| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

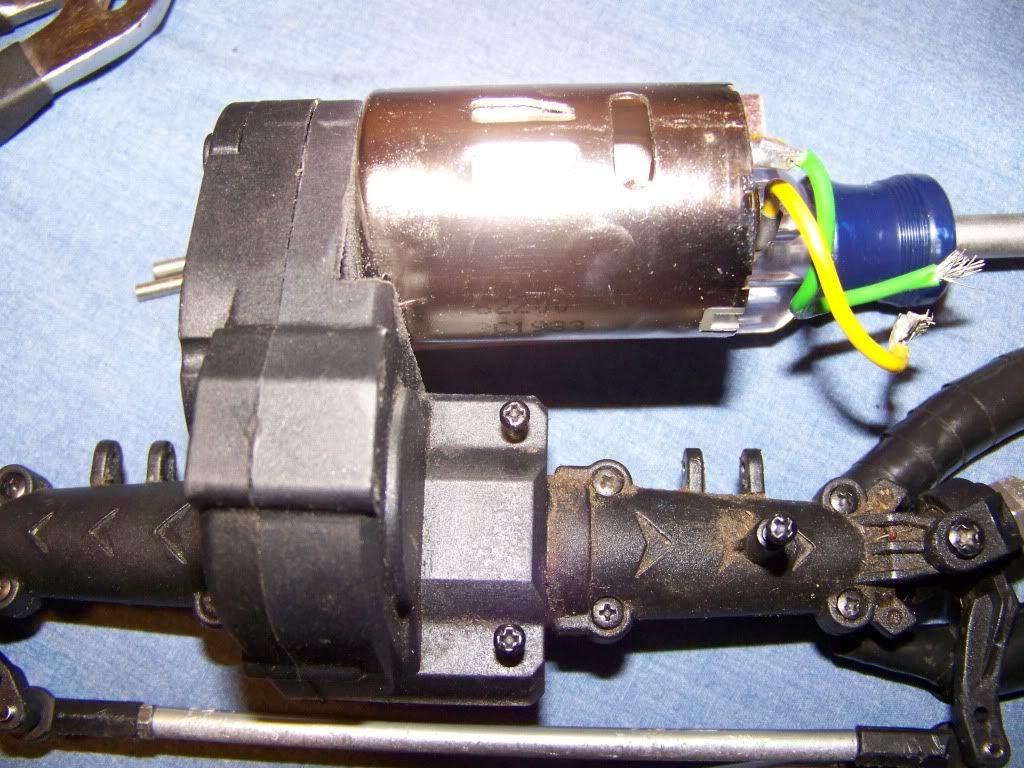

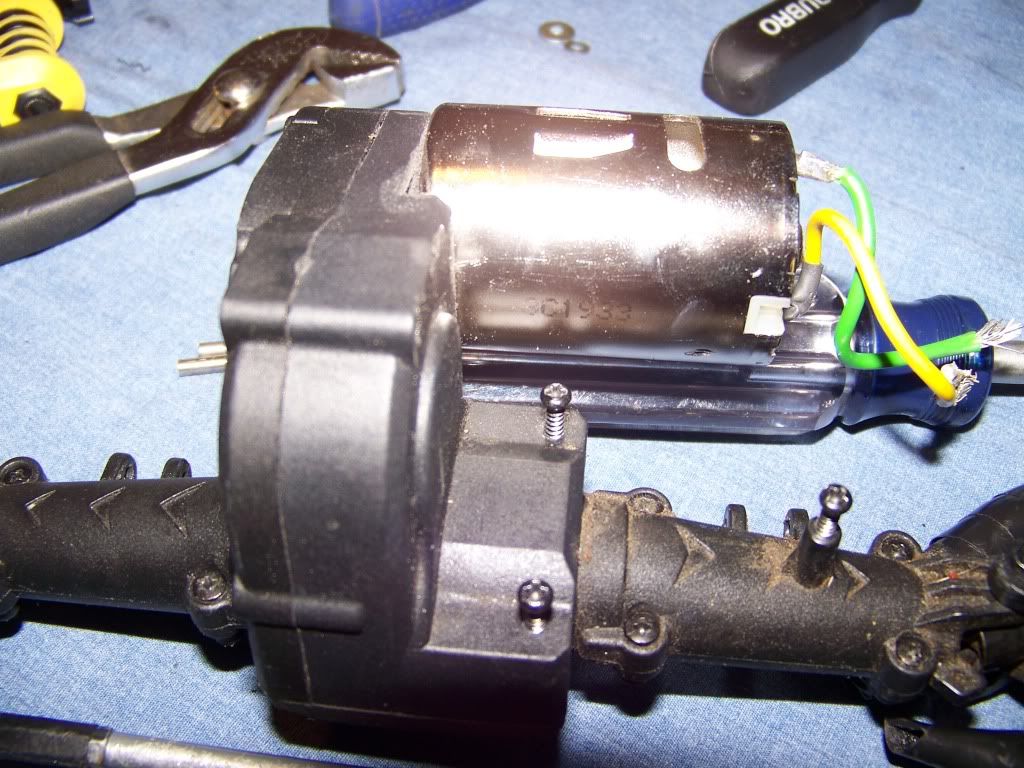

alright, well i have decided to try the 540's in my rig. i was running 390 12v banebots. they work very well for the rs10, but it was still lacking that grunt. my current setup consists of a sidewinder, 3 cell 1000mah lipo. as well as a bec. thats pretty much it power wise. i have just recently finished the fabricating. i have 45t motors on order and are on their way to me as i speak. the motors in the pics are mock up only. there has been quite a bit of discussion about 540's and i have read some about wanting to know how. so with that said i took pics as i modified the axles for 540's. keep in mind that everybody has different ways of doing it. this is more less to show what is basically involved in it. okay, well on with the pics!  sorry for the blurry pic. this is a comparison between the 540 to the 390 banebots i was using. not to much different other then diameter. the 390's are pretty long. 540's are just a tad longer but not by much.  okay first thing to do is dismantle your axle. after to make room it will involve cutting. you can see where the hole is for the pin that holds the first gear in place. do not cut past this other wise it may cause issues. mine is still together and not separated.i cut enough to allow adjustment for the motor.  after cutting i took some time to make a cardboard template. i then bent some aluminum to cover the exposed areas from cutting as well as aid some strengthening. with 540's in here im sure there will be a need to beef up the area. redcat designed these for 380's. i would rather go over kill then be sorry later.  okay next up is to shorten the shaft for the first gear. since cuttling the housing the shaft will stick out. in the pic you can see how far i cut into where the shaft sits. i drilled holes into the aluminum and ran 4-40 bolts through for strengthening and to hold the piece to the housing. i left some of the bolts long. i did this because i fiberglassed inside the case and doing this will make the hold much stronger and add more strength to the case. i made room for adjustment as well. so this should be able to work with pinions ranging from 8-14 tooth pinions.  okay i got my woven mat cut up and ready to go. i used the mat because its much stronger then just the cloth. all there is to do is mix up a batch of resin and start glassing.  okay its hardened up and ready. all cleaned up. i layed the mat down to patch the holes and build up around the slot for the pin. this are will need to be strengthened from cutting. if you go as far as i did this will be a must. with more power and plastic gears, you do not want any chance of slop or play to eat the gears.  alright motors in. i put some washers on the bolts to help displace more pressure on the housing to hold the bigger motors.  the finished product. axle ready to rock with 540's! well when they come in anyways. hope this will help any one who would like to do this, but does not know how to go about it. i used basic tools. not to hard anyways. like i said things can be done differently so if you decide to do it, you dont have to do it the way i did.good luck, hope this helps    |

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Nov 2009 Location: Asheville, NC

Posts: 39

|

This is a great write up. Really helps alot, Thanks! |

| |  |

| | #3 |

| Quarry Creeper Join Date: Nov 2009 Location: gilbert az

Posts: 199

|

I really like the aluminum cover idea. Good job!!!  Jake Last edited by jr104; 05-22-2010 at 05:28 AM. |

| |  |

| | #4 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

thanks guys, i have been wanting to do it for a while now. i tried to make it as clean as possible. my banebots worked really well, but i still had a bit to much stall when ever i would climb some big steep stuff. i know two esc's is the way to go, but i like the stall. ill take the stall any day of the week over tt. i only ran shaftys before this rig. my housings now feel very strong, so im not worried about the motors moving around or out of place to chew up gears. im sure it will happen, but it wont be from that. like i said this isnt the way you must do it. im sure there is other good ways, maybe better then i did. i just wanted to post a thread showing whats basically involved, so whoever is wanting to has a good general idea of what it takes. i know there has been some questions about how to go about it.

|

| |  |

| | #5 |

| Pebble Pounder Join Date: May 2010 Location: Central Coast

Posts: 111

|

I wonder if that aluminum will help dissipate heat as well?

|

| |  |

| | #6 |

| Pebble Pounder Join Date: Jan 2010 Location: Vancouver

Posts: 165

|

Man!You are way more ambitious than i am!Nice job.

|

| |  |

| | #7 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

| haha, ambitious  im probably the biggest procrastinator there is. i had been wanting to do it for a while. it came together pretty easy, but then again i had alot of time to think about how i wanted to do it. i just posted it up because i know i have seen a couple threads wanting to know whats involved in it. so i took some pics as i did it with out the hack the case, stuff the motor in and hope the gears hold up line. just trying to help pay it forward. as long as it helps at least one person do it that wasnt sure about it im happy. i was actually surprised that no one else posted how they did it. im probably the biggest procrastinator there is. i had been wanting to do it for a while. it came together pretty easy, but then again i had alot of time to think about how i wanted to do it. i just posted it up because i know i have seen a couple threads wanting to know whats involved in it. so i took some pics as i did it with out the hack the case, stuff the motor in and hope the gears hold up line. just trying to help pay it forward. as long as it helps at least one person do it that wasnt sure about it im happy. i was actually surprised that no one else posted how they did it.

|

| |  |

| | #8 |

| Quarry Creeper Join Date: Nov 2009 Location: gilbert az

Posts: 199

| |

| |  |

| | #9 |

| Pebble Pounder Join Date: Apr 2010 Location: Brighton, MI

Posts: 175

|

So I ordered up a set of extra housings to chop up to do this. That way if I screw it up I still got a good set fitted for 380s. Now I just gotta get motors. Any body used the Holmes slow motors that are $6 each http://holmeshobbies.com/product.php...&cat=17&page=1 . I know they won't be comp worthy, but they should be better than these 380's

|

| |  |

| | #10 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

So i have and update with the 540's. the plastic gears held up very well.i was very worried about the durability of the gears.i got it bound up a couple times and the tires were twisted up on the wheel. i ordered two 45turns. i only received one of them, so i had an old 35 turn that i tossed in the front for now. i went down to my lhs and the smallest gear i could get was a 16tooth in the correct pitch. i didnt set the mesh tight. i meshed it slightly snug, but not enough to create any drag. there was no need to have a tight gear mesh. i made some clear gear covers so i could keep an eye on the mesh. no issues at all.the mesh stayed right where i left it. i did have quite a bit of stall, less then the banebots i was running. but that was due to the pinions.very crawl able. you want to see a fast rs10. holly smokes. i though the wheel speed was good with the banebots. enough wheel speed to do some drifting around on the tile at the lhs indoor coarse. i was tempted to run it on their carpet track. and when in the loose stuff a quick jab of the throttle and you have roosters flying from all four wheels. if it wont crawl it.it will jump it  . i only lost about 20 minutes of run time. still get a good hour. the time and effort to put 540's in was welll worth it. very pleased.all the power and speed you will ever need or want im sure. cant wait til i have metal gears in it. the only time i babied it was when a tire was really bound up in the rocks . i really love the wheel speed. i would like to go down to a 12 tooth pinion. it was the first time my buddy saw it in action. needless to say he wants to go moa now. he was very impressed with its performance. . i only lost about 20 minutes of run time. still get a good hour. the time and effort to put 540's in was welll worth it. very pleased.all the power and speed you will ever need or want im sure. cant wait til i have metal gears in it. the only time i babied it was when a tire was really bound up in the rocks . i really love the wheel speed. i would like to go down to a 12 tooth pinion. it was the first time my buddy saw it in action. needless to say he wants to go moa now. he was very impressed with its performance. |

| |  |

| | #11 | |

| Quarry Creeper Join Date: Nov 2009 Location: gilbert az

Posts: 199

| Quote:

I'm running 13T in the front w/12 in the back now with the 35T's . I reaally like this gearing  . better than 12T and 12T . better than 12T and 12TI almost got my Son covinced to come over to MOA Jake | |

| |  |

| | #12 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

i wish i would've done it a long time ago. there was one time it started to go roll over backwards. i can always save it with a quick reverse. well i recovered it and did a reverse wheelie and landed on the lid on a rock wall climb. it takes some getting used to the power. ill have to see if i can get some video of it. one of the guys down the shop told me that it was way to fast for a crawler. it has plenty of slow speed control though and no power issues. can wait til i get the other 45t though. i love this thing!

|

| |  |

| | #13 | |

| Quarry Creeper Join Date: Nov 2009 Location: gilbert az

Posts: 199

| Quote:

| |

| |  |

| | #14 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

| http://s780.photobucket.com/albums/y...5-30222009.flv well got a small video. had to have my wife do it because i didnt know how to go about uploading video |

| |  |

| | #15 |

| Pebble Pounder Join Date: Mar 2010 Location: high planes desert

Posts: 140

|

bump

|

| |  |

| | #16 |

| Pebble Pounder Join Date: Apr 2010 Location: surrey bc

Posts: 111

|

That is AWSOME!!!! nice job!!..so i was talking with ZNO the other day when i ordered a new spur gear assembley and he was tellin me that there coming out with a new axel for the 10 that will fit the 540's!!!!!!!!!I sure hope this happens just like all of us here lol!!! Please do it up for us ZNO!!

|

| |  |

| | #17 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

that would be awesome. i havent had any issues with mine modded anyways. zno's trying really hard to make the rs10 more noticeable. he see what we all do in them. i though about buying housings and offsetting them with 540's for better link clearances, but if i did i would lose my battery spot, so ill stick with what i got.

|

| |  |

| | #18 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

How long are your 540 motors? I am doing the swap right now. I have the motors mocked up and they look like they will block my tabs for my links. I'm using the motors from my TXT-1 and they are two inches long. Any tips would be helpful. I always try to include a couple pictures.    |

| |  |

| | #19 |

| Rock Crawler Join Date: Jul 2009 Location: waterville

Posts: 525

|

i have my links on the outside of the link mounts. they have mild bends to give the motors a little more clearance. mine are also bent links as well. straight links will probably require less bending. i also have a 2'' wide chassis. so bending also depends on the width of your chassis. the motors i am running now are the same dimensions. i would think a rebuild able motor would aid in link clearance as well.

|

| |  |

| | #20 |

| Quarry Creeper Join Date: Jul 2010 Location: Independence

Posts: 368

|

well just got my 540 mod done battery charging getting ready to take it out. got some 55t rc4wd to try. i used a hole saw to mod the gear case to give it that curved factory look. big mistake. should have just cut it straight like jwo. by cutting in in circle had to fiberglass alot of stuff that is now showing and not hidden behind aluminum. try to bend the aluminum but you need to be a metal fab dude to do what i need. so mine are just reinforced with fiberglass cloth and resin. should work though. ordered steel gears today and hardened pins just in case. plan on tearing something up. proll esc will go first though. motors really hit shocks bad. gonna have to do something about that. prolly swap shocks and links around. but then the shocks would hit tires more so not sure yet.

|

| |  |

|

| |