| | #1 |

| Newbie Join Date: Jul 2006 Location: taftville

Posts: 12

|

Okay so here goes the probs with my TXT.. Just swapped in a 55 turn integy lathe motor, stock pinion, and an LRP AI Runner with reverse speed control. The truck is gutless. It came with some capacitors i think in the speed control box. I didnt put those on yet but i can reach down and grab the truck with two fingers and the lathe stalls and just whines. I check polarity and i think i got it right, tried switching around just in case but no good. I am waiting for my gd 600 in the mail and debating on a magnetic mayhem with a 9 tooth but not sure yet. Is it the speed control? or is the lathe motor that gutless.. HELP!!!!!!!!!!!!!!!!!!!!!

|

| |  |

| Sponsored Links | |

| | #2 | |

| I wanna be Dave Join Date: Apr 2006 Location: FLAGSTAFF

Posts: 3,728

| Quote:

put on the caps..........they come in the package for a reason........you will aslo need to go down in pinion size to as small as you can get! | |

| |  |

| | #3 |

| Quarry Creeper Join Date: Jun 2005 Location: Flagstaff

Posts: 318

|

The GD600 also helps alot.

|

| |  |

| | #4 |

| Rock Crawler Join Date: Jan 2006 Location: In the basement

Posts: 929

|

Is your battery fully charged?

|

| |  |

| | #5 |

| Newbie Join Date: Jul 2006 Location: taftville

Posts: 12

|

The batts are at full charge, brand new venom 3600 nickel metals..Do you guys think the caps will casue that much loss in power? Also, whats the best solder to use for the motor?

|

| |  |

| | #6 |

| Rock Crawler Join Date: Aug 2005 Location: White Lake

Posts: 764

|

What type of battery plugs are you running?

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Feb 2006 Location: Angier N.C.

Posts: 387

|

You said you are running a LRP Runner? Are you running 2 servos? Are you running a reciever pack? I asking cause If you are not running a reciever pack and are running 2 servos, your robbing your motor of power. LRP reverseable runner has a BEC rating of 5 volts. The ideal would be a esc with a rating of 6 volts BEC. Like the Tekin rebel 2 or Super Rooster. Try a reciever pack and don't turn the esc on. Just let the reciever pack power the esc. I have a LRP f1 bullet, had the exact same problem. Plugged in an rx pack and it fixed my problem anyways. But then again, I had to run the rx pack and switch the esc on. AND definately change that pinion. Stock TXT pinion is what 15 tooth? find you a 10, 9, or 8 tooth and you will see some major differences.

|

| |  |

| | #8 |

| Rock Crawler Join Date: May 2005 Location: omaha

Posts: 858

|

Big truck + large tires + 7.2 volts + 1 55 turn lathe motor + stock gearing ---------------------- Gutless crawler. You will need to do a couple of things... 1. Gear it correctly, 9 tooth pinions 2. If you TXT is running anything bigger then a 2.2 setup, you need 2 55T lathe motors. 3. If you want to run 1 motor, you will need a GD600, 8 to 10 cells, and a new ESC. These are a couple of things that will help. You have to remember, a TXT is much heavier then most tlts. Your motor/battery/ESC combo is more of a TLT setup. In my TXT I run a MM on a 2.5 to 1 reduction with a TR2 and 6 cell pack. |

| |  |

| | #9 |

| Newbie Join Date: Jul 2006 Location: taftville

Posts: 12

|

Okay so i just bought a 9 tooth and a 12 tooth pinion ofr the gd 600.. Hopefully that will help alot.. As far as speed control i am going to try and make it work i guess. That thing was 50 bucks.. Whats the best motor for a crawler in you guys opinion? I heard the 55 turn lathe was good? Thanks for all the help too..

|

| |  |

| | #10 |

| Rock Crawler Join Date: May 2005 Location: omaha

Posts: 858

|

55T lathes are great, you just need to run 2 of them in a TXT on 6 cells. Your ESC will handle 2 lathe motors without a problem. Give 2 55T's with 9 tooth pinions and I bet you will be more then happy with the results |

| |  |

| | #11 |

| Rock Stacker Join Date: Nov 2005 Location: Bangkok,Thailand

Posts: 65

|

I agree with hvydty1 and try to set a ESC once again.

|

| |  |

| | #12 | |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| Quote:

Two stock motors, or two 35 turn motors in series and small pinions are really sweet. Last edited by EeePee; 10-09-2006 at 08:37 PM. | |

| |  |

| | #13 |

| Rock Crawler Join Date: May 2005 Location: omaha

Posts: 858

|

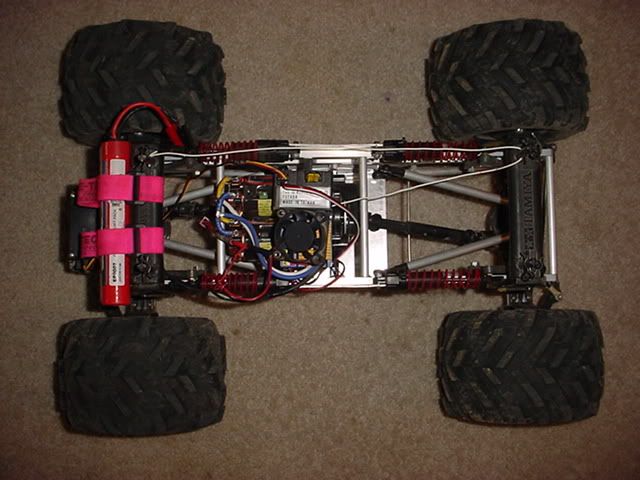

I ran mine in parallel. EeePee, I ran mine with 9 tooth pinions and silver cans back when my TXT looked like this...   You can see in the last picture, I was running 2 P2K Pros with 9 tooth pinions. I needed all that power to move that 12 pound P.O.S |

| |  |

| | #14 |

| Quarry Creeper Join Date: May 2004 Location: Hartford, Connecticut

Posts: 355

|

There is no need for dual motors or more than 6 cells in a TXT with a 55T lathe and a GD600. Get ALL of the un-necessary components and wieght out and you will be absolutely fine with a single lathe and a GD600. I am running that setup in my TXT with Moab XLs and I have no problems at all with power. On a rare occasion that my TXT does have motor stall, it's a GOOD thing. It means that there is a tire jammed or something is caught on a rock. Any more power in a situation like that will just lead to broken parts.

|

| |  |

| | #15 |

| Quarry Creeper Join Date: Feb 2006 Location: Tweaking my shaft

Posts: 278

|

^ I agree with fullmodtxt. I run 40 series Mashers with a 35T Itegy and a GD600. I have no problems with stalling, unless like fullmodtxt said, you get a tire stuck or bound up.

|

| |  |

| | #16 |

| I wanna be Dave Join Date: Nov 2005 Location: Here

Posts: 7,317

|

OK guys...on the same note. I am running a 55T Lathe with an Traxxas EVX ESC with one 7.2 and two servos. It seems like there is no power. I added a reciever pack and now the thing does not move. I can turn the steering but the truck won't go. On the 55T I am running a 9T pinion. When it goes, it will crawl vertical but only if the wall is a foot high. Should I run 14.4V...will the 55T handle that? Do I need to add a GD600? I was trying not to run two battery packs for weight. Any suggestions???? |

| |  |

| | #17 |

| Rock Crawler Join Date: Jan 2005 Location: Bethlehem, GA

Posts: 583

|

I am having the same problem with one of my crawlers. I have a rooster on a 55t lathe on a Pede tranny to TLT axles. It has 2 steering servos. It had NO power. It would roll but would not climb an obstacle. I added a GD600 and it will climb now but still not as much power as it should. Would the Rx pack make that much of a difference? Should I disconnect a servo and see if that makes a difference?

|

| |  |

| | #18 |

| Pebble Pounder Join Date: Oct 2006 Location: Knoxville

Posts: 102

|

I'm thinking about putting a 75t single lathe in my rig with a teken rebel 2. Anyone have any words of wisdom on this idea?

|

| |  |

| | #19 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

I typed out what seemed to be about an entire book for a reply to try to cover all the bases, but I scratched that and I'm posting my suggestions which are based on 7.2 volts. Adding more voltage would only improve the power and speed. These set ups are a medium walking pace. -Two stock motors in series on 9 tooths. -Two 35 turn motors in series with 13 tooths. -A stock motor and a 3.8:1 GD600 with a 15 tooth pinion inside the TXT tranny. -A 35 turn motor and a stock GD600 with a 15 tooth pinion inside the TXT tranny. Everything else is either too slow and needs to be regeared to gain back some speed, at the expense of power, or isn't powerful enough on it's own. I think that covers the motor choices, but then there's the brushless stuff... Rockcrusher90, I found the single 55 turn motor to be weak, but not as weak as you make it seem. Maybe your motor needs to be cleaned. If it's good to go, definately try more voltage, maybe 8 cells. If you add a GD600 to your current set up, there's a 2.5:1 gear reduction, which makes for a really slow truck. jwrape, try one servo, it might be the problem if the problem happens when you're turning and trying to crawl. You might be overworking your ESC's BEC. So yes, a receiver pack would help by eliminating the need for the ESC to do the work, and devote all it's power to the motor. Colorblind, in my opinion a 75 turn motor will be way too slow. Then you'll try to regear it for some speed, and you'll lose power. Pointless really. The higher wind motors aren't nessecarily more powerful, the peak of their power happens at a lower RPM. Maybe that helped? |

| |  |

| | #20 | |

| Rock Crawler Join Date: Jan 2005 Location: Bethlehem, GA

Posts: 583

| Quote:

| |

| |  |

|

| |