| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Nov 2007 Location: Northern

Posts: 311

|

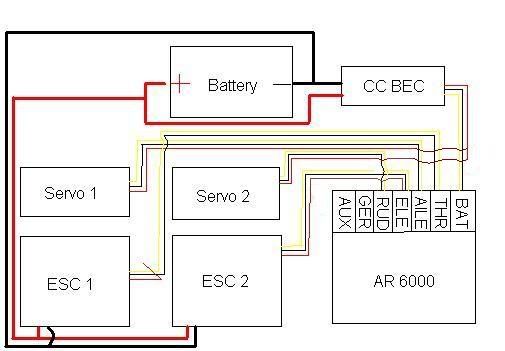

I have two airtronics servos in my super along with the 1.5" servo arms on each. The links aren't mounted directly at 1.5", They are around 1.1" from the servo swing. I set the EPA's correctly through my DX6. As you can see from the picture below, the servo arm is longer than the standard 3/4"-1". hence, more effort is required through the servo.  The wiring diagram for the rig is as followed:  Electronics used: 3 cell 11.1 lipo 2x cc sidewinder 1x cc bec 1x AR6000 2x airtronics 94780 The rig ran flawlessly at its first comp for about 5 minutes and the servos quit working before the finish gate. Both were EXTREMELY hot. The rear servo has alot of resistance whenever you steer the tire manually. The front servo still works. However, when you attempt to steer the rear through the transmitter, the front starts glitching. 1. Should I use larger 1/4 scale servos? 2. Should I wire the negative of each servo to the BEC 3. pick up smaller servo horns? BTW, Airtronics only has a 30 day warranty |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Sep 2007 Location: Westland, MI

Posts: 1,508

|

Looking at your wiring diagram you still have the a power lead coming from the second ESC disconect it. You only need power coming from the BEC. I did the same thing on my super and forgot to pull the second power lead from the rear ESC. My ESC shut down before my servos fried though I got lucky. |

| |  |

| | #3 | |

| MODERHATER™  Join Date: Nov 2005 Location: Colorado

Posts: 10,939

| Quote:

1. Hitec 805bb's and love them. 2. I don't conect the negative wire of the BEC to anything. 3. The longer the servo horn, the more work it has to do! | |

| |  |

| | #4 |

| Rock Crawler  Join Date: Feb 2008 Location: Copperopolis

Posts: 973

| |

| |  |

| | #5 |

| I wanna be Dave Join Date: Oct 2005 Location: Columbia TN

Posts: 6,154

|

There is no reason to directly wire the bec to your servos, the ar6000 is a beast and will handle the load. You need shorter servo horns. Also you probably need another bec. I run 2 bec's on my super, 5995's on 8 volts, all through the rx with no issues.

|

| |  |

| | #6 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Hey Jeff what receiver are you using?

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Nov 2008 Location: Slovakia

Posts: 308

| i can see 1-year warranty http://www.hobbypeople.net/gallery/474380.asp |

| |  |

| | #8 |

| Quarry Creeper Join Date: Oct 2008 Location: In the basement...

Posts: 473

|

Check the voltage output on the BEC ASAP - If the CC bec fails it can pass input voltage straight through i.e. 12v to the servo's... That would make them go crispy quick... |

| |  |

| | #9 |

| no talent hack  Join Date: Feb 2007 Location: Redwood City

Posts: 2,479

|

wire the negative to the servo as well, only servo signal should go through the reciever the way you hooked it up. look up Nova's arc's build thread on his super, he had the same problem

|

| |  |

| | #10 |

| Quarry Creeper Join Date: Nov 2007 Location: Northern

Posts: 311

|

I did recently look up his thread. Following, I measured the voltage at each servo and it was over 10 volts. I disconnected the negative and signal from the BEC and voltage dropped to 5.5 (same measured at receiver). And suprisingly, the servos worked fine. However, the ground is going through the receiver, then through ESC #2 to ground to the battery so I will check and see if the BEC is still good and if so, ground both servos through the BEC and leave the signal disconnected. I just hope I didn't damage the servos over the course of the 5 minute span. They didn't catch on fire but they got real hot.

|

| |  |

| | #11 |

| Tire&Foam Extraordinaire  Join Date: Jun 2007 Location: C.I. Compound, Tyler, Texas

Posts: 5,601

|

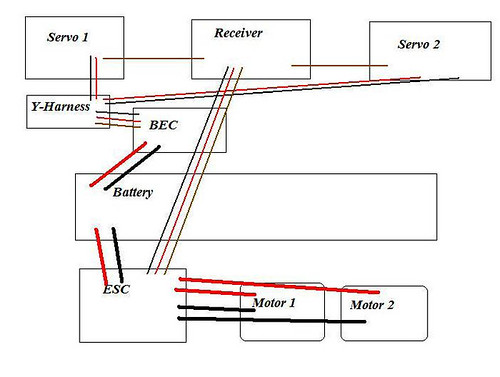

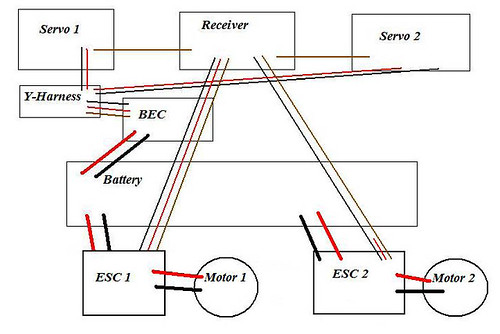

Here's how you can do it with one ESC:  Here is how I did it on my Super:  On my Super I use the BEC to power both servos. Only the signal wires from the servos go to the receiver. I use one ESC to power the receiver. On the second ESC I remove the small red wire. I am using a BR6000 receiver and a DX7 on my Super. Here's the build thread: SWuper build #2 |

| |  |

|

| |