| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Newbie Join Date: Sep 2004 Location: Lancaster

Posts: 23

|

I don't think anyone remembers, but i remember RCCA ran an article about 5 years ago on a basically full custom made crawler called "bad monkey jr." which was built by an engineer.. anyways i remember he made basically the whole truck from scatch, BUT the gear box was a collection of gears he purchased and assembled in his own aluminum housing with plexiglass cover with a 2spd range for low and high. Snooping around i found his website which contains other links including links to the bad monkey jr. Question is.... since his gearbox was made by readily purchased gears, then its pretty possible to build your own gearbox with any ratio you'd like.... wonder how much it'll cost though. Opinions? http://www.marksmark.net/links.htm#mysites http://www.rccaraction.com/articles/bad_monkey.asp |

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Oct 2005 Location: deerisland

Posts: 27

|

my crawler is going to have a shiny new tranny courtasy of some rrp gears to replace the maxx trans that now resides in it. it would have it now but there was some ugliness with time and cash gods so maxx for now |

| |  |

| | #3 |

| Rock Crawler Join Date: Dec 2004 Location: www.ORCRC.com

Posts: 693

|

Did anyone notice the specs on it... Length: 18 in. Width: 141/4 in. Wheelbase: 131/2 in. Weight: 19.25 lb. Design time: 300 hours Machining time: 330 hours Suspension travel: 2 in. Motors: 2 Trinity 17-turn Sapphire Radio: Futaba Magnum FP-3PJ PCM Servos: 2 Futaba S9204 ESC: Tekin 420-G2 Battey: 6-cell Sanyo 4400mAh D-cell saddle pack Total cost: approximately $4,200 for materials, components, electronics and plating. Total time to build: one year from inspiration to completion. Mark had the design and prints done in February and started to cut metal on February 20, 1999 (his 29th birthday). The design evolved, and Mark made some changes after the first test drive on September 14, 1999. The original design had a single steering servo. 19.25 pounds and only a 13 1/2" WB - dang thats freak'n heavy!!! |

| |  |

| | #4 |

| Rock Crawler Join Date: Apr 2004 Location: Longmont, CO

Posts: 901

|

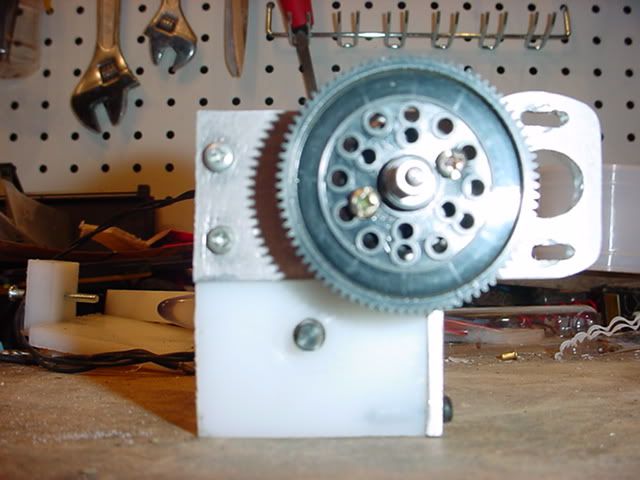

Yep it can be done. Just a gearbox check out this thread: transmission project... CAD to CNC Here's some pics of the crawler I build. The new trannys will replace the original: |

| |  |

| | #5 |

| Newbie Join Date: Nov 2005 Location: Walla Walla

Posts: 20

|

I'll be building my own tranny soon for my crawler project. I have it designed and will start cutting metal soon. I almost have my axles done and the tranny is next on the to do list. I'll post pics when it's done. |

| |  |

| | #6 |

| Rock Crawler Join Date: May 2005 Location: omaha

Posts: 858

|

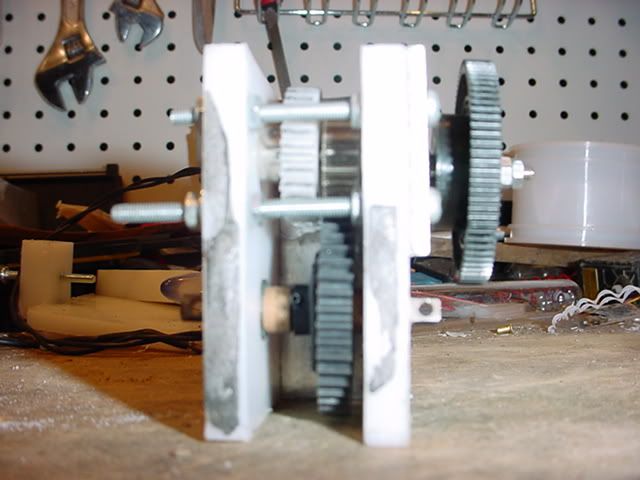

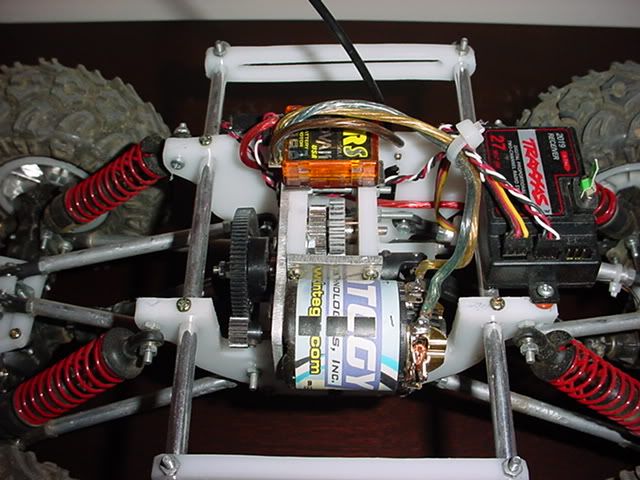

I have built a couple of trans for my crawlers, it isn't really that hard. These are some pics of my TLT trans. It is a lot more compact then a pede trans, and it weights less. All the parts are from the LHS.   This is it in my TLT.  Works great, plus, look at the same chassis with a pede in it.  |

| |  |

| | #7 |

| Rock Crawler Join Date: Sep 2004 Location: a place of settlement, activity, or residence.

Posts: 842

|

Some handy info I got from a book called Tabletop Machining used for calculating distances between gear centers. 24 pitch gears 30 tooth 20 tooth 30 + 20 = 50 =1.0417 2 x 24 48 If you've got a set of dial calipers and a drill press you're good to go. It doesn't take alot of fancy tools to do something like this. |

| |  |

| | #8 | |

| Rock Stacker Join Date: Oct 2005 Location: Newbie general!!!

Posts: 89

| Quote:

And 2 in. of suspension travel???????????????? But its great, besides from the cost, unless his including the price of his lathe in there | |

| |  |

| | #9 |

| Quarry Creeper Join Date: Apr 2005 Location: Malaysia

Posts: 374

|

Here are a few more homebrew center trannies by RCC members I came across... Azvader's (Project Bula Buster) Ecameron's (New gears in stock TLT tranny!) Davkin's (TLT Rock Buggy, lots and lots of pics, 56K beware) and those helped me to build mine - (Project SLT-1). Mine's not tested yet as I'm still working on my first crawler. |

| |  |

| | #10 | |

| Pebble Pounder Join Date: Sep 2005 Location: Rapid City

Posts: 156

| Quote:

And the spec for wheelbase can't be right, because the total length says 18. | |

| |  |

| | #11 |

| Pebble Pounder Join Date: Apr 2004 Location: Calgary Canada

Posts: 138

|

RD400 can you tell me what parts you used to build your trans? it looks like a really good design.

|

| |  |

| | #12 |

| I wanna be Dave Join Date: Jun 2004 Location: Centennial, CO

Posts: 2,129

|

When I built this mini tranny for an OLD project I hotglued the gears in place, then drilled down through center of each gear with a drill press. Mesh was just right.   Talk about some jerry rigging there. |

| |  |

|

| |