| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

I've run in to an issue, I think I'm getting close to working through all the bugs that came with the truck I bought but not sure what to do atm. I thought my motor was burnt up or ruined in some way, my HH motor. So I took it off and put the axial 27T back on it. I'm running a HH BRXL esc, ax3 receiver and radio. Metal gears in trans and junfac driveshafts. VP knuckles. Here is a video that is a must see of what it is doing. You will need sound, listen for the clicks.. they will be obvious. The clicks are me pulling the throttle right next to the camera and you can see the way the truck behaves. I'm losing power, a lot. It might run okay for a minute and then it starts stuttering, losing all power, gaining just a bit back, goes full throttle, etc. It does all of these things randomly and not in any sort of order. I have a lipo that I think is good but I am not sure. The truck has taken 3-4 big falls with the lipo in it, truck tumbling down the side of a hill. Could this cause the battery to be bad? I also have a nimh battery that is having problems as well, so I would like to think I can rule the battery out as a possible problem since both batteries are doing the same thing. This brings me to think that my HH Torquemaster might be okay as well, cause it was acting similarly. Last weekend I flopped the truck in to a creek, completely submerging it. The only thing I can think of that isn't waterproof is the receiver. Truck died on impact of the water. Was a foolish mistake by me. Hours later when I got home I hooked up the receiver and it was working again. Could it be going bad from that spill? Could the motor have collected dirt/mud and need to be cleaned out? What's the best way to do that? How do I take the axial 27T apart? Could this be axle related? My driveshafts are at quite a big angle, I'm going to be lowering them asap but atm I just can't. Could this be causing a problem in the axles? Any pictures you may need to help just let me know and thanks in advance  Last edited by aebstract; 08-08-2012 at 03:44 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Jun 2011 Location: Lindsborg

Posts: 1,708

|

i would say your RX is hosed, looks like you still have steering even when the throttle is dead. it's not the battery, could maybe be a dirty throttle POT in the TX, bu i am going to put my money on the RX.

|

| |  |

| | #3 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

This problem seemed to be happening before when I was on my ax1 rx/tx and then I got the ax3 from a buddy at work. I want to just say it's the receiver but before I go buying all new parts in every location I wanted to check and see if something else could be causing this and see if there were some things I could/should try first to try and figure this out.

|

| |  |

| | #4 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

|

I would start by putting the RX & ESC in a covered bowl of uncooked rice for a few days to draw out any moisture. Then check again. Make sure you calibrate the ESC to the RX. To clean the motor, running water through it will remove dirt, blow it out with compressed air to dry it. Relube motor bearings. Look at the comm, it should be smooth with a "new penny" color. Maybe due for a comm cut. Make sure the brushes slide freely in the brush hoods, you can just grab them by the brush braid to check. Edit, looks like a sealed can motor, can't really check brushes. What battery & motor connectors? If Tamiya on the battery & bullets on the motor, that could be your issue. Most use Deans on the battery, direct solder to the motor. Last edited by Charlie-III; 08-09-2012 at 06:24 AM. |

| |  |

| | #5 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

I had my ESC waterproofed so it should be okay, I can try and pull any moisture out of it though as a safety, but it should be good. I had taken the HH motor apart and looked at the inside parts and it all appeared good to me. Then I went to try and take apart the axial and couldn't figure it out, being a solid can makes sense in this case. :P I'll clean the motor out tonight. I'm using traxxas connectors for the battery and I have a wire soldered to the motor with a bullet plug soldered to the wires which plug in to the female bullets that come on the brxl. When I get home from work today I will take pictures of various things, the way the motor connects to the brxl being one. The tabs that you solder to on the motor were really weak, as in they were bent down and whatnot from where they normally would stick out. This was the motor that came with the rig when I got it, and just about everything I got from this guy was a mess. I would love if my HH motor was good, so I'm going to tear it down again and take pictures of everything on it to see if it looks good or not and possibly give it another try. Thanks for the comments so far, hopefully we can get to the bottom of this mess! I'm soooo ready to drive this truck for a full lipo battery and not have it break down. :( |

| |  |

| | #6 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

Also I want to add that it only does this with pressure applied. If I pick the truck up or flip it over so that there isn't any pressure on the wheels/drivetrain then it spins/accelerates normal and freely.

|

| |  |

| | #7 | |

| RCC Addict Join Date: Jul 2009 Location: Dover, NH

Posts: 1,153

| Quote:

I am thinking a good possability of an issue will be in the soldered on bullet connectors where they plug into the HH BRXL. The ones for the motor. It is hard to solder that kind of connection. And you probably kept that part in place when you swapped motors and just resoldered the wires at the motor side when changing motors. So if there was an issue at the bullet connectors it would follow between motors. I would see if you could re solder the connection or replace it if necessary. I have had that issue before. Even the solder joint may be good but just after the bullet connection the wires can tear from bending or wear. It may even look tight but be a "cold" solder joint. That means there is solder in the connection but it just filled the joint without making a good connection between the two pieces. If you pull the bullet connectors out of the HH BRXL be carefull. The posts can break off the BRXL as the bullets fit in pretty tight. Happened to my Bud. My BRXL does not have those right on the esc, but rather pigtails that come out of the esc. He changed the design at some point. Not sure if mine is a newer or older style, but anyways. Be carefull pulling out the bullets. Try and re solder them and then see if it works. The issue you are having can be similar to a car battery. it can show sufficient voltage if you put a meter on it (about 12 volts in this case). But when you try and start the car it will not turn the starter well. That is because the battery can not produce the amperage needed for a high drain starter. This will show if you do a load test on the battery. You put a load on it and the voltage drops way down. In your case you have tried multiple batteries. So we can "probably rule out your rc batteries having the issue with not being able to produce enough amperage (the real working force similar to torque in an engine for lack of a better explanation). I am thinking the connection between the esc and the motor is at fault somewhere with what you have listed. 1. tried different batteries (rules out amperage draw problems or the batteries connector). You may have a bad connector where the batteries plug into the esc. 2. Tried different motors (rules out mostly motor issues such as worn brushes, etc) Though you may have 2 worn out motors, unlikely I think to both be in the same state of wear to give intermittent performance but still a possibility. 3. tried different radios (rules out transmitter receiver issues or lack of signal). So I think most likely esc to motor connection. The connection that has stayed the same between motor changes is the connection of the motor at the esc (where the bullet connectors are). And as a second main possablillity is the connector where your batteries plug into the esc. Good luck! Last edited by Rook82; 08-09-2012 at 04:26 PM. | |

| |  |

| | #8 |

| Rock Crawler Join Date: Dec 2011 Location: thurmont

Posts: 732

|

same thing with my mrc. i guess i just need to upgrade the rx/tx

|

| |  |

| | #9 | |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

| Quote:

| |

| |  |

| | #10 |

| RCC Addict Join Date: Oct 2008 Location: south caki laki again

Posts: 1,695

|

it appears either the receiver or the esc is trying to thermal overload and shut down, this would explain it working fine when no load applied, do you have a bec in the system? If not what do you have the bec voltage on the brxl set to? Last edited by hbj069; 08-10-2012 at 06:26 AM. |

| |  |

| | #11 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

As to removing "bullet connectors", I'm NOT talking about the connectors on the ESC, I'm talking about possibly cheap ones used to connect the motor. These are more common on some cheaper RTR's, the ones on a BRXL (for example) are great, no issues there. Traxxas connectors for the battery pack should be fine as well if the solder joints are good. | |

| |  |

| | #12 |

| Rock Crawler Join Date: Oct 2011 Location: Great Outdoors

Posts: 651

|

My 2 cents is troubleshooting analysis is overrated. Look at how many divergent opinions you get just on this thread. My caveman technique is to methodically replace the electronics with spares until I locate the troublemaker. But if you're not even sure it's in the electronics, this would probably also be a good time to inspect the bearings and grease the gears. Never know what you might discover in there. . Last edited by Hardline; 08-10-2012 at 09:04 AM. |

| |  |

| | #13 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

I have it sorta easy, I have multiple radios, motors, batteries, ESC's, servos, BEC's, etc. I still prefer to at least narrow down the potential issue before swapping stuff. If you just "parts swap", you sometimes add issues while trying to find the original issue. | |

| |  |

| | #14 | |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

| Quote:

For instance: if I try both batteries and the problem is still happening, my batteries might both be bad.. it's a possibility under the circumstances. Though, it could be the connection to the motor and both batteries might be good. This same example can be applied to each part. I just got the BRXL from warranty replacement and waterproofed, I know it is good. So that's a good start. I don't have a bec, but I also don't need one with the BRXL, correct? How do you set the "bec voltage" on the brxl? I haven't seen an option to set that. I have a friend I work with that is going to bring me a battery, charged and good to go on Monday. I'll be able to guarantee the battery is okay when I try it. I wasn't looking for anyone's opinion on the actual thread, while the answers may be very far off.. the issue could potentially be any of these things and it'll help give me options of what to look at and try. I like to think I'm a pretty smart guy and have enough common sense to try a different part if I have it. Last edited by aebstract; 08-10-2012 at 10:44 AM. | |

| |  |

| | #15 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

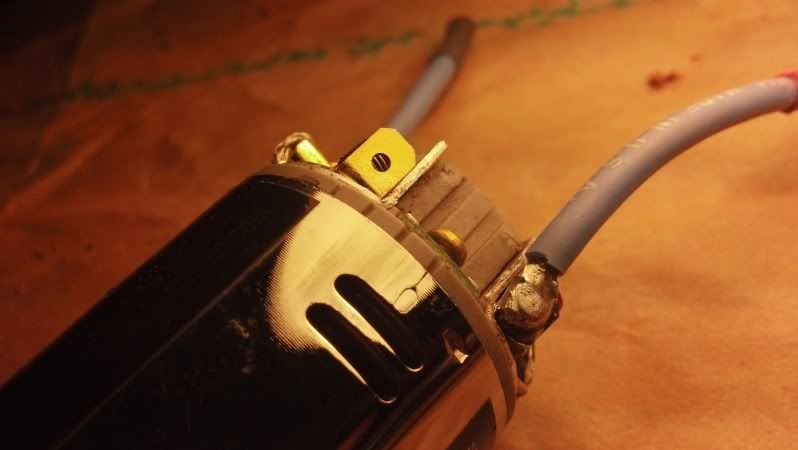

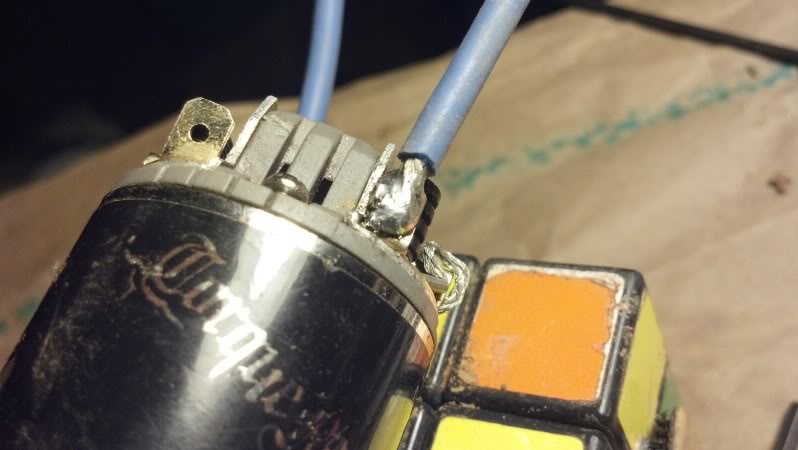

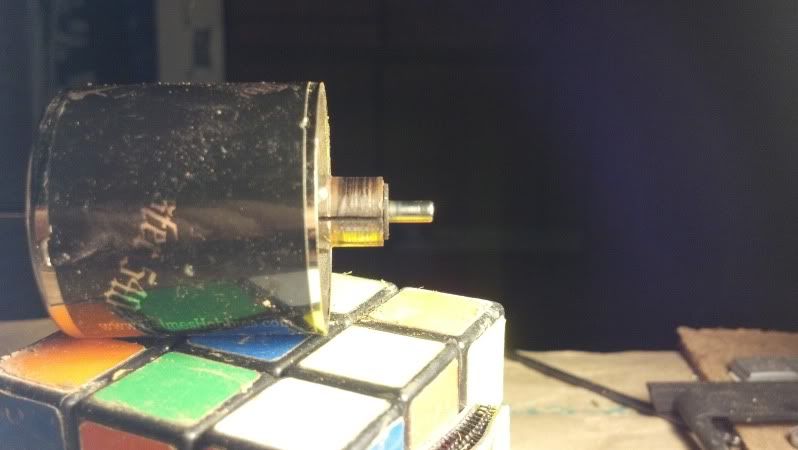

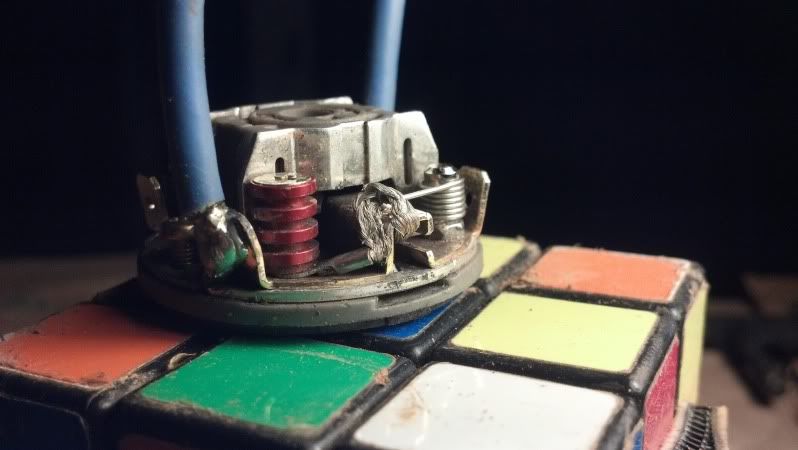

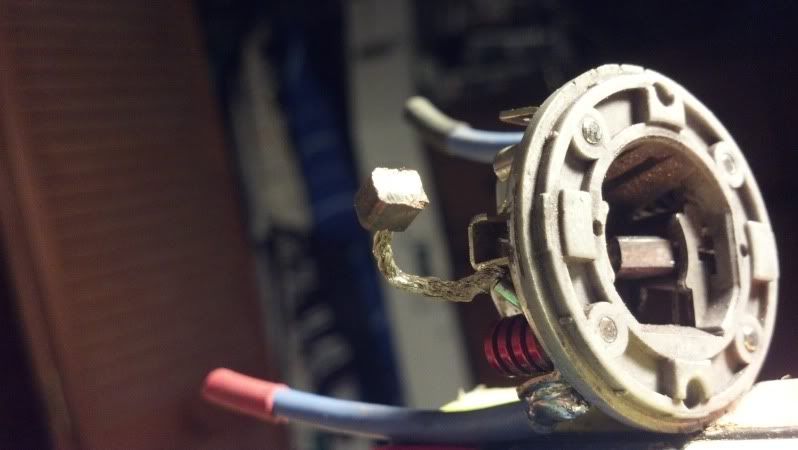

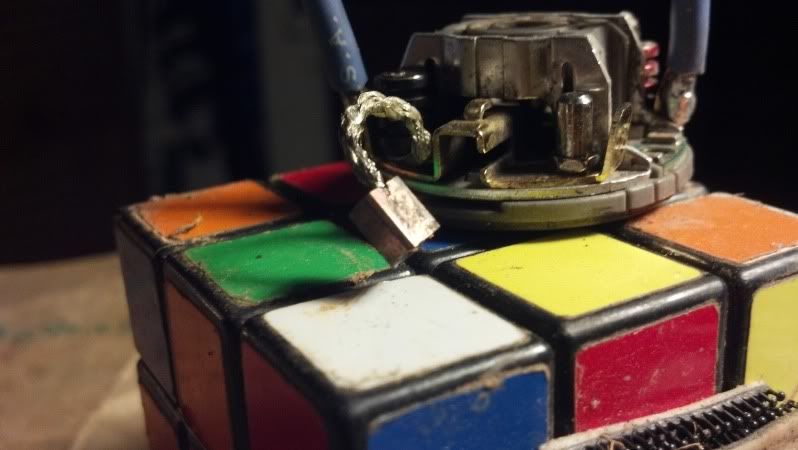

Okay, first round of pictures are here for today. These are of the motor that I believe is bad. This sets it to 0? This is correct, right?  Solder   arm   comm     Other comm   |

| |  |

| | #16 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

|

Solder joints look "OK". What you call the "arm" also has the "comm" on it. It could use a light skim cut (but it's not awful) on the comm (the copper segments). What you call the "comm" is actually a brush. One is shot, the other is close to being shot. I would guess that on one of the brushes (when the motor is assembled) the brush spring is at/close to the bottom of the spring slot. I would replace both of the brushes. |

| |  |

| | #17 |

| Rock Stacker Join Date: Jun 2012 Location: Cleveland

Posts: 67

|

Okay so I won't need to actually send the motor in for a repair, I can just order some brushes and swap them out? That'll be nice. I'll start some more in depth troubleshooting tomorrow since I'll be off work.

|

| |  |

| | #18 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

| |

| |  |

| | #19 |

| Rock Crawler Join Date: May 2011 Location: SoCal

Posts: 949

| |

| |  |

| | #20 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote: I would NOT suggest using the sandpaper method though. Yes, the comm will be shiney, but likely not round or concentric. Also, don't use water breakin. | |

| |  |

|

Need help diagnosing an issue - Similar Threads

Need help diagnosing an issue - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| MMP issue... i think i'm the issue. | concretejungle | Electronics | 12 | 08-13-2012 02:52 PM |

| need some help diagnosing this electrical issue - VIDEO | iamsuperbleeder | Electronics | 15 | 09-17-2011 10:08 AM |

| has anyone else had this issue? | up-n'-ova | Losi Mini-Rock Crawler | 19 | 03-06-2009 04:08 PM |

| Serious Issue | rockrunner | General Crawlers | 7 | 08-23-2006 03:05 AM |

| Anybody else have this issue | Gula | Comments, Suggestions, and Help | 1 | 07-21-2006 05:25 AM |

| |