| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

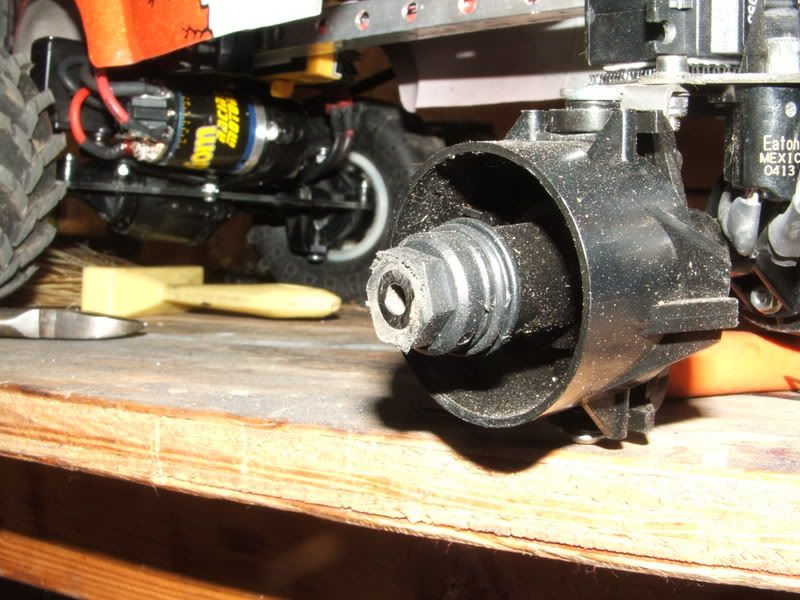

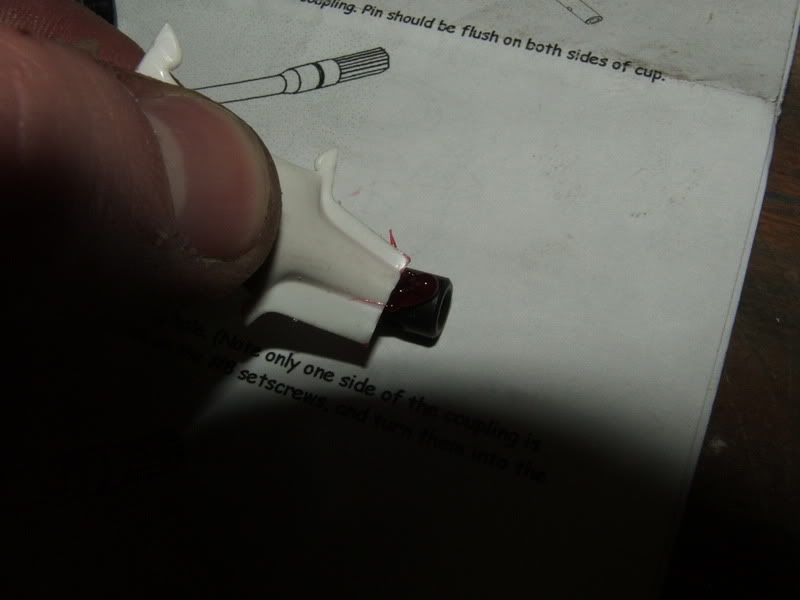

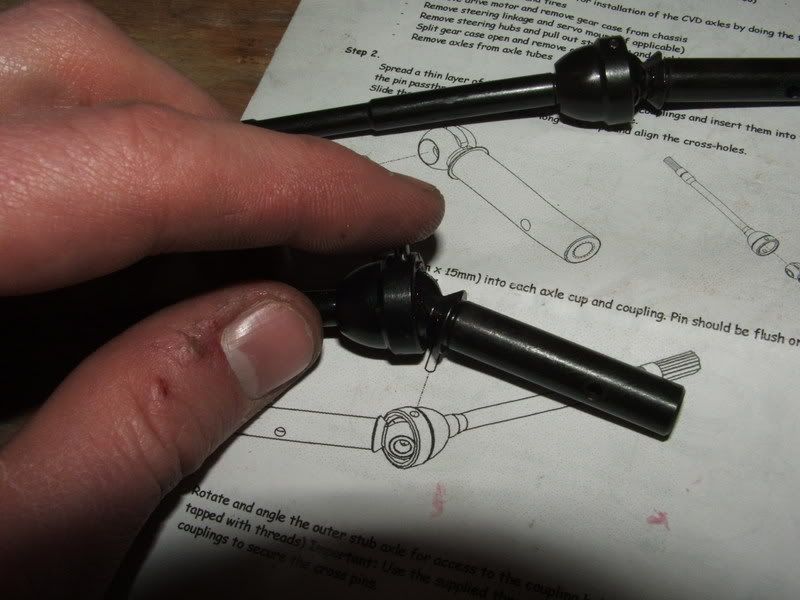

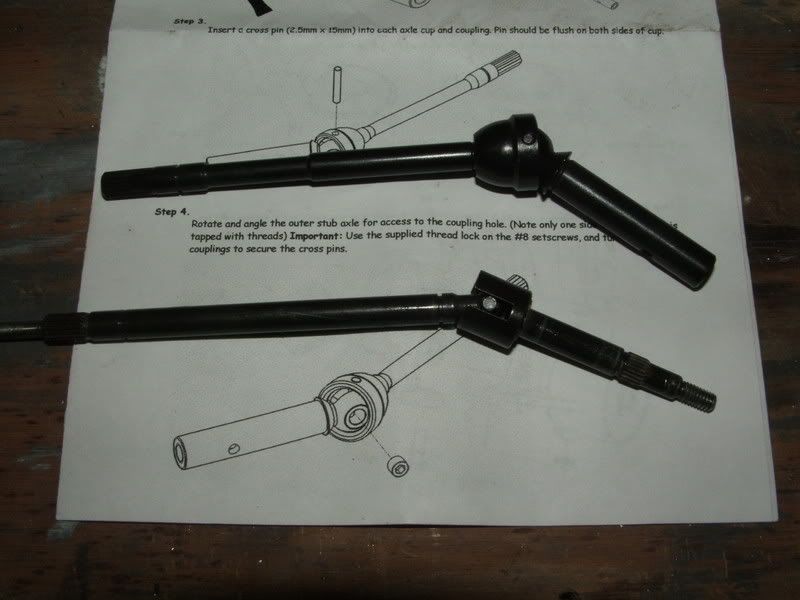

I figured with the new storm of Newbies showing up and asking questions I figured I would help out a little. For any Comp Crawler or for anyone who want the best for there rig. These are a must have for 2.2 Clods. And they should be one of the first things done. For $45 bucks for TTR's (Thundertech Racing) and $35 for Straight Axles they should be one of the first upgrades done. Now for 2.2's the strength isn't really an issue. But the CVD's turning radias is a big plus. Makes the gates alot easier to clear. They are 33% stronger and 8mm thick. BEEFY. Now for the the Straight axles. These are the same thickness. 8mm and 33% stronger. Now if you run a 2.2 in a Comp you cannot have Rear Steer. So what better way to do. Now you can save the money and rig a link up to lock out the rear. But that seems to cause Clearance issues sometimes. You can do the Washer trick. Which I did first. And it seemed to work great for about 3 months. But that added extra stress to the axles C's. Causing me to break an axle C. Many have used that method with zero issues. But from what I found out. When buying 1/2in washers. every washer had a different thickness. Even if it said it was the same. So then your looking for different washer and test fitting dozens of washers to get the right one. But thats not for me. Specially when I have tear apart my rig and tear down the axle to fix it down the road. So this time I ordered new axle tubes. And axle stiffeners along with the new TTR axles. So after all these it should be bullet proof. Here are the Benifits they list on there site for the CVD's *Stronger than stock axles (8mm outer axle) *Sharper turning potential *1/4" wider per side than stock *More efficient transfer of power MIP-CB01 Kit Includes: *1 complete pair of CVD axles *2 outer drive hexes (molded) *Four 8x12mm ball bearings *2 wheel bolts (16mm x 5mm) *2 drive pins *2 rubber o-rings (for drive pin retention) *Two 5mm E-clip rings *Two 6mm shim washers *1 center gear pin (3.5 x 20mm) *installation instructions And for the Staraight Axles: *Stronger than stock axles (8mm outer axle) *Stronger than other aftermarket straight axles *Eliminates rear steering *1/4" wider per side than stock *More efficient transfer of power MIP-CB02 Kit Includes: *1 pair of Straight axles *2 outer drive hexes (molded) *Six 8x12mm ball bearings *2 wheel bolts (16mm x 5mm) *2 drive pins *2 rubber o-rings (for drive pin retention) *Two 5mm E-clip rings *Two 6mm shim washers *1 center pin 3.5mm *installation instructions Here you can see the difference in size from the stock one to the TTR CVD's  And here you can see the turning ability you can get. The steering arm is touching the axle tube.  Here is a picture off of TTR's site on the straight axles. These pictures are of the 1st Gen ones. The new ones have Splined ends. Which are the ones that I have. I will update the pictures when I get a chance.   Now with these there is no need for locks outs. Here are few pictures of ways guys have lock the rears out in the past.     Now from what you have seen. All of these cause clearance issues. All but the washer trick. Here in this picture you can see I shaved off the steering arms. They seem to get hung up sometimes when reversing.  I believe you can order now knuckles with out steering arms. Not sure where right now. But I know I have seem them some where. Well here in the next couple of days I will finish these review and a how to on these. I just wanted to get the basics down first. Hope what little info is here helps some guys out. Now all of this is just my 2 cents. Some may not agree with everything said. Also I barrowed a few pic's from here and there. If one of these is yours and want it removed just PM me and I replace it. Part Two: Well this is way I started this with my 2.2.  Step: 1Tear apart your Clod axles and set your gears in a clean place. With the grease on the gears they will pick up everything on your work bench. And you don't want anything extra floating around in the gear case.   Step 2: Install two 8x12mm bearings into each end of the Knuckles and one 8x12mm bearing into the end of the Axle tube.  Step 3: Slide the New TTR Striaght axle throught the axle tubes. Now add your 6mm Washer and 5mm C-Clip into place. Just like whats in the Pic.  Step 4: Now install the axle tube and the Knuckles into one piece.  Step 5: Bolt the axle tubes to the Gear cases and put everyting back together the same way you took it apart. Don't forget to use Loc-Tite on everything that can use it. You don't want those bolts backing off and floating around in with the gears.   Step 6: Intsall the new plastic hex, Pin and the O-Ring. I grinded off the outer lip on the Hex's to reduce the odds of stripping my Wheel Hex's. That same method is used on stock Clod hex's.  Now on to the CVD's Step 1: Same as above. tear you Clod axle apart and keep track of everything. Step 2: Start putting your CVD's together. First spread a thin layer of the MIP Tube on the round couplings.  Step 3: Now place the couplings in the out axle shafts. The place the outer axle shaft into the inner axle shafts cups. Then run the supplied pins through the Axle cup.   Step 5: Install the grub screw and add loc-tite to it. Now the Coupling is only threaded on one side.  Now just put them together just like above in the Straight axle How to. |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Here are the side by side shots of the TTR axles and the Stock Clod axles.   I measured my track width with everything bolted up. I was right at 12.5in wide. Any wider I wouldn't be legal. But I have a new set of tires and I'm Making some custom 2.2 Wheels. That anyone should be able to make at home with simple had tools. I hope with the new wheels and tires. I will be at the 12in mark. |

| |  |

| | #3 |

| RCC Addict Join Date: Dec 2005 Location: Beaver Falls

Posts: 1,166

|

Maybe i missed it but how do i mount my stock 12mm hex to the straight axle shafts? Isn't the end supposed to be splined like the stock axles? It doesn't seem to be splined in the pictures. Confused.....

|

| |  |

| | #4 |

| MWRCA'er Join Date: Apr 2004 Location: Machesney Park IL

Posts: 3,995

|

You use the included plastic hex.

|

| |  |

| | #5 |

| RCC Addict Join Date: Dec 2005 Location: Beaver Falls

Posts: 1,166

| |

| |  |

| | #6 |

| PapaGriz Yo  Join Date: Apr 2004 Location: In the garage building the wife a crawler

Posts: 13,137

|

This is some great tech here Run2, nice job and very informative.  I'll put a link to this in the sticky. |

| |  |

| | #7 | |

| I wanna be Dave Join Date: Sep 2005 Location: Dirty South

Posts: 4,064

| Quote:

| |

| |  |

| | #8 | |

| RCC Addict Join Date: Dec 2005 Location: Beaver Falls

Posts: 1,166

| Quote:

That brings the total to about the same as the rc4wd's axles. I just realized that these axles are wider so i can't use them unless i widen the front. | |

| |  |

| | #9 | |

| Pebble Pounder Join Date: Mar 2006 Location: hillsboro

Posts: 172

| Quote:

| |

| |  |

| | #10 |

| RCC Addict Join Date: Dec 2005 Location: Beaver Falls

Posts: 1,166

| No comps for me. I don't want to widen it cuz it's already wide enough. I think the tires sit perfect with the body right now. I wouldn't want it any wider. Mine's not really a 2.2 rig anyways. I just use 2.2 tires with it, but it's actually a 1:6 trail rig.

|

| |  |

| | #11 |

| Tire&Foam Extraordinaire  Join Date: Jun 2007 Location: C.I. Compound, Tyler, Texas

Posts: 5,601

|

Great write up  . Thank you for all the info. I had been wondering about the straight axles and CVD's. I am concerned about width though and being comp legal. Did you make these bead locks R2J? . Thank you for all the info. I had been wondering about the straight axles and CVD's. I am concerned about width though and being comp legal. Did you make these bead locks R2J? Will these work with the straight axles and CVD's and still be legal? |

| |  |

| | #12 | |

| RCC Addict Join Date: Dec 2005 Location: Beaver Falls

Posts: 1,166

| Quote:

| |

| |  |

|

| |