| | #1 |

| Rock Crawler  Join Date: Jul 2008 Location: River Falls

Posts: 673

|

I want to start shaping my own aluminum parts, and I'm sure I need to upgrade from my Dremel, but I cant afford a $500 lathe..What are some quality options for less than $150? It doesn't need to be CNC-quality stuff, but I want to do better than I am now...Or am I just underestimating my Dremel? Would it work if I got a workstation/drillpress for it? Thnx in advance...

|

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Feb 2008 Location: UK

Posts: 818

|

What kind of parts do you want to make? Nearly everything can be made the old-fashioned way, using a hacksaw, drill bits and files. |

| |  |

| | #3 |

| Rock Crawler  Join Date: Jul 2008 Location: River Falls

Posts: 673

|

I just wanna make some decent-looking shock mounts, chassis, etc.. I think I lljust buy a little band-saw and shape with my dremel... |

| |  |

| | #4 |

| Newbie Join Date: Jul 2009 Location: Bay Area

Posts: 41

|

A little bandsaw might be a good investment, but before you buy that spend some money on a good quality set of files. Seems most people look down their noses these days on them, but you can do a LOT of nice work that way. I usually find that for many simple small parts it is easier to shape a part with files than to set up the mill or lathe.

|

| |  |

| | #5 |

| Rock Crawler Join Date: Feb 2008 Location: UK

Posts: 818

|

fastev is right - learn to use simple hand tools. Only use a power tool if it's going to save time. I've got a dremel with a flexi-shaft. I use it for roughing-out parts that can't be cut with a hacksaw, but finish by hand with files and paper. You've got so much more control over a Swiss file than a dremel. There are only 2 power tools that are really needed for fabricating parts - a pillar drill and a lathe. If you are only working with flat plate or sheet, you don't need the lathe. |

| |  |

| | #6 |

| Pebble Pounder Join Date: Dec 2008 Location: Tomball, Tx

Posts: 168

| |

| |  |

| | #7 |

| Pebble Pounder Join Date: Feb 2009 Location: Hiding in the laundry room!

Posts: 137

|

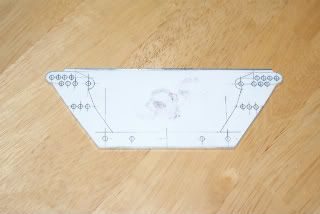

I also have to agree with fastev and clockworks unless you are doing a lot of cutting a hacksaw and a nice set of files is all you need. When I use my dremel I take longer than using a hand tool. I'm so worried bout it getting out of control I go slower than I would with a plain old hacksaw More hand done inspiration, my new chassis I'm working on. broke the proto/plastic one today so switching to aluminum. All work on it so far is with a hacksaw/files and bout 30min work.  Anyhow good luck. Take your time and do it right the first time. |

| |  |

| | #8 |

| Picky Fab'r/Acetal Junky  Join Date: Jul 2006 Location: Arizona Desert/AJ

Posts: 3,073

|

I have made numerous pieces in both alum and acetal like chassis, mounts, plates and whatever else that I felt I could. I've only used a jigsaw for the rough cut, a drill press, a dremel, and some files/sand paper. I rough cut the shape as close as I can using the jigsaw. Then using a sanding drum attachment from dremel, I chuck that up into my drill press...adjust the table up so the sanding drum is through the center of the table a bit...and then lay my parts down on the table and push it into the sanding drum. It's a fast way to sand down those edges and still keep the edge perpendicular to the sides. I use mini files for those corners that I couldn't reach due to the diameter of the sanding drum. |

| |  |

| | #9 |

| Rock Crawler  Join Date: Jul 2008 Location: River Falls

Posts: 673

|

Thanx for all the help, you guys!

|

| |  |

| | #10 |

| Pebble Pounder Join Date: Jul 2009 Location: Lehigh Valley, PA

Posts: 100

|

Don't forget a couple pieces of angle iron, some c-clamps and a hammer to make bends.

|

| |  |

| | #11 |

| Newbie Join Date: Jun 2008 Location: Barstow

Posts: 37

|

I use the same tools as above but I'd like to recommend Mac brand files. I'm not one of those dudes that only buy Mac tools but they files rip through stuff dang near faster than a hacksaw can. Shaping mulpipals of the same part? Bolt them all together and shape it a one piece. |

| |  |

| | #12 |

| Quarry Creeper Join Date: Apr 2008 Location: sanford

Posts: 228

|

i do a lot of work with a scroll saw then i hit it with a rotary tool like thtis  this was the crawler this was the crawler this one was the mud truck  i just make them fast b/c i don't keep them long a few runs then on to some thing new |

| |  |

|

| |