| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Nov 2009 Location: independence

Posts: 58

|

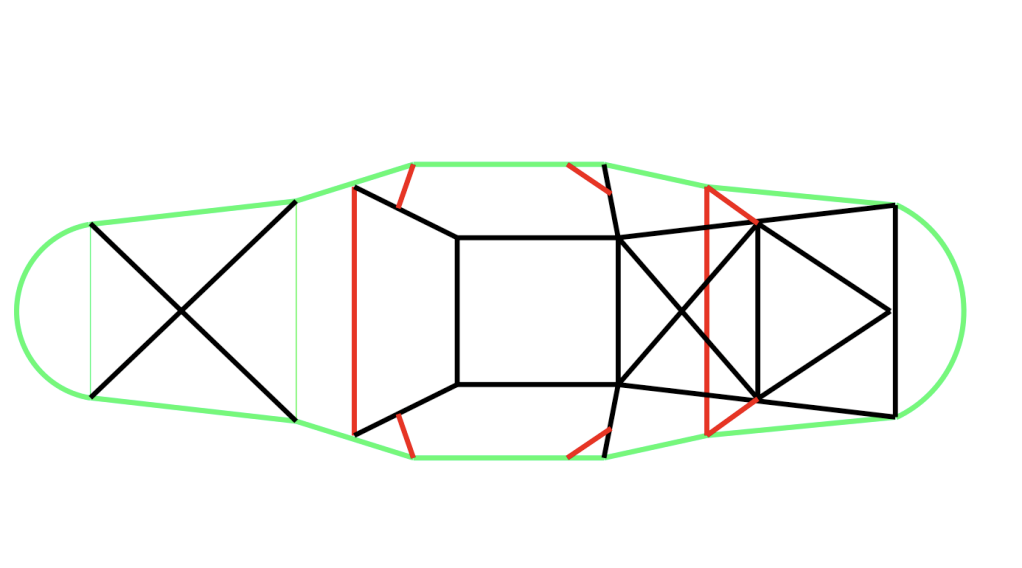

OK so what is the proper way to to make exact bends for frames. Say i am going to build a tuber frame witch i plan on doing a rock crawler and i want to make the outer part of the frame (green) out of one single piece of tube what would be the best way to make the bends the same on both sides.:confused:  i have already built a rail frame but i just eye-balled it and i built each side separate then soldered them together witch worked but the next frame i am going to braze and i want to build it as strong as possible so i want to make it all out of one piece of tube.      |

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Jul 2009 Location: East Troy

Posts: 30

|

What kind of tubing did you use on that one?

|

| |  |

| | #3 |

| Rock Stacker Join Date: Nov 2009 Location: independence

Posts: 58

|

1/4 inch brake line with 3/16 inch for some of the braces.

|

| |  |

| | #4 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

I use a tight radius brake line bender for mine.

|

| |  |

| | #5 |

| SORRCA Committee Member  Join Date: Dec 2008 Location: Parkston, SD

Posts: 4,523

|

Just print your CAD drawing out to size and use it as a guide. When I do repetitive pieces, I tape two long sticks for tube/rod, I use 3/16" cold rolled, together and cut and mark them so they match. That works good with my AX10 chassis because I use a break for the bends, two pieces at a time then. But for my custom stuff I use a tubing bender. Useful tools for me are a angle finder and combination square. Also measure, check, measure and check and measure some more. I just about never use a jig, all by eye.  By the way, nice work and the rail. By the way, nice work and the rail.

|

| |  |

| | #6 | |

| Rock Stacker Join Date: Nov 2009 Location: independence

Posts: 58

|

Any idea how i can use a 20 ton press for a break do you have any pic's that i could check out. Quote:

| |

| |  |

| | #7 |

| Rock Stacker Join Date: Nov 2009 Location: independence

Posts: 58

| |

| |  |

| | #8 |

| SORRCA Committee Member  Join Date: Dec 2008 Location: Parkston, SD

Posts: 4,523

|

Here's is what I use for tighter bends. Four foot box and pan brake since I use cold rolled solid 3/16" rod.  Super I built with the brake    Link to tubing bender that I use. http://www.robinair.com/products/detail.php?id=1026 FJ40 built with the tubing bender   Can you get or make a bending die for your press? I know I've seen them used like that. |

| |  |

| | #9 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

i agree the best way to do it is to print out your design to scale size you want.use a nice brake line bender. i didnt use one.for my 90's i would pinch it in the vise so the tube wouldnt collapse.thats why most use solid rod. i have built mine from 3/16" brake line. as long as it brazed good i wouldn't see any problems with strength. they both held my wieght standing on them(150 lbs) the first one i built was eying it. everything was off. the second one i did. i spent time drawing it out on paper to the size i wanted. locating shock mounts and link mounts in it also. along with lots of measurements.bent up each piece and compared it to the drawing, then pieced it together. when i made it i wanted to do the base of it all one piece to. that didnt happen. two pieces were much easier. my second one came out perfect. all in all take your time. taking your time and well planning will pay off  . the first one i did took about 6 or 7 hours. all in one shot. my second one took me a week and a half. good luck . the first one i did took about 6 or 7 hours. all in one shot. my second one took me a week and a half. good luck

|

| |  |

|

| |