for personal use, especially for a McRC. If he plans on using it to fab parts for himself and sell to others, then sure it'll be worth it. |

| |  |

| | #7 |

| Pebble Pounder Join Date: Apr 2010 Location: Brighton, MI

Posts: 175

|

I use rapid proto parts at work alot. They are cool, but the surface finish is less than desirable and the strength is not the same as a machined or injection molded part. Great to test fit or even test run, but not meant for production.

|

| |  |

| | #8 |

| Pebble Pounder Join Date: Mar 2011 Location: Calgary, Alberta

Posts: 137

|

i have used simular and it is so convenient for prototyping a part put it is not that strong. mostly good for testing the fit.

|

| |  |

| | #9 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Pretty much looks likes sculpted shit, and probably just as structural. My $.02!  |

| |  |

| | #10 |

| Newbie Join Date: Nov 2011 Location: Richmond, IN

Posts: 11

|

hello, so the makerbot parts are not as strong as delrin parts ? its a cool machine. I'd just like to make my own chassis's since I can't find a bodyiless one in stock any where.  |

| |  |

| | #11 |

| RCC Addict Join Date: Mar 2010 Location: Auburn, MI

Posts: 1,177

|

I ran across this the other day. Autodesk 123D - Free 3D Modeling Software, 3D Models, DIY Projects, Personal Fabrication Tools New deal from Autodesk, the guys that make AutoCAD, you down load their software, do the design, and then send them the files to rapid prototype.. Great idea, just concerned about the strength of the parts for crawling, etc.. For me, I want to cut steel and aluminum, so I am working on buying a table top mill, and a lathe in the future, so I can CNC parts straight from billet, or maybe even some rough castings.. |

| |  |

| | #12 |

| Newbie Join Date: Oct 2011 Location: Coon Rapids

Posts: 31

|

Just incase anyone is interested in DIY 3d printing, this is probably the BEST place to start: www.reprap.org But as far as affordability goes, this bad boy just showed up: $500 printrbot - Home |

| |  |

| | #13 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

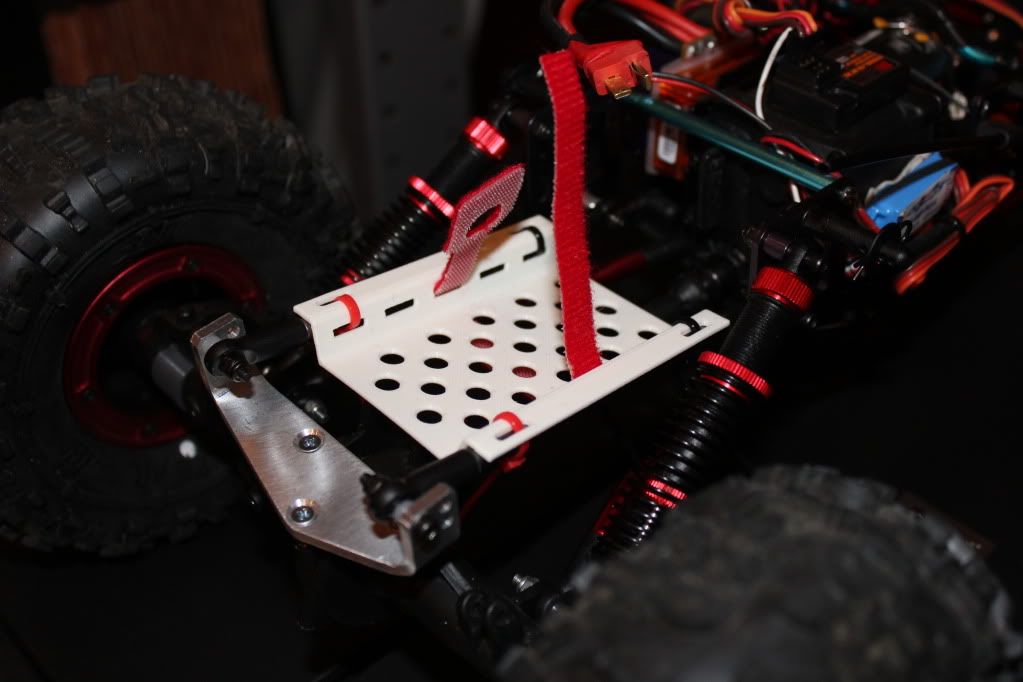

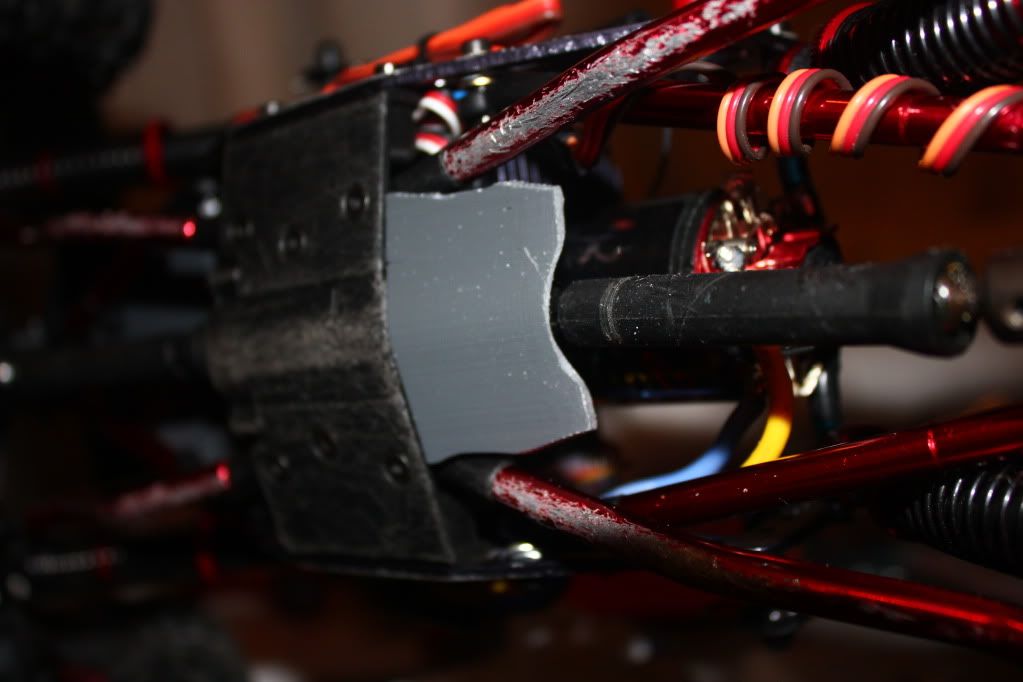

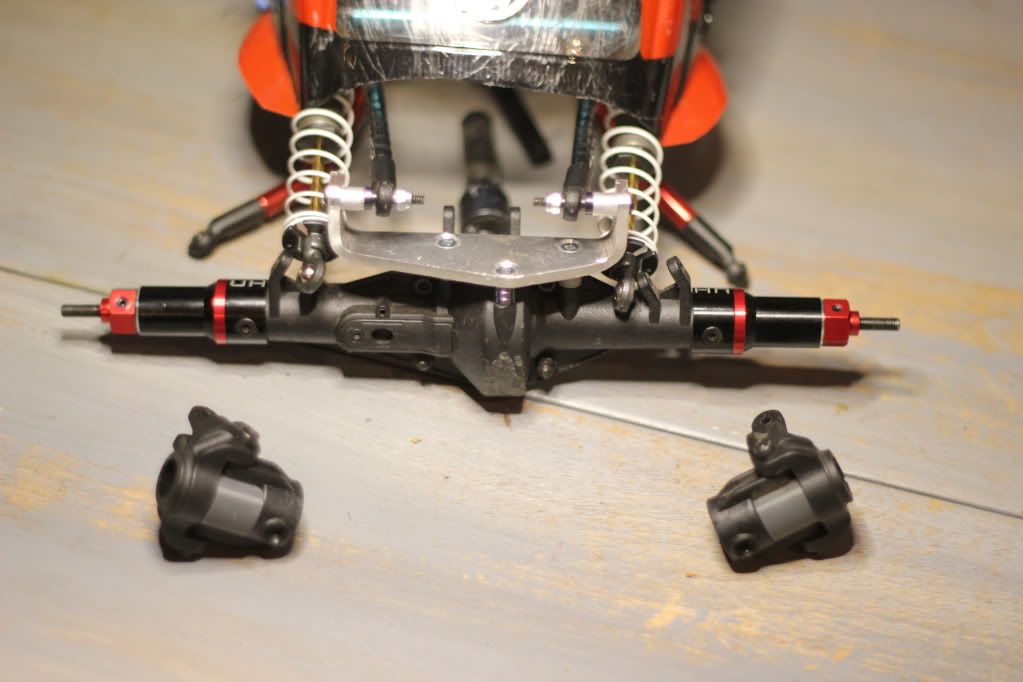

I use a stratasys uprint 3d printer to prototype parts sometimes. It's pretty great. The Makerbot uses the same material and is almost the same resolution. The one I use is a lot easier to setup the prints but thats what you get if you pay an extra $30000 The Maker bot and other fdm printers lay out lines of melted abs like a high res glue gun. It is pretty weak because it can tear between layers of the material. I've made some stuff you can see in my creeper build thread.     Delrin is WAY stronger. If you have access to cad you can also send a file to a company like shapeways.com They can make your part in steel! (of course, it is weaker than normal steel. Kinda like how the abs prints are weaker than an injection molded abs piece.) This place uses a different type of printer. Moddler |

| |  |

| | #14 |

| Pebble Pounder Join Date: Dec 2010 Location: Jackson, Michigan

Posts: 136

|

so make your part, test it, and if it works cast it in resin. Its a little heavy and harder but id imagine for smalle scale stuff, making knuckles and what not would help lower cg. I dunno the process for injecting plastic, as when we do a mold at home its with silicone molds.

|

| |  |

| | #15 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

That type of printing is really just to prove a concept. We have one at work, and it's more than paid for itself, but the parts really aren't strong enough to last long. Shouldn't this be in Tools and Procedures? |

| |  |

|

| |