| | #1 |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

|

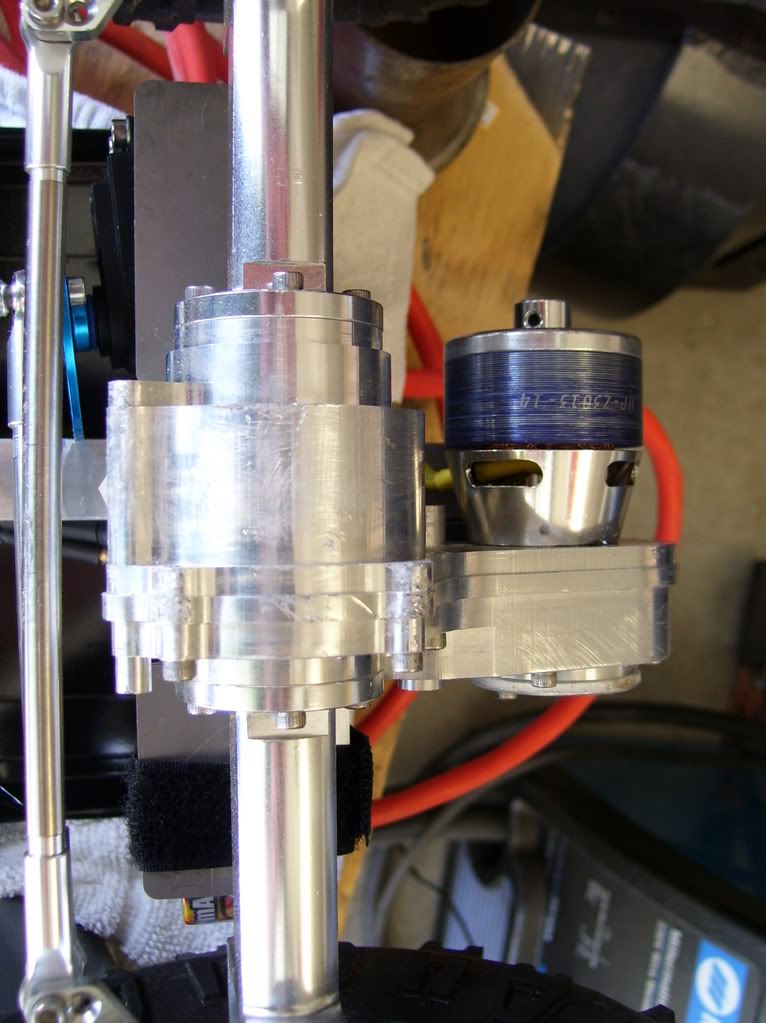

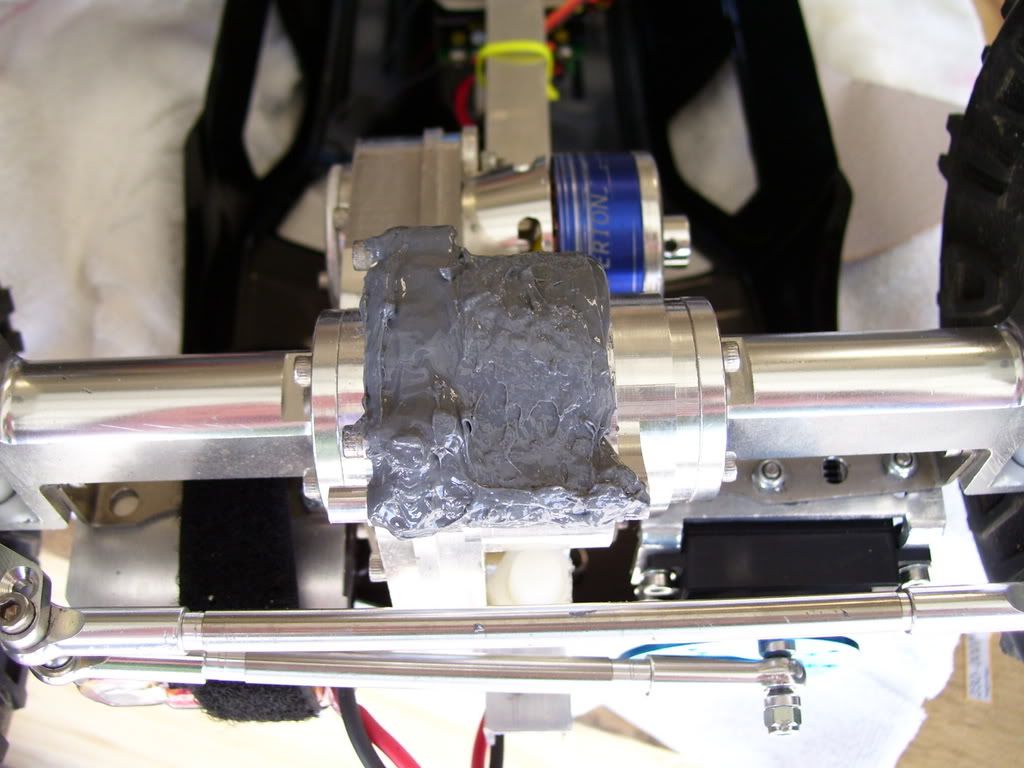

well after trying to make skid plates for my aluminum axles and not liking how any of them turned out i started thinking about some type of epoxy that would set up hard like plastic and bond good to aluminum.so this is what i found,its a 2 part self leveling(comes out like liquid)concrete joint and crack filler,supost to bond to any clean surface. i put some on a peice of card board and let it start to set up(about 30 to 60 seconds)then kinda troweled it on with a peice of plastic.after about 2 minutes you cant work with it any more,after 24 hours its hard,you can sand or grind it and it slides over the rocks and dont hang up.only down side is its a little over $50 bucks for the kit and a duel caulking gun.up side is you save your aluminum axles,it'll work on plastic axles,and you could probable do 300 sets of axles with 1 kit    Last edited by throttleboy; 03-04-2007 at 02:10 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: May 2006 Location: Arlington, VA

Posts: 3,377

|

if your that worried about scratching your axles just stick with plastic. i wouldnt put that on alu axles. |

| |  |

| | #3 | |

| Newbie Join Date: Aug 2006 Location: vancouver

Posts: 29

| Quote:

he so right . man alu axles and your worried of scratches.but thats your thing so kool . | |

| |  |

| | #4 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

| |

| |  |

| | #5 |

| Picky Fab'r/Acetal Junky  Join Date: Jul 2006 Location: Arizona Desert/AJ

Posts: 3,073

|

So run aluminum outer tubes and plastic gear cases |

| |  |

| | #6 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

| |

| |  |

| | #7 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

!! !!

| |

| |  |

| | #8 |

| Pebble Pounder Join Date: Oct 2006 Location: Enterprise

Posts: 194

|

That stuff actually looks like plastic on there. Pretty neat.

|

| |  |

| | #9 |

| Rock Crawler Join Date: Feb 2006 Location: Easthampton

Posts: 747

|

if you need to get into the axles again, how easily is that stuff gonna come off so you can split the halves?

|

| |  |

| | #10 |

| Pebble Pounder Join Date: Nov 2006 Location: northampton

Posts: 194

|

You could have easliy made a small skidplate out of alum sheet or steel. i wouldn't have spent tons on alum axles and goop them up. But that's just me. i'll post photos soon of my progress on my new project. just waiting on a body

|

| |  |

| | #11 |

| Pebble Pounder Join Date: Sep 2005 Location: Columbus

Posts: 154

|

Afraid to scratch your rock crawler......what is that all about....?

|

| |  |

| | #12 |

| Quarry Creeper Join Date: Jan 2007 Location: Alberta, Canada

Posts: 308

|

I think he didn't care about scratches but didn't want holes.

|

| |  |

| | #13 |

| Rock Crawler Join Date: Apr 2006 Location: louisville

Posts: 814

|

its alum if no ones wore through the plastic ones i wouldnt worry about alum

|

| |  |

| | #14 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

!! !!

| |

| |  |

| | #15 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

| |

| |  |

| | #16 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

| |

| |  |

| | #17 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Did you ever sand that down and smooth it it? Looks fugly.... |

| |  |

| | #18 | |

| I wanna be Dave Join Date: May 2006 Location: Arlington, VA

Posts: 3,377

| Quote:

| |

| |  |

| | #19 | |

| Pebble Pounder Join Date: Nov 2006 Location: Fernley,NV

Posts: 135

| Quote:

| |

| |  |

| | #20 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Well get to it ot let the rocks do it.... |

| |  |

|

| |