| | #1 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

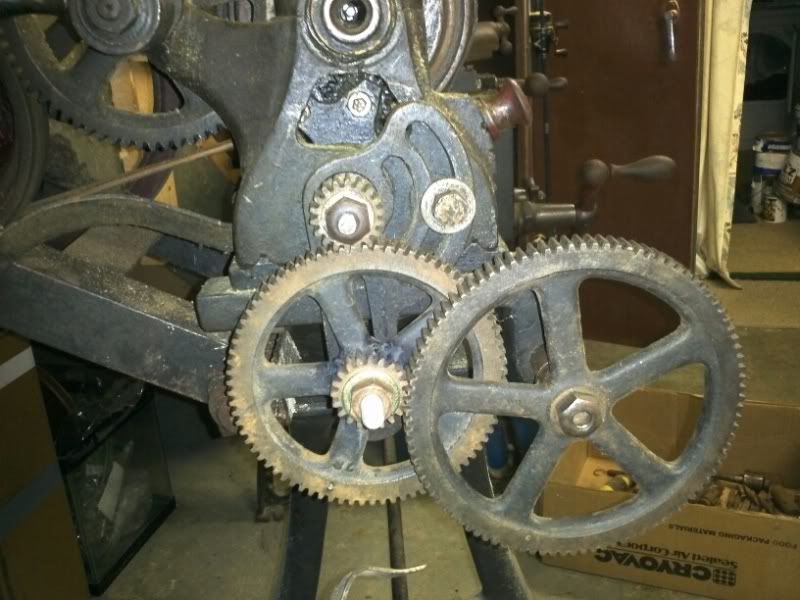

Ok just finally got around to digging out my grampas old lathe my mom thinks its from the 40s but who knows all i know is that its awesome LOL. Anyways i got it all together and running and am having an issue. First off sorry for my horrid lingo as i go on trying to explain my problem. In short the apron/saddle(entire unit that holds the cutting bits and is adjustable) moves to fast when engaged. It makes it like its threading the piece i am cutting. I tried messing with the gearing to no avail. I used to work run a bike shop so i under stand that the smaller the gear that is giving the power and the larger the gear it is spinning will make it spin slower. But im at the smallest i have and the largest i have already and its still moving to fast. There is a 3rd gear between them but that seems to just be an idler gear at least in my head that should change the gear ratio. Im looking at pictures now the Leadscrew is spinning to fast. If needed i can take pictures of the gearing set up if it helps anyone. Any help would be great im not sure if i need different gearing or what and ill throw in a pic just for fun.  |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave  Join Date: Dec 2009 Location: San Francisco

Posts: 2,236

|

Take a better picture of the controls. I have never worked on something that old, or even seen one so I cant say for sure but typically that lead screw would be for threading. On the newer lathes I have worked on there is just a small motor that turns the crank and you adjust speed with a knob that controls a pot to the speed controller. |

| |  |

| | #3 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Yep i just had my one buddy stop by and he pretty much said the same thing that its more of a threading machine. Ill have to see about rigging up a motor to drive the lead screw separately. And after cleaning some dirt off it its got a few 1890s dates on it so this thing is even older than i had thought. It is tons of fun though just messing around with stuff. |

| |  |

| | #4 |

| RCC Addict Join Date: Oct 2007 Location: Kennewick, Washington

Posts: 1,382

|

Older lathes like that only had one feed screw and you changed the feed rate by changing gears on the back of the headstock.The gears would add up to a certain inch per revolution or thread per inch. You have a very nice lathe there ! Did you get a box of gears with it? This is the only way to change the feed rate.

Last edited by Cave Dave; 09-13-2011 at 09:02 PM. |

| |  |

| | #5 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Yea i have a stack of gears but can only get it to go slow enough for a super fine thread not a machined smooth surface.

|

| |  |

| | #6 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

The small gear is a 18 larger gears are not labled  Smallest gear i have left over is a 20 and again the larger gears are not labled for what ever reason but are smaller than what i have on there now  |

| |  |

| | #7 |

| I wanna be Dave  Join Date: Dec 2009 Location: San Francisco

Posts: 2,236

|

You should be able to get a good finish by using the hand wheel. What I was talking about was actually a motor that spins the hand wheel not the lead screw. Takes some practice but a nice even feed is surely possible with hand feeding. Get yourself some a couple of bits with carbide inserts and a quick change tool post and some holders and you will have a nice setup.

|

| |  |

| | #8 |

| Quarry Creeper Join Date: May 2009 Location: brentwood

Posts: 324

| |

| |  |

| | #9 |

| Rock Crawler Join Date: Jun 2010 Location: Yelm,WA

Posts: 695

|

Would love to see that thing all restored, bet it would clean up pretty good  |

| |  |

| | #10 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Yea I need to go through it and clean and grease everything before I try and actually cut anything

|

| |  |

| | #11 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

I think old machines like that are pretty cool. Take a page from Jason in Augusta's book and restore that thing properly  |

| |  |

| | #12 |

| Pebble Pounder Join Date: Oct 2008 Location: Grand Junction, CO.

Posts: 167

| Here's a guess from using a similar old lathe my Grandfather had. In the picture on the top. The big hub between the Yoke that holds the spindle (behind the chuck) and the belt should have a bolt in it somewhere, typically on the side near the yoke. If you loosen that bolt it should de-couple the spindle shaft from the belt drive assembly. Don't usually have to remove the bolt just loosen it, it can be a booger to get back in. Then in the second picture you can pull the idler shaft with the handle on the end of it up and it'll run much much slower. From the looks of the pictures I was using a very similar machine about 2 months ago. Last edited by MystRacing; 09-14-2011 at 10:51 AM. |

| |  |

| | #13 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Yes you are right on with that I found that and got excited but still the lead screw and the chuck will spin at the same speed as one another its slow the entire machine down not just one part ill try more when I get home one way or another Ill make it work haha

|

| |  |

| | #14 |

| Pebble Pounder Join Date: Oct 2008 Location: Grand Junction, CO.

Posts: 167

|

Didn't think about the fact it doesn't change the relative speed. This is an Edit........ I had a blurb about reversing rotation but after thinking about it the extra gear won't effect the direction of rotation so it doesn't matter if you can reverse it or not. That's one part that differs from my Grandfathers, his has 2 lead screws that run in opposite directions and above and below each other. There is a double half nut in the middle so if you pull the lever up it goes one way and push it down it goes the other. I'm guessing yours is older than his. Last edited by MystRacing; 09-14-2011 at 01:44 PM. |

| |  |

| | #15 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

You my friend are a genius that is what I will try when I get home that is way easier than what I was thinking of thank you thank you

|

| |  |

| | #16 |

| Pebble Pounder Join Date: Oct 2008 Location: Grand Junction, CO.

Posts: 167

|

Your welcome. I'm sure it's designed that way. The spacer on the end of the lead screw shaft and the gear should just swap positions, and I'd bet money that center bolt is just the rite size to add a gear to the outside of the middle gear, or maybe there's a spacer behind the middle gear and it moves closer to the machine. I'm sure you'll figure it out. I actually feel kind of dumb that I didn't notice it sooner. Here's the table for the change gears on a 7X mini lathe like I have been using for 9 years. You can see by the picture you can run three gears in lline or slide the bottom one over and run four. When not threading it uses a 4 gear combination.  Last edited by MystRacing; 09-14-2011 at 01:50 PM. |

| |  |

| | #17 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Welp here is what ive come up with. Its not perfect but it works i think the best part was that i had to use the lathe to make a sleeve with a top hat to fix the lathe   And thanks everyone for the help especially MystRacing who hit the nail on the head with how to fix it i owe you a beer and dinner haha  And well on to the next question is there a decent priced starter set of bits or some must have bit that you guys recommend. Everyone is saying carbide bits so im looking to pick a set up. |

| |  |

| | #18 | |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

| Quote:

How about some close ups to the tool holder area? | |

| |  |

| | #19 |

| Rock Crawler Join Date: Jan 2007 Location: West Seneca

Posts: 770

|

Well right now the bits I have are mostly 5/16 and the holder itself looks like its been broke a few times so I was thinking of getting new holders and cutting bits http://www.harborfreight.com/20-piec...kit-43536.html I was thinking I would need something like this it is like what I have I also have some cutting bits that don't need a holder like that because they are a solid piece about 1" by 5/16th Again sorry I'm new to this but all thehelp is awesome |

| |  |

| | #20 |

| Pebble Pounder Join Date: Oct 2008 Location: Grand Junction, CO.

Posts: 167

|

I don't think I'm going to be much help on the tools. I am pretty sure the tools in the link are 1/4" unground. Smaller than you want and you'd have to grind the tools before you can use them. They should work and you can get 1/4" indexable carbide tools for them. I looked around a bit and couldn't find anything that looked correct and in the 5/16 size range. Most hobbyists use indexible carbide tools, like these. http://www.littlemachineshop.com/pro...=1669&category= I have both HSS and carbide inserts, they are typically either 1/4", 3/8" or 1/2". The 7X lathes come with square 5/16 sized bits but most people switch to a quick change tool post with 3/8" tools. I'd recommend you go over to cnczone.com and put a post in the general metalworking machines section, the guys over there can probably tell you everything there is to know about that lathe including where and what tools you need to get. Last edited by MystRacing; 09-15-2011 at 02:23 PM. |

| |  |

|

| |