| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Nov 2009 Location: Seattle

Posts: 63

|

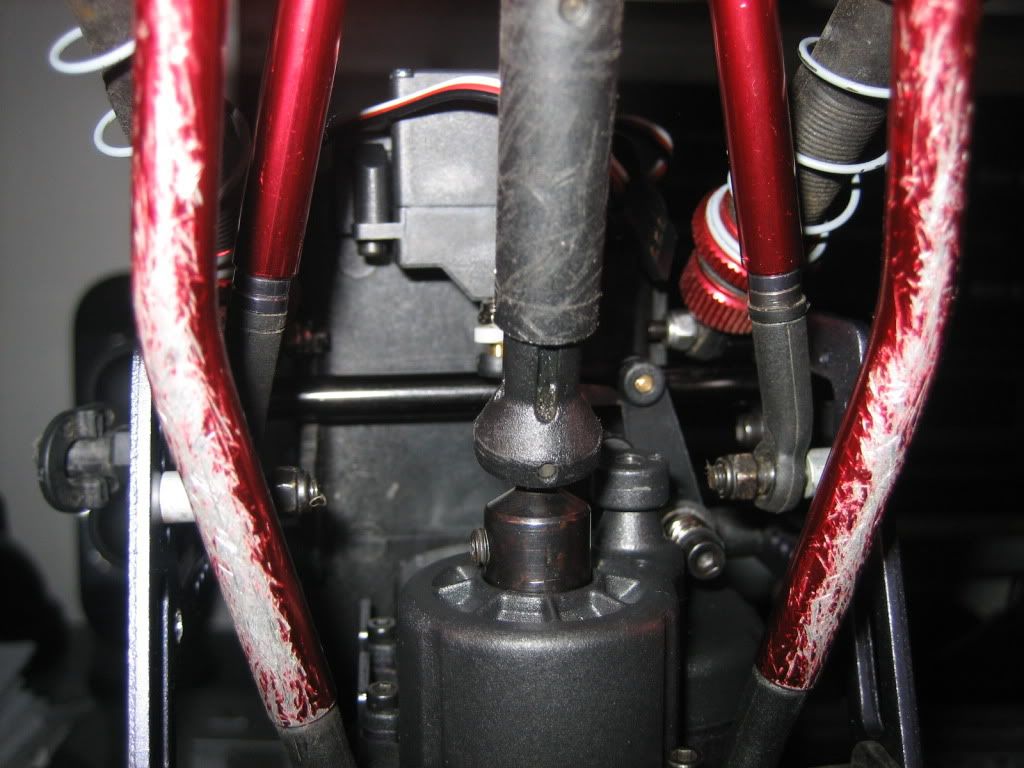

Hello everyone. I just got done installing my venom dig unit on my truck. I found it a little bit tricky mounting the servo, since I have removed the battery tray/shock mounts and made my own stage two suspension. I got it in and it works great! I was just wondering how others are mounting the dig servo with stage two suspension? I ended up cutting the stock battery tray down to a sliver that was just big enough to mount to the tranny and long enough to mount the servo to. Now that I have it in and it's working great I will probably make a mounting plate out of alum. I'll post pics.

|

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: Jan 2009 Location: Riverside Commifornia

Posts: 73

|

Id really like to see those pics. Im waiting on my ckrc stage 2 to come in the mail. Next thing after that will be the dig. It'd be great to see what Im getting into before I get into it.

|

| |  |

| | #3 |

| Quarry Creeper Join Date: Nov 2009 Location: Vacaville

Posts: 259

| I have been thinking about this also..... with all the "stage xyz" builds, I have something in the works and should have it done this coming week. It kinda goes with my latest chassis design.... I will post pics. |

| |  |

| | #4 |

| Quarry Creeper Join Date: Sep 2007 Location: NE Ohio

Posts: 267

|

I believe the 1/4elliptical has some pics of the set-up with stage 2 style set-up. I think he fabbed a bracket for mounting it.

|

| |  |

| | #5 |

| RCC Addict Join Date: Feb 2006 Location: Bellflower, CA

Posts: 1,028

|

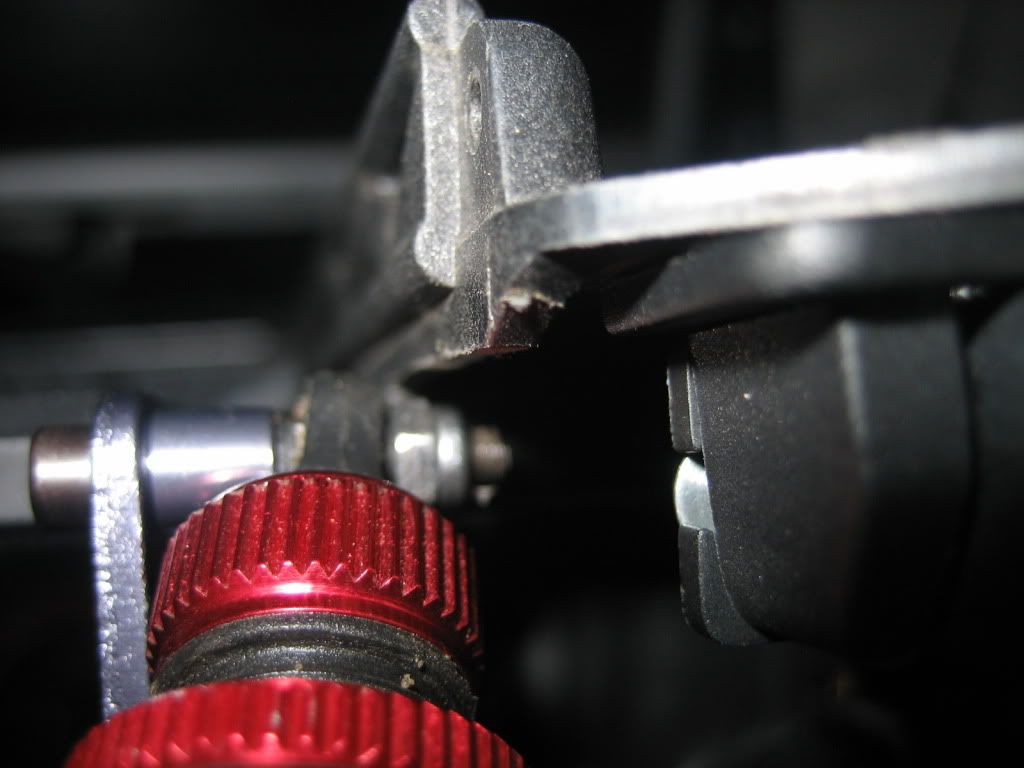

It can be done! All you have to do is get yourself a 70mm axial link and drill a small hole in between the shock mount and the body mount. Use a locknut to secure the shock and span that link across the chassis plates and your golden. Try to drill the hole either in the center of the two existing holes or slightly biased to the body mount hole. I can move the Dig linkage with no interference. Here are some pics      |

| |  |

| | #6 |

| Newbie Join Date: Nov 2007 Location: Indy

Posts: 19

|

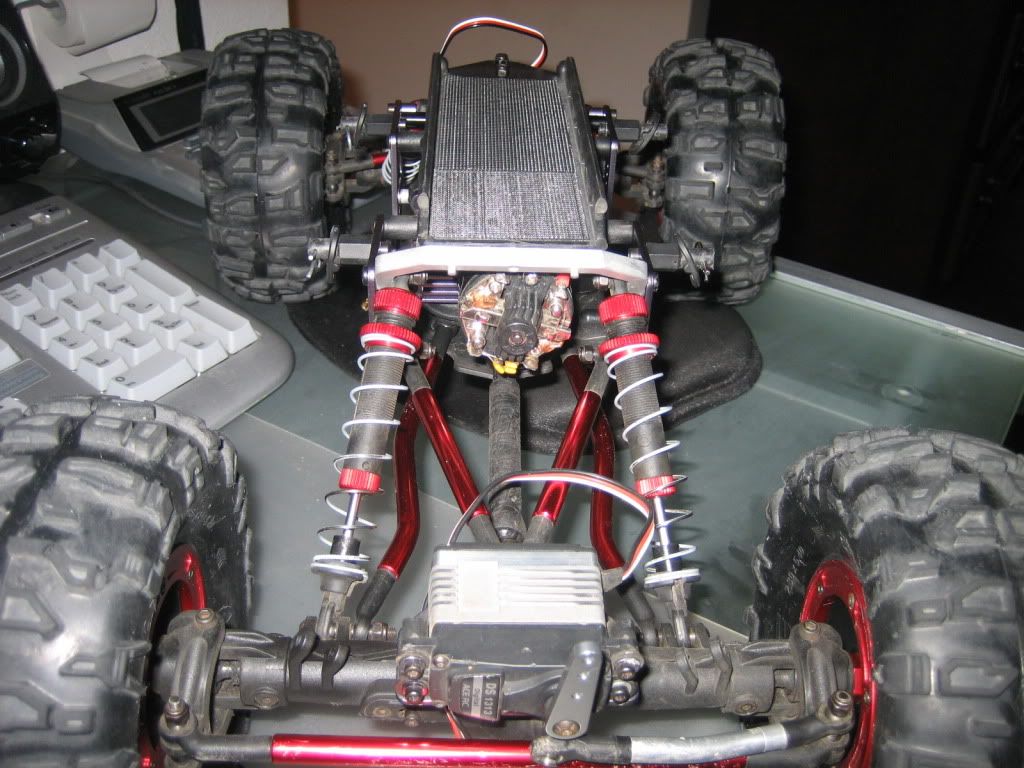

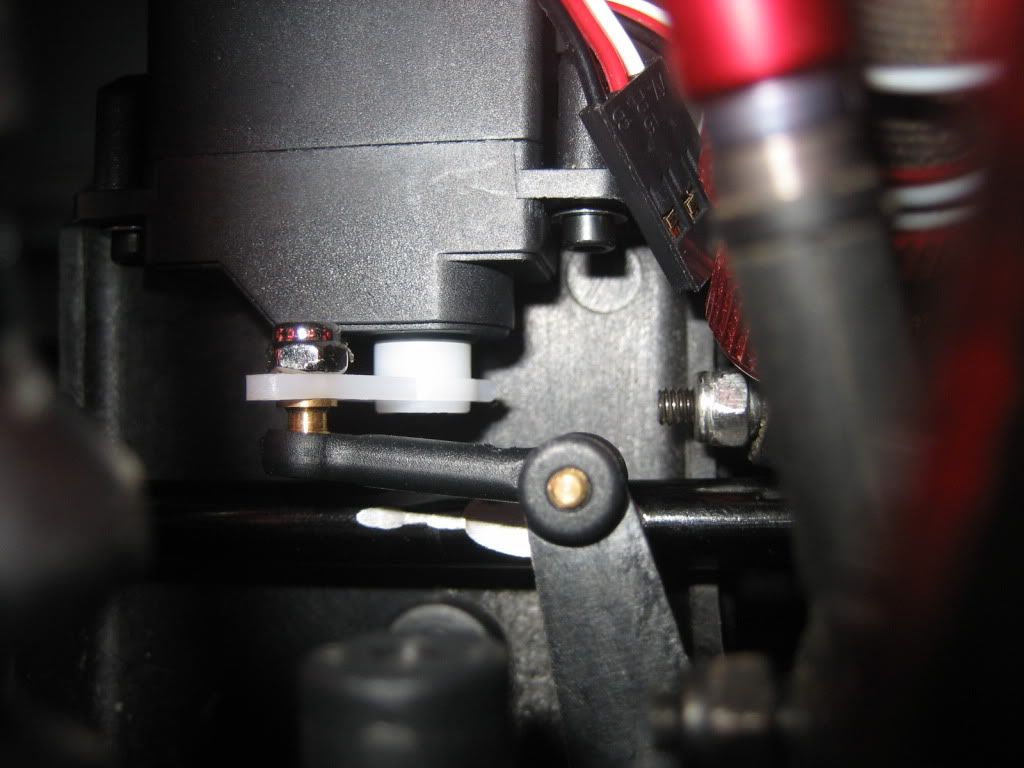

There are a few dif. ways you can mount the dig servo with no factory battery tray. This is the first way I tried and it turned out great. I just dont like the servo outside the frame. Still need to make a guard for it. My dig has started to pop/slip when I am on high traction surfaces. Anyone else hav e this happen? I used the diff lock servo since it is smaller. Also used an airplane rod w/ a Z-bend and some brake linkage from one of my 1/8 scale buggies.   |

| |  |

| | #7 |

| RCC Addict Join Date: Feb 2006 Location: Bellflower, CA

Posts: 1,028

|

Or just get yourself the venom chassis brace for an AX10 and use that as a rear shock spacer/chassis brace. I didnt have an extra one laying around so i got myself a 70mm link. Its the same brace im using for the front of my sons rig as you can see in the pics.

|

| |  |

| | #8 |

| RCC Addict Join Date: Feb 2006 Location: Bellflower, CA

Posts: 1,028

|

Oh and pay no attention to the marks on the rear chassis brace. I dremeled that out when it was bieng used on my AX10

|

| |  |

| | #9 | |

| Rock Stacker Join Date: Oct 2005 Location: Somewhere in

Posts: 53

| Quote:

| |

| |  |

| | #10 |

| Newbie Join Date: Nov 2007 Location: Indy

Posts: 19

|

Servo would hit the upper links. I tried it there first with the servo the dig came with.

|

| |  |

| | #11 |

| Pebble Pounder Join Date: Dec 2009 Location: Who Dat Louisiana

Posts: 115

|

Have you tried the servo upside down on the inside if the plate? Just like you have it but inside and upside down..

|

| |  |

| | #12 |

| Newbie Join Date: Nov 2007 Location: Indy

Posts: 19

|

I did try it upside down and inside the chassis. Then it hit the cross brace where the shocks mount. It could be mounted in there with some modification. This was the easiest (quickest) way to mount it. I was real eager to test the dig out.

|

| |  |

| | #13 |

| Quarry Creeper Join Date: Nov 2009 Location: Vacaville

Posts: 259

| Here is the direction I've gone with my Hardrock Comp stage X chassis....    |

| |  |

|

| |