| | #1 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

As of yesterday I planned on running a Dodge Dakota body to mimmick my 1:1. After doing more research last night I found out that I didn't want to use that body. I had a Parma 1/8th scale F150 body sitting around and decided to go with that instead. This body is huge! It's about 21" long, 8.25" wide and a wheelbase of 12.875" so that gives me a lot more room to put that emaxx tranny in. I did a few basic mock ups last night. As you can see this is a wide body.    I need to widen the axles 1/2". I think everyones using long axle stubs with a spacer behind them right? Here is what I want the track width at.   |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: May 2006 Location: akron

Posts: 4,054

|

that looks pretty good thing is huge i like it

|

| |  |

| | #3 |

| [HOONIGAN] Join Date: Nov 2005 Location: Grand Junction

Posts: 4,269

|

Pick-up some tamiya Blackfoot stub shafts and use a bearing or an old axle bushing for a spacer. They widen your width about a half inch. Looks good, that's definetly a BIG body!

|

| |  |

| | #4 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

I've read about the black foot axles. I have some HPI MT rear axles laying around I'm going to try. I know they are 5mm and I want to say they are either 38mm or 40mm long which would do the same thing.

|

| |  |

| | #5 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

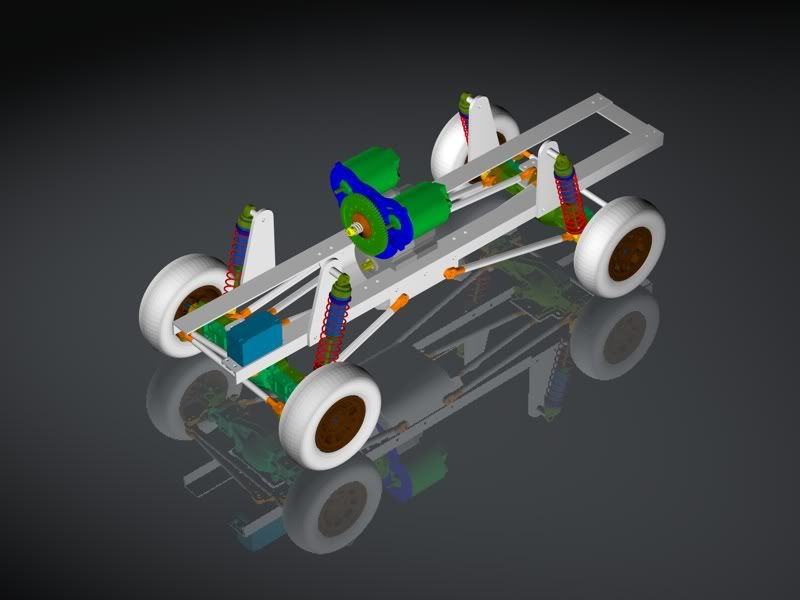

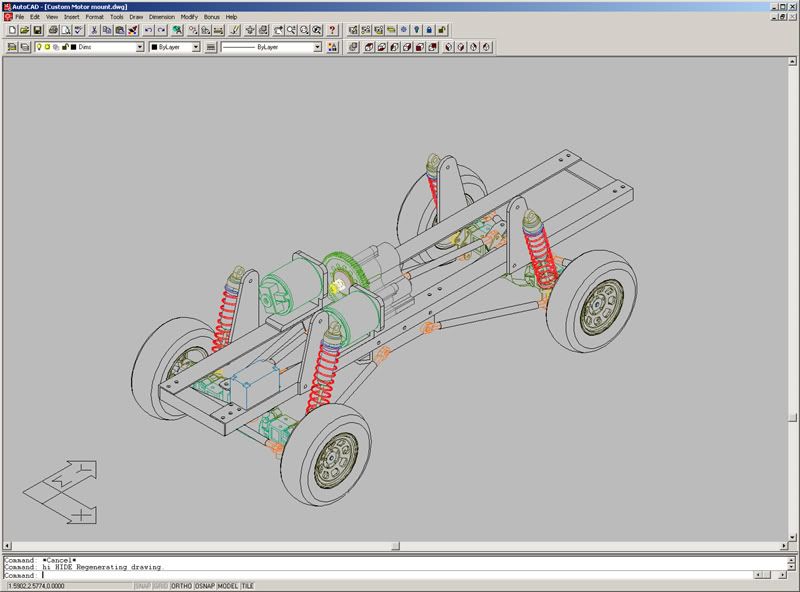

Finished modeling! time to start fabbing!  |

| |  |

| | #6 |

| Rock Crawler Join Date: Jun 2006 Location: capon bridge

Posts: 571

| |

| |  |

| | #7 |

| I wanna be Dave Join Date: May 2006 Location: akron

Posts: 4,054

|

man that looks familar i like that design  |

| |  |

| | #8 |

| Rock Stacker Join Date: Mar 2007 Location: on a lake

Posts: 80

|

what kind of software s that. and where do you buy it. also that rig is gonna be awsome.

|

| |  |

| | #9 |

| Gold Star Baby Momma!  Join Date: Feb 2004 Location: Maumelle, Ar

Posts: 713

|

Looks good, the only problem I see, your cog will be hella high which equals a lot of time spent on the roof. I just tore out the emaxx tranny and am going a different route. Hope you can make it work. Kevin |

| |  |

| | #10 |

| I wanna be Dave Join Date: May 2006 Location: akron

Posts: 4,054

| i think he has some plans for a custom motor plate hope that wasnt a secret nick

|

| |  |

| | #11 |

| I wanna be Dave Join Date: Jul 2005 Location: Cedar Rapids

Posts: 2,028

|

That body is huge. I used it on one of my rigs. Deep Water! |

| |  |

| | #12 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

Cole, that thing looks awesome! Sloppy is right, I will be modifying the motor mount. That was a stock maxx tranny in the drawing but I'm going to chop off one side and then clock it to lower the motor. It still won't have the best COG but it should be good enough for a trail truck. |

| |  |

| | #13 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

Here, I updated my tranny layout. If I don't like this then i'll lay the tranny down sideways.  |

| |  |

| | #14 |

| Quarry Creeper Join Date: Jan 2007 Location: New York

Posts: 260

|

that's impresive! i would suggest lifting it up a little. |

| |  |

| | #15 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

It's sitting with about %20 sag and that gives it about 2.25" center clearence. I'm going to make the shock mounts like the ones I made on my WK so that I can change the ride height without having to change the spring load. Pretty sure I'm using acrylic for the skidplate so it'll be slippery for sliding over rocks.  |

| |  |

| | #16 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

Got a little progress done at work the last couple days. I just have to make the plates for the axles and put the links together and will have a roller. Here is the frame put together quickly with the maxx tranny sitting in it.     |

| |  |

| | #17 |

| Rock Stacker Join Date: Dec 2005 Location: 8 feet underground

Posts: 61

|

So thats whats its for  That new tranny plate looks killer, still stickin with that design? |

| |  |

| | #18 |

| I wanna be Dave Join Date: May 2006 Location: akron

Posts: 4,054

|

sweet skid i like that

|

| |  |

| | #19 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

I'm still undecided about the motor plate. I cut the custom one out last night and fit it on. I overclocked by about 10 degrees so the motor was hitting the tranny housing. Not a big deal. For kicks I bolted up the stock plate and it actually seemed decent. I'd like to still run two motors because of the power. I have another idea I think I'm going to try. sloppy, if you want some of that stuff for the skids let me know. It's polycarbonate. Tough stuff! We have scraps of it at work and I can use the heat bender whenever I want. I'm not the best at it but I can do basic stuff ok. I had some 1/4" stuff from last year to remake that acrylic chassis I had. The stuff I used in the above picture is 1/8". |

| |  |

| | #20 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

If the stock maxx motor mount prooves to give it a way to high COG then I'll try to persue something like this. I can wire the lathes in reverse to get it to turn right correct? I know thats how they wire the rear motor in clods.  |

| |  |

|

| |