| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

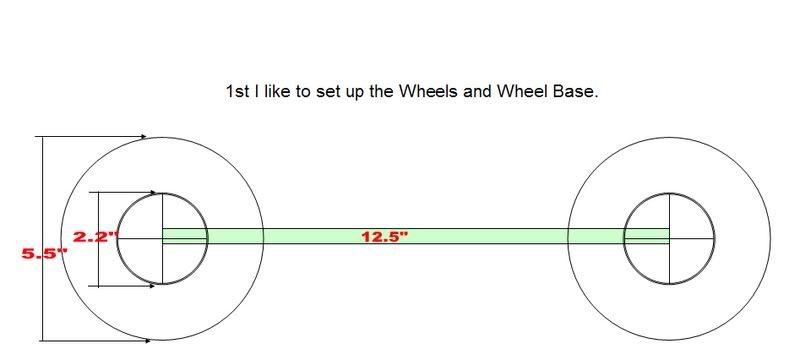

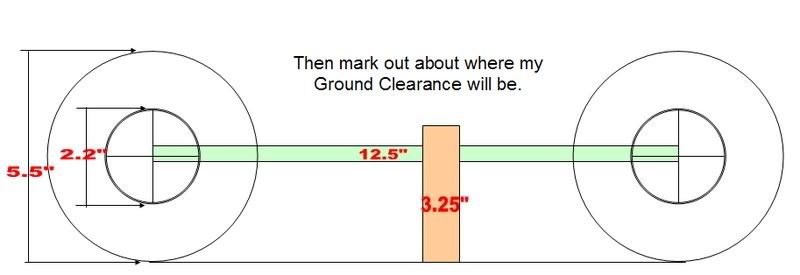

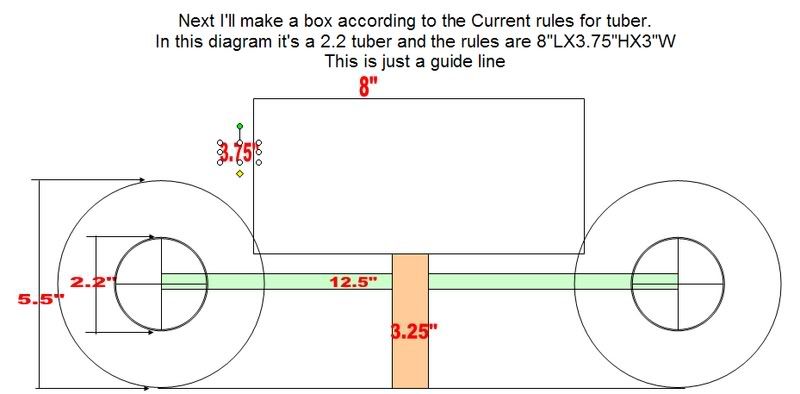

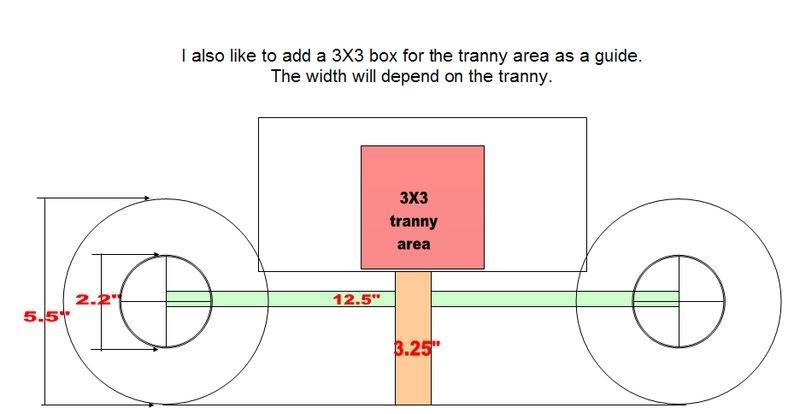

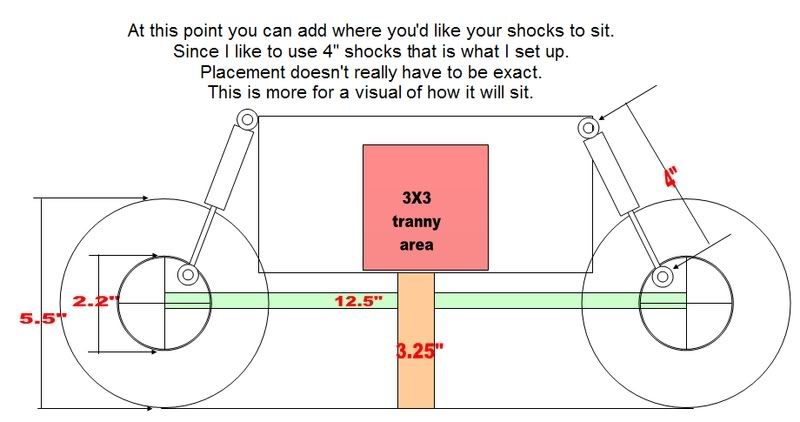

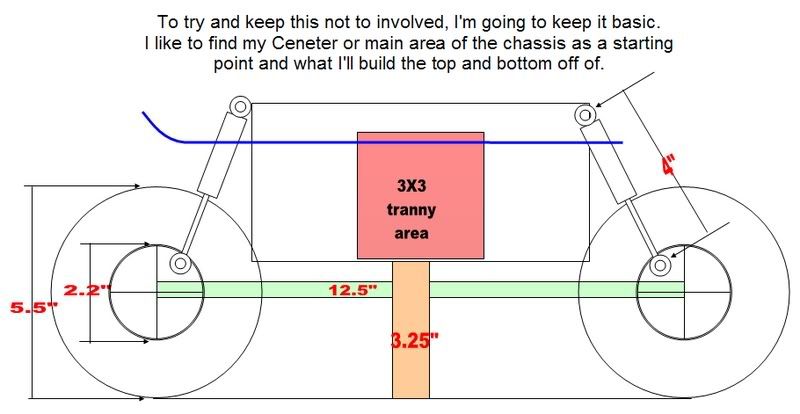

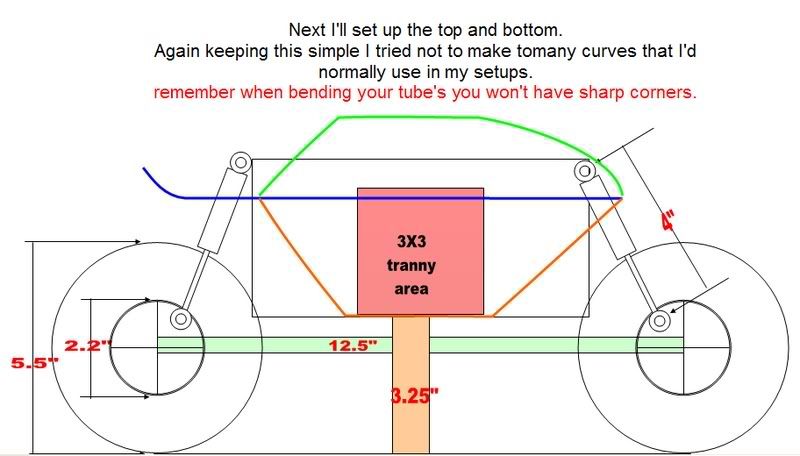

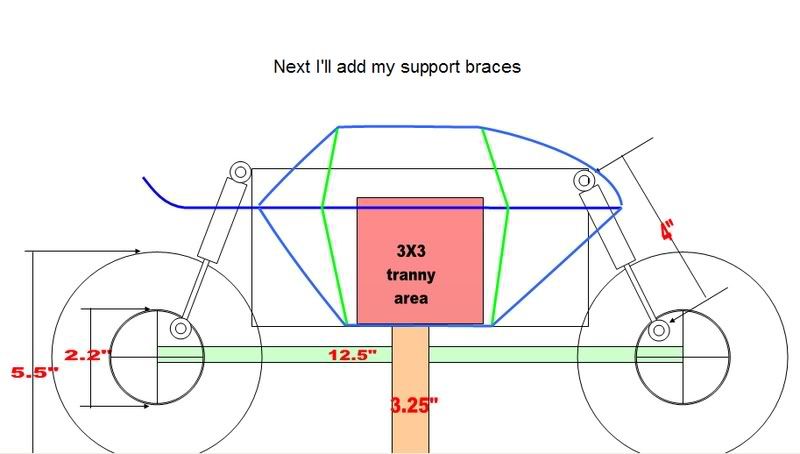

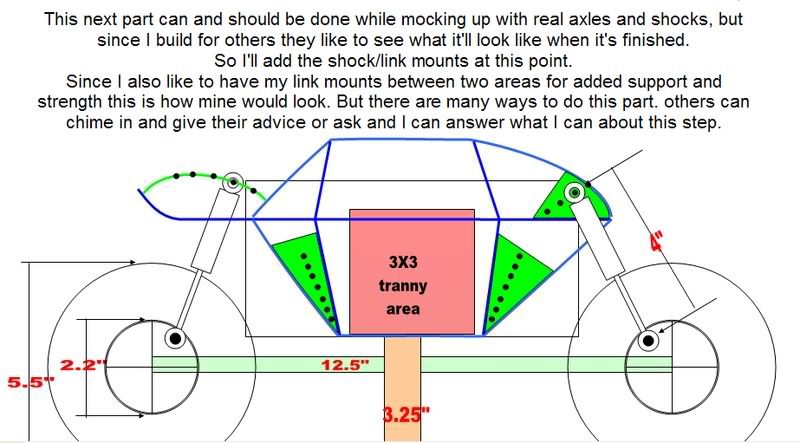

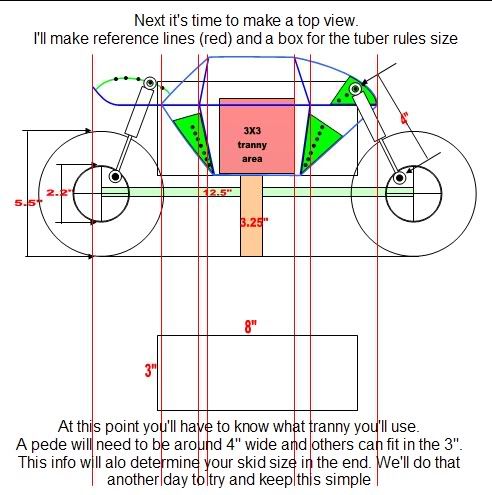

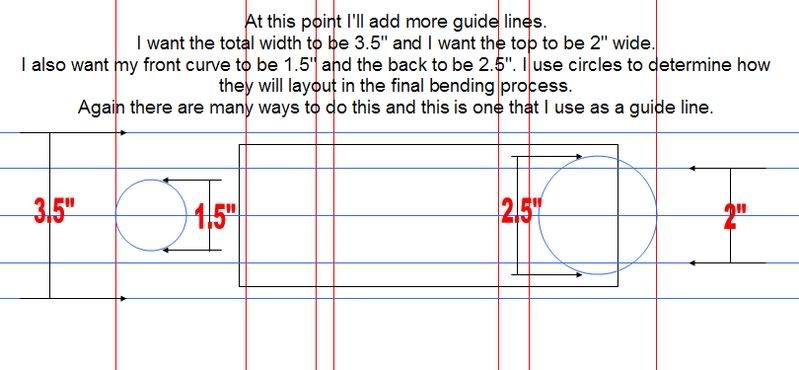

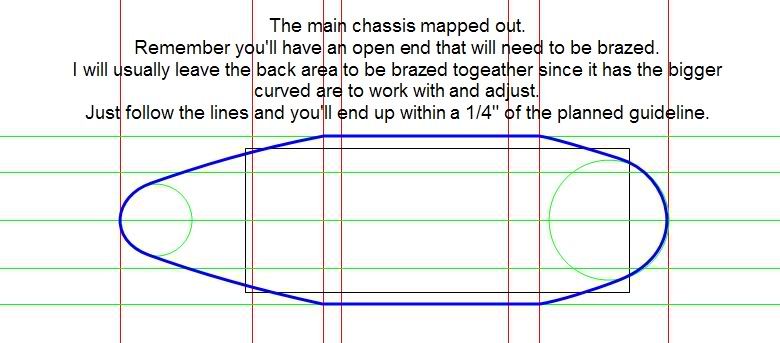

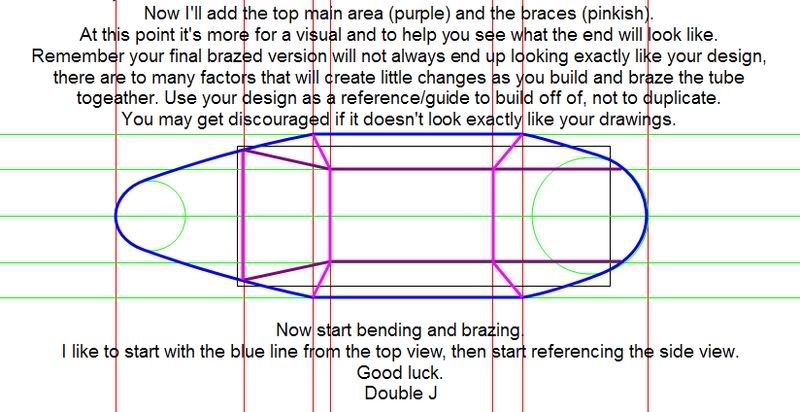

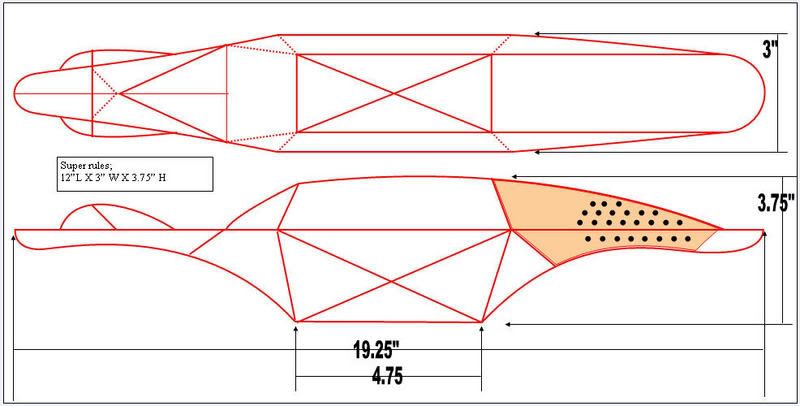

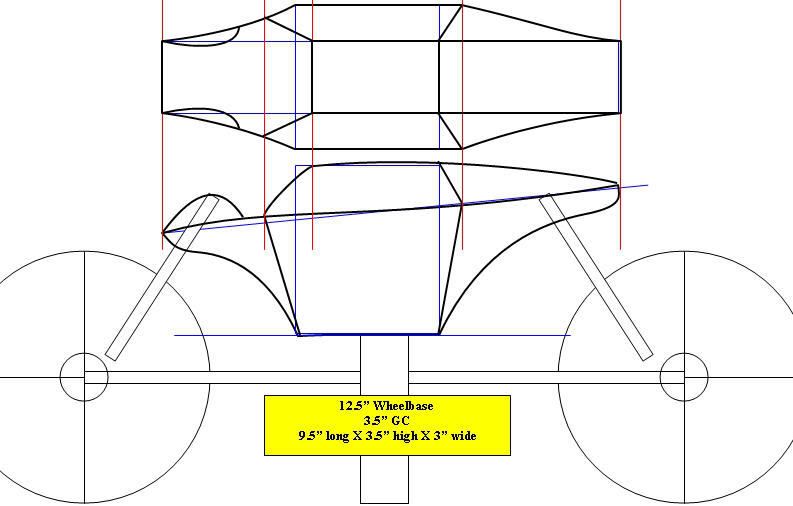

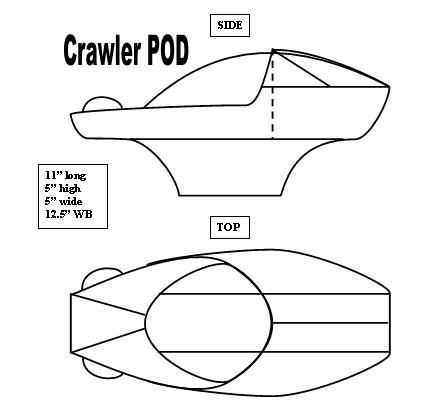

Thought I'd through this togeather in hopes of helping someone out when they decide to build their own tuber. Since I build for others 99% of the time they like to have something to look at before I ever start bending and brazing. so I thought I'd take you on a little trip through my planning process. I tried to keep it simple as to not get to complicated. I do encourage others to add their 2 cents on what they may or maynot do. I also know that I do some things different that my be or may not be more difficult to others. For example: I like to have curves on my tubers some hate them some don't, some just can't do it and some can. I made this with almost no curves for simplicity. so take this for what it is.  You'll also need to understand that no matter how well you plan (with some exceptions) your end result will never be 100% identical to your drawing plans.              |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

|

Double J, I think what you have done here is wonderfull!! Although I have my own method, I still learned some things from your post here. I realy like to see stuff like this on here. Informative, inovation. Deffinatly one of the best informative posts Ive seen here. So ...... I may use this in the future, my way isnt always the best way so Im open to new things always. Just want to say thanks! Shawn |

| |  |

| | #3 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

Thanks I appreciate the positive feed back. I understand that there is more than one way to do this for sure. I know my way may not be the best way for others and vise versa. But I think this will get the ball rollen for some folks and will help some that may have been doing it for a while. I would like it if other builders would share how they do things. I know I'm always willing and wanting to learn new things or tricks. |

| |  |

| | #4 |

| PapaGriz Yo  Join Date: Apr 2004 Location: In the garage building the wife a crawler

Posts: 13,137

|

Very nice, and helpful, I'm sure this will help alot of people DubJ.

|

| |  |

| | #5 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Do you typically provide a nice drawing like this when working with a customer purchasing a Double J tube chassis or other tube products from you?

|

| |  |

| | #6 |

| I wanna be Dave Join Date: Apr 2004 Location: SoCal

Posts: 5,027

|

Good stuff Double J. Thanks for sharing. One note for the uninformed who are building a rig for competition, to meet current tuber rules, it should resemble in some way a 1:1 chassis. |

| |  |

| | #7 | ||

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

Thanks Grizzly.. Quote:

Quote:

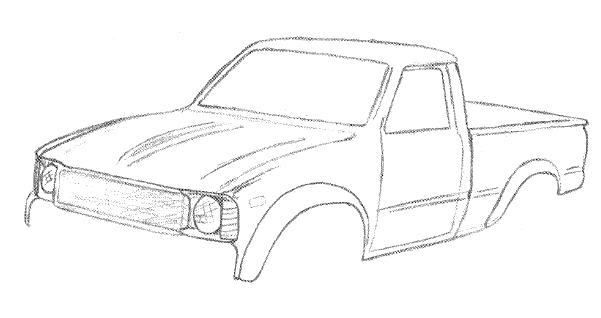

On some of the more scale stuff we'll get the basics or I'll even draw a close to real of the body and make the designs off that. like in the last pic it's a Bruise (yota) I'll use a pic like this to show what an exo may look like or custom bumper. other times I'll use a real pic I snaged off the net and design around that.  This one was done before the current rules.    | ||

| |  |

| | #8 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Thats really a great way to insure customer satisfaction very professional. Thanks for the schooling on your design process  |

| |  |

| | #9 |

| Quarry Creeper Join Date: Oct 2006 Location: where fear and common sense don't get in the way

Posts: 451

|

Thanks for another great write up  . What CAD program are you using, all I have are my Drafting tools. They work so far, but a CAD program would be alot nicer. . What CAD program are you using, all I have are my Drafting tools. They work so far, but a CAD program would be alot nicer.

|

| |  |

| | #10 | |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| Quote:

Thats funny right there. I wish I had a computer that I could load cad on to. I need to sell quite a few more Tubers, Bulls and Trailbeaters so I can buy a new computer for Christmas. I actually use MS word and the drawing tools to make them. Just goes to show anyone can do it. | |

| |  |

| | #11 |

| Rock Stacker Join Date: Nov 2007 Location: Clifton, VA

Posts: 60

|

Take it from me Double J is right, you need a plan. I am in the process of back tracking on my first attempt due to NO plan at all. I just started bending and brazing without really knowing what would come next. I may end up with something but it's going to be a surprise. I also must make better joints for looks, strength and amount of #45 use. I used up the best part of an OZ filling gaps and just over using on my first try. Must slow down and make it fit better before heating. I also made the mistake of using 1/4" tubing. That stuff is not easy to bend, stronger I guess but bigger than I needed. |

| |  |

| | #12 |

| I wanna be Dave Join Date: Jun 2004 Location: San Jose

Posts: 5,207

|

wow, you go thru all of that to build a tuber. Man, I just sketch out some designs for a bout a month or a year, get some tube and start bending. Then I usually cut something off for function re-do it and walla. I should probably be more diligant in my builds. Nah!, Nice work Double J on the write up though |

| |  |

| | #13 |

| Quarry Creeper Join Date: Mar 2007 Location: northern utah

Posts: 479

|

awesome! thanks double j, this is exactly what I've been looking for! should be stickied or put in with the tech section..

|

| |  |

| | #14 | |

| Quarry Creeper Join Date: Oct 2006 Location: where fear and common sense don't get in the way

Posts: 451

| Quote:

| |

| |  |

| | #15 | ||||

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| Quote:

Quote:

Quote:

I'll be adding this with some other info to the brazing video sticky at the top after I get alot of the info put togeather and have some help/imput from other builders like Mr.P!ink and so forth. Quote:

Again thanks everyoen for the props and look forward to having other builders post what they do when coming up with something. I'll be working on a complete start to finish "how to" on building tubers and getting input/help from other tuber fabricators. I love learning new ways to do things an look forward to others inputs and advice. | ||||

| |  |

| | #16 |

| I wanna be Dave Join Date: Dec 2005 Location: Orlando

Posts: 7,420

| |

| |  |

| | #17 |

| REST IN ALOHA CHIP  Join Date: Nov 2005 Location: *

Posts: 3,549

| |

| |  |

| | #18 |

| Quarry Creeper Join Date: Jun 2007 Location: Sacramento

Posts: 338

|

DJ, quick question: in the OP, you drew a box according to the 2.2 rules, but some of the tubes you drew go outside that box at the rear of the chassis. Was that a mistake (i.e. a ROUGH sketch) or did you purposely draw it like that? thanks! |

| |  |

| | #19 | |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| Quote:

Then draw to whatever the customer want's or what looks right/good. Some people want them to look a certain way, so that means it will end up being longer than the current rules. I've had a couple saying they wanted it to just meet the rules demensions. making it tinny. | |

| |  |

| | #20 |

| Quarry Creeper Join Date: Jun 2007 Location: Sacramento

Posts: 338

|

ahh, I get it, thanks!

|

| |  |

|

| |