| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Jan 2008 Location: www.rccrawler.com

Posts: 1,113

|

I cant seem to get the sweet spot on using this thing and my front steering is minimal (over 30 degrees less than the rear which has a regular steering system). I am using an aluminum servo horn and not the suggested horn or saver that's in the Thundertech photos ... Any advice ??? Thanks !!! |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Jun 2006 Location: Wisconsin

Posts: 570

|

It would help to see some photos. What exactly is stopping you from getting more throw? Is the drag link hitting the axle case? Is the servo linkage hitting or binding up/angle just to far off for the rod ends to compensate? Usually it's a matter of fine tuning the steering geometery, and most specifically, the getting the servo linkage straight and level, at neutral, or as close as possible. Do this by adding stand offs on the servo arm, if need be, or stand offs on the drag link, where the servo linkage bolts to the drag link. You can use conical washers, bushings, nuts, washers, and other similar items to get the linkage the way you need it to be.

|

| |  |

| | #3 | |

| RCC Addict Join Date: Jan 2008 Location: www.rccrawler.com

Posts: 1,113

| Quote:

| |

| |  |

| | #4 |

| Tire&Foam Extraordinaire  Join Date: Jun 2007 Location: C.I. Compound, Tyler, Texas

Posts: 5,601

|

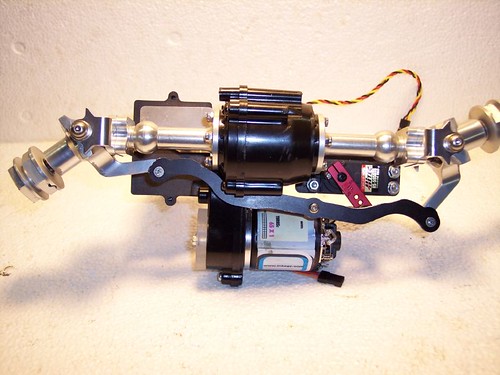

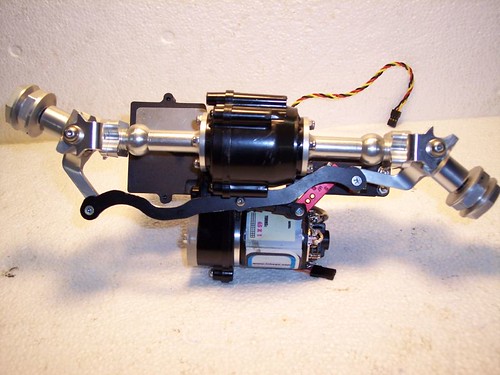

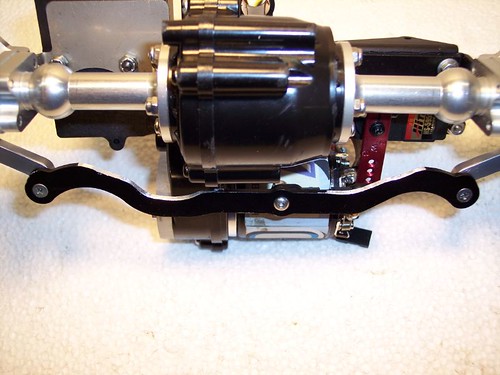

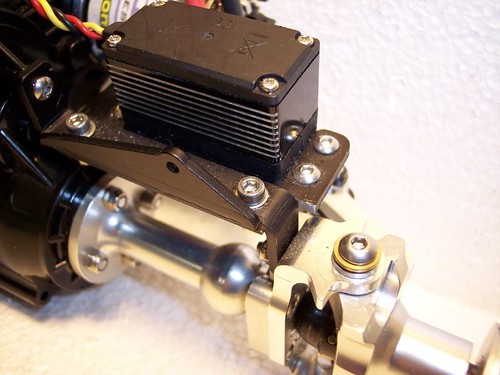

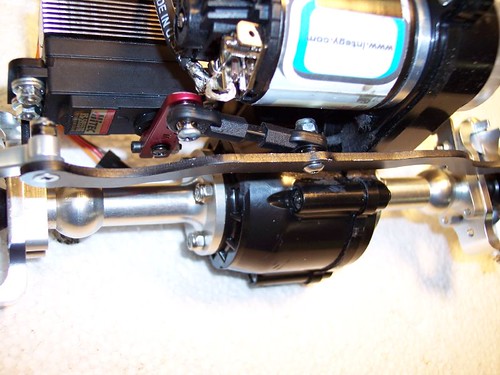

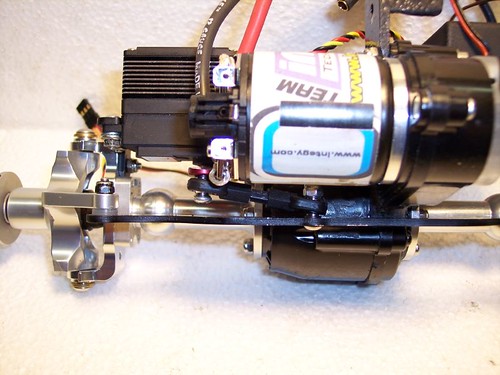

Here is what I did on my TTR BTA's. I documented this in my Super build named "Grumpy". I have since parted that super out. I did have good luck with the TTR BTA's in both my 2.2 clod build "The Grunt" and my super build. Both of those builds were using JP Customs Pimp Canes. My new Super is four linked which is why I parted out the pimp cane and TTR BTA's. Here is how I modified the steering to get maximum turning radius. Everything must have clearance so the only thing limiting steering is the TTR CVD's.   I used the same techniques for the most part that I used on "The Grunt". This photo shows how I reshaped the TTR BTA steering link:  These next three photos show the modified TTR BTA assembly. The servo plate is suppose to be installed on top of the bracket. If you cut the servo mount plate to fit below the TTR axle brace it lowers the COG slightly and positions the servo horn lower to the steering link:  Once the servo is mounted lower, you gain some clearance from the motor. I use an aluminum airplane servo horn because of the length and travel it gives me. I realize I am losing some torque, but it has not been significant on "The Grunt", so I am hopeful it will be OK on the Super. Note how the clod case has been shaved for extra clearance for the steering linkage.  With the servo lower and the longer servo horn attached, you can now make up the linkage to connect it to the steering link. With as much travel as I am getting due these mods, I have to bevel the servo horn, bevel (grind) a little on the motor, file the clod case, and file the rod end slightly on the linkage to make sure everything clears.  |

| |  |

|

| |