| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

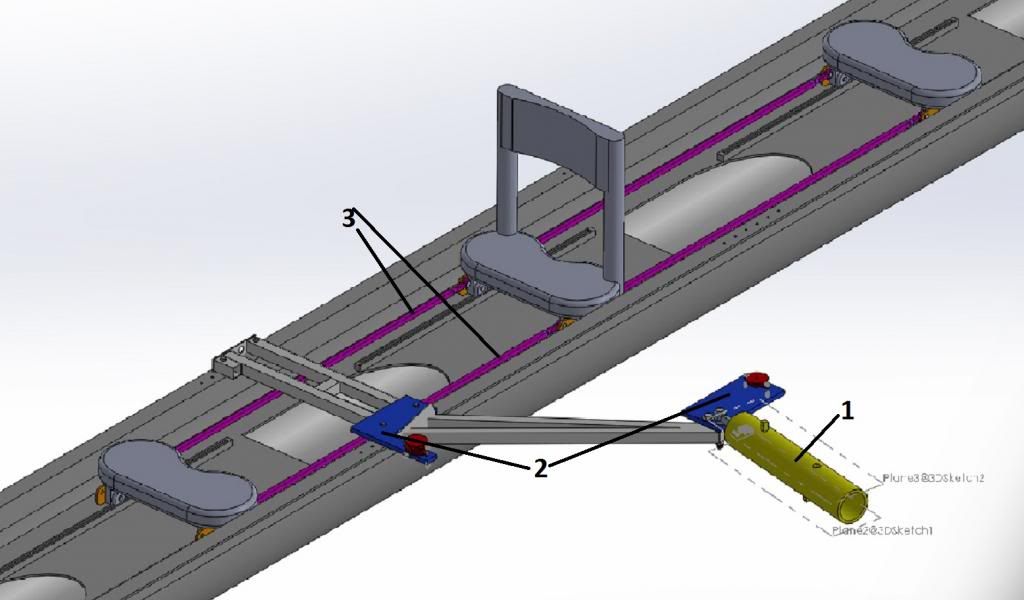

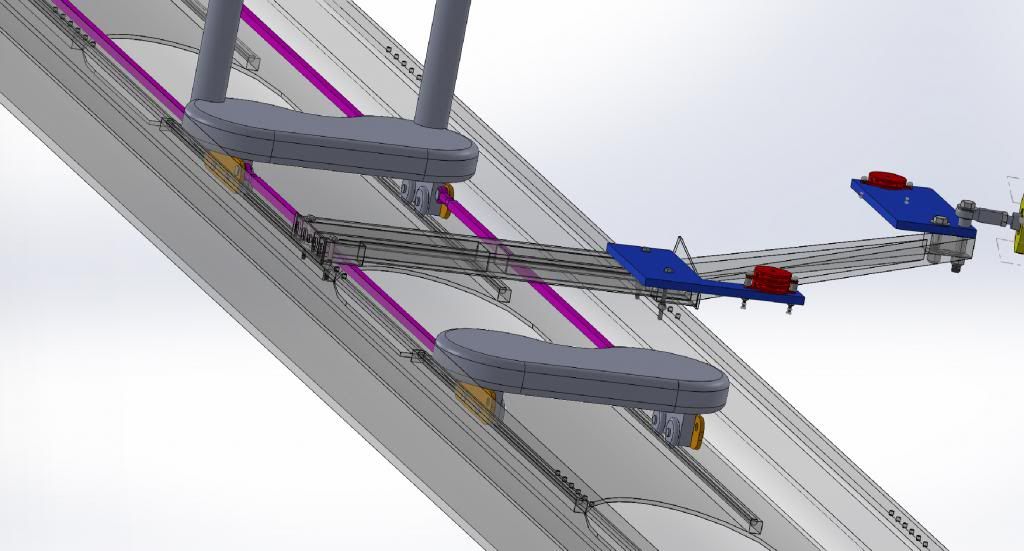

Here is the beginning of an idea I have been thinking about. The parts will mate up to standard 1/8" hollow tubing with either 1/4" long stainless steel dowels, or the correct OD of copper wire. Inside diameter is .0625" This is just a start, there will be many more components. Theoretically all one would have to do is cut accurate lengths of tubing and press-fit, then glue the parts together. These parts are simple to draw which is perfect for me as I am still learning SolidWorks. Feedback is welcome!  |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: May 2011 Location: Bama!

Posts: 514

|

How much is the solid works program ? I think it would be to to design our own stuff and have you print them for us.

Last edited by smuggl1n; 01-30-2013 at 10:26 AM. |

| |  |

| | #3 |

| Newbie Join Date: Oct 2012 Location: McHenry

Posts: 15

|

That's what Shapeways - Make & Share Your Products with 3D Printing is for  Looks great Jim! Definitely something for the tinkerer at heart |

| |  |

| | #4 |

| Rock Crawler Join Date: Oct 2011 Location: Lexington

Posts: 503

|

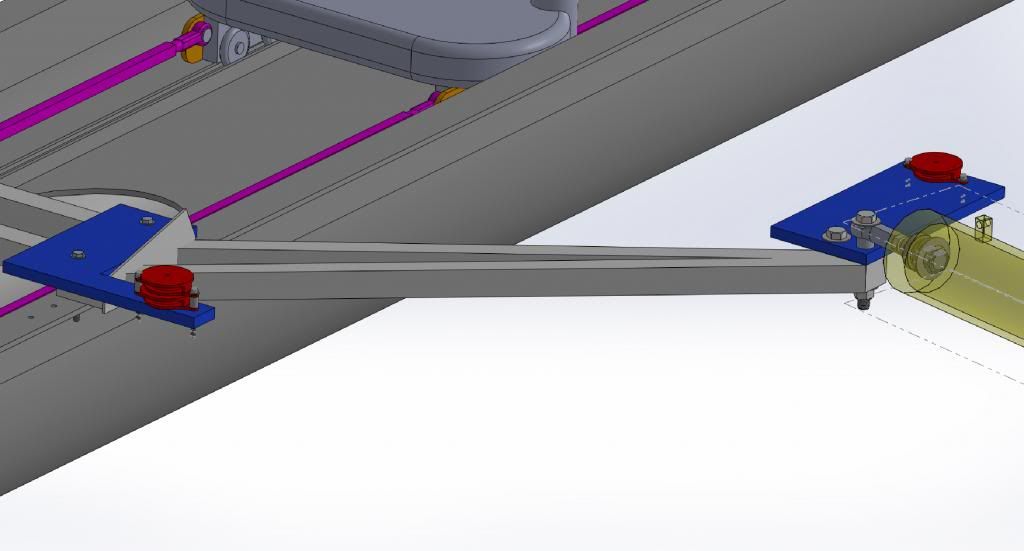

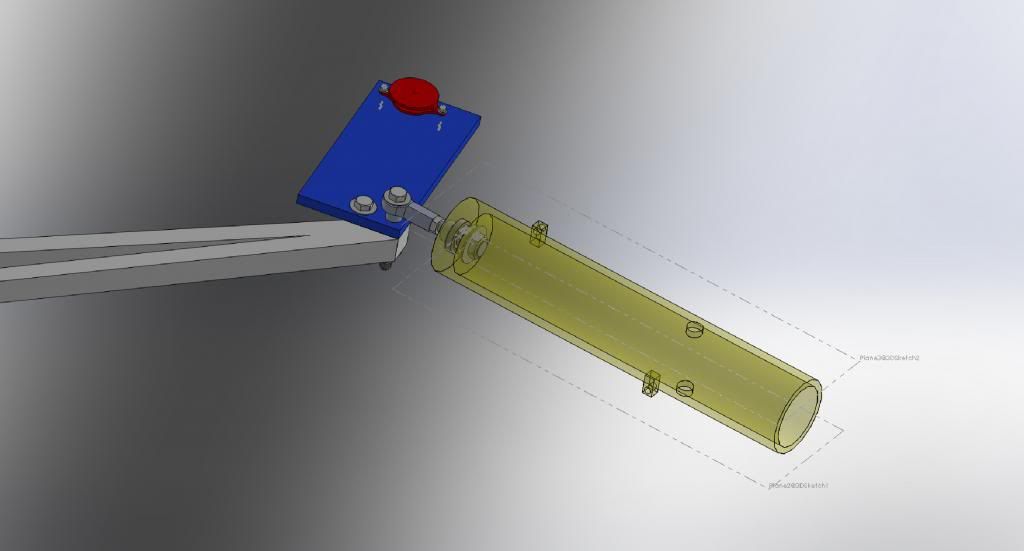

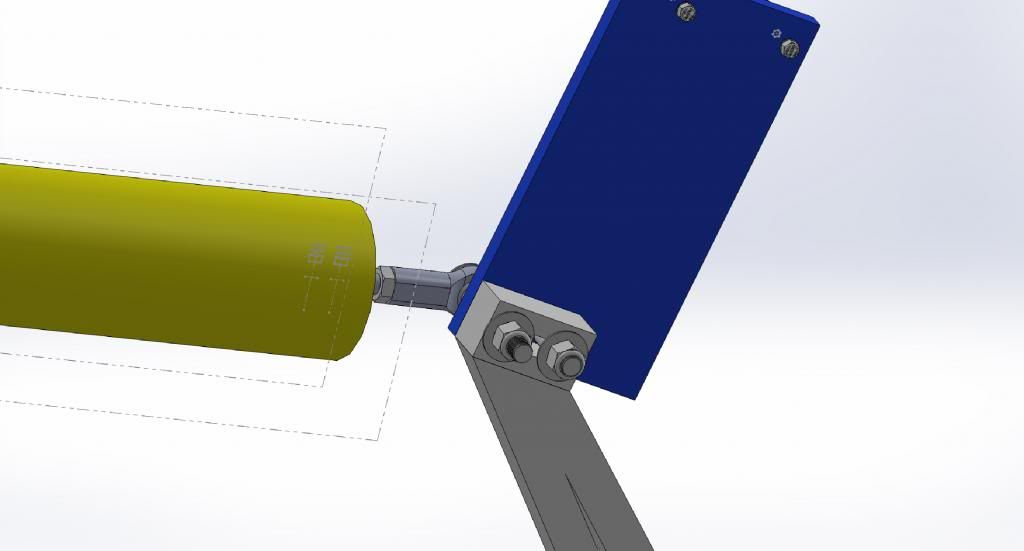

Solidworks is pretty expensive. A 1 year student subscription is $87. After a year it stops working and you have to renew. Ouch! While I like the idea, I think you will see a number of problems with these parts. Chief among which is how are you going to make them? You're talking about some insanely small stuff here (those bolt holes will most likely be too small for even the M1 bolts or whatever it is Losi uses on the EP tray and skidplate). If you use a 3D printer, you are going to have to do some serious quality control (to clear out the casting flash), and a mill is pretty impractical. To give people an idea of the scale, the I.D.s of the holes here are 1/2". The final parts will be 1/4 the size of what you're seeing. If you're serious about making these, I wouldn't go with a press fit. The tolerances will have to be super tight and that will drive your costs up (a press fit needs to be exact down to 0.005" and the rods people will be using will almost certainly not be within that spec). Force a rod or wire in too hard and it'll snap and now you've lost a joint. You're better off making the I.D. a bit large and having people glue their rods in. I've played a lot with SolidWorks and one thing a lot of people screw up is the transition from CAD to reality. Parts and pieces may look beautiful and perfect on the computer screen, but make them for real and your problems pop up. So while I think the idea is great, I'm not sure it will translate too well to reality. It's happened to me more than once and it's happened to a lot of my classmates. For example, here was my Junior Design project:  (In case you're wondering what you're looking at, this is supposed to be an adaptive rowing system for quadriplegic patients who want to row crew shells. If you all want more info, I'll start a new thread.)    (Yes, I am completely showing off right now. This was my entire Thanksgiving break and then some this year!)  Looks awesome, the idea completely didn't work when we built a prototype. And making it work turned out to be impractical as well. I have a feeling you'll be in the same boat (no pun intended) with your tiny parts. Again, great idea (and nice sketches dude!), but I don't think reality will work quite as nicely. Sorry man. |

| |  |

| | #5 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

With all due respect I have 25 years experience with "making things" and you are way off base here. Plus you spammed up my perfectly innocent post with nonsense that has nothing with crawling or even modeling. My printer will make these parts with a much greater precision than your 5 thousandths reference, which is huge for my machine. My printer has a 16micron resolution guy. I'm not in your boat... |

| |  |

| | #6 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

The holes are not intended to hold the base brackets in place. They are held in place with a screw from the bottom. The holes are filled with painted bolt heads later.

|

| |  |

| | #7 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

Thanks for the other good comments. I paid like $5k for my SolidwWorks seat. I've paid more for less...  |

| |  |

| | #8 |

| Rock Crawler Join Date: Oct 2011 Location: Lexington

Posts: 503

|

[QUOTE=Fungi;4153561My printer will make these parts with a much greater precision than your 5 thousandths reference, which is huge for my machine. My printer has a 16micron resolution guy.[/QUOTE] Oh well in that case, please accept my sincere apologies. If you can get that kind of precision, by all means go for it! I still think gluing would be better than a press fit, unless you're planning to provide the rod too..which would be badass. An entire chassis building kit would be pretty sweet to see. |

| |  |

| | #9 |

| Quarry Creeper Join Date: Jan 2013 Location: La Verne

Posts: 338

|

I would love to have some of those goodies to build a chassis with...when can I get some and give it a go?

|

| |  |

| | #10 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

Sigh... if you read it again it says press fit, then glue... ;)

|

| |  |

| | #11 |

| Pebble Pounder Join Date: Nov 2012 Location: CO

Posts: 138

|

I really like the idea of the two with base plates those would be helpful in mounting frames to bodies! A nice base plate that can just be glued then the frame put on from there Edit: The cross over one would rock not having to try and solder an X 2nd Edit: these would be SICK for making bumpers for scalers. I'd buy a set |

| |  |

| | #12 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

Five freaking huge ass pictures of some stupid rowboat to say "things in cad don't always work in real life" are you kidding me. LOL

|

| |  |

| | #13 |

| Rock Crawler Join Date: Jan 2012 Location: Champlin, MN

Posts: 507

|

I understand the urge to spread your proud hard work. but I agree jesus there is a time and a place. and a stupid rowboat does not belong in a thread about tubing designs. Nothing makes a person seem legit like "hey it wont work because this one time I made this one thing and it didn't work. therefor by logic nothing will work."  I have zero doubt in the quality of the machine you purchased. Edit: flagged it as spam. I don't want your awesome idea squandered with spam posts. |

| |  |

| | #14 |

| Newbie Join Date: Jan 2013 Location: boston

Posts: 4

| |

| |  |

| | #15 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

| |

| |  |

| | #16 |

| Quarry Creeper Join Date: Mar 2011 Location: OrangeVale

Posts: 293

|

fungi cool idea! The applications are endless with this... Ps tell beat to delete his post it has nothing to do with crawling... |

| |  |

| | #17 |

| RCC Addict Join Date: Jan 2011 Location: Forest Floor

Posts: 1,108

|

I'm posting some images to illustrate the capabilities of my printer. The finish on the demo part is mat as it was completely covered with support material. It was printed in the lower resolution. The chassis part was printed at 3DS on a similar machine at the higher resolution. The ruler is showing mm! In one image you can see the lines are much finer than my fingerprint.                   |

| |  |

| | #18 |

| Quarry Creeper Join Date: Aug 2011 Location: Sacramento

Posts: 394

|

Have you thought of attempting press fit ball cup?

|

| |  |

| | #19 |

| Quarry Creeper Join Date: Dec 2012 Location: Pioneer, 95666

Posts: 397

|

Do you have an ETA on these? I'd be all over those parts like a fat kid on a doughnut. be a great way to start learning scale fabrication like bumpers, cages etc...

|

| |  |

|

Jim's 1/8" tubing design parts... O.o - Similar Threads

Jim's 1/8" tubing design parts... O.o - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Who is running an Evil Crawlers Design "The Ringer" | mmatthews | Axial AX-10 Scorpion | 20 | 06-08-2012 05:15 AM |

| The words most vendors don't want to hear. "I think someone copied your design". | John | Chit Chat | 52 | 12-23-2007 11:00 AM |

| Tubing for buggies, benders and "welders"? | DoM | Newbie General | 2 | 02-06-2007 11:18 PM |

| |