| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| On the lookout for Rocks  Join Date: Mar 2006 Location: Monroe, Louisiana

Posts: 3,711

| |

| |  |

| Sponsored Links | |

| | #22 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

You can get some silv and flux from RAM WELDING supplies on line. http://www.ramweldingsupply.com/ Thanks for the assistance PInk.. .. and just to add to my long reply. 1 t.o. should cover all your needs. I simply suggest 2 t.o.'s cause I know there will be screw ups and start overs or another build down the line. I can usually get 2 to 5 Tubers out of one t.o as Pink noted just depends on the build at hand. |

| |  |

| | #23 |

| I wanna be Dave Join Date: Apr 2005 Location: Vegas

Posts: 7,172

|

I picked up some rods at Home Depot. I will post a pic up of it. It was cheap and has 85,000 Psi strength. I have been having fun and made my first stinger/ bumper last weekend. I will post up a pic of that as well. |

| |  |

| | #24 |

| RCC Addict Join Date: Mar 2006 Location: MUSE, PA

Posts: 1,273

|

i would like to know if the hi-fill silver brazing alloys from mcmaster-carr work as well as harris saf-t-silv. especially considering the mcmaster stuff is less expensive....

|

| |  |

| | #25 | |

| Quarry Creeper Join Date: Apr 2005 Location: South Jersey (Cherry Hill area)

Posts: 240

| Quote:

| |

| |  |

| | #26 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

That is a super looking bumper. Nice work  |

| |  |

| | #27 |

| Rock Crawler Join Date: Jul 2005 Location: Central Coast

Posts: 667

|

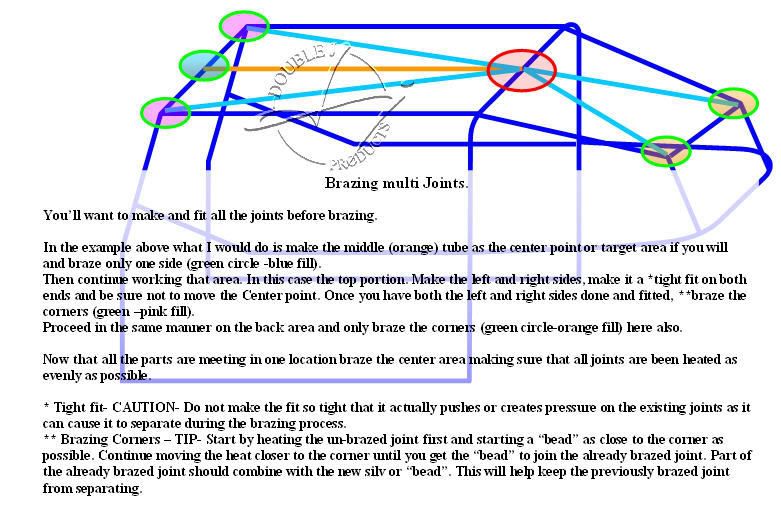

Just thought I'd ask for a couple tips here and contribute one for the next guy. I'm working on #2 as we speak and things are going well, but slow (lack of motivation, time and direction on a couple parts). How do you guys have your torch tips setup? Im asking specifically about the cone, etc. What I'd like some advice on. Whats a good way to get a NICE looking and strong joint where you have as many as 5 tubes meeting in one place? (All tubes are properly fishmouthed and fit nicely together) I can get 2 or 3, but after that, I start displacing the existing brazing and I begin getting puddles or end up with cold joints. Are you guys cleaning, fluxing and rebrazing the entire joint everytime you add a new tube? Last but not least, whats the best way to braze thin gauge sheet metal onto 3/16" tube? I've not tried this yet, but I assume you just preheat the tubing and concentrate the heat on the tube primarily? The idea here is the front skid/ winch plate as well as the the two boatside plates underneath next to the skid plate (Poison Spyder style Bruisers, etc). So if the sheet starts to warp its going to be problematic getting the other sides in the correct position. A tip I have for some other people, try putting a LITTLE flux inside of the tip of the tube you are brazing, it seems to help pull a little bit of brazing rod inside the tube so it effectively brazes the joint inside and out.  |

| |  |

| | #28 | |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| Quote:

Hope this helps with the 2nd part of your question.  | |

| |  |

| | #29 |

| Quarry Creeper  Join Date: Sep 2007 Location: Middle of the USA

Posts: 321

|

If anyone is interested in a good brazing rod or paste I have been in the welding supply business for years. Harris Welco makes a dam good brazing rod that is a 45T. The melting point is around 1100 deg. This is around 300 to 400 deg lower than most. Teh flow of the puddle is much nicer, and you risk less warpage and metal fatigue with lower melting points. Just Pm me for pricing, and I also have great deals on jewler torches, victor or smith.

|

| |  |

| | #30 |

| I wanna be Dave Join Date: Apr 2005 Location: Vegas

Posts: 7,172

|

Brazolene is the brand. They are really easy to use and the joints are really strong.

|

| |  |

| | #31 |

| I wanna be Dave Join Date: Apr 2007 Location: clarksburg

Posts: 2,009

|

How about some strength comperison ,Like taking a flat piece of stock and brazing it to another in a T shape then put the pressure to it with a hydrolic jack of some sort and seeing how much it takes to fail. you could do mig weld ,tig,braze,solder,,you get the point. I have always mig welded and wasnt sure of the silver solders ability to handle a 12 to 16lb rig.... And this is a great idea you have man.I hope it works out well.....Thanks for listening!!! |

| |  |

| | #32 |

| Quarry Creeper  Join Date: Sep 2007 Location: Middle of the USA

Posts: 321

|

rc jeep if you look at tensile strength, tig welding is obviuosly your best bet. Welding and brazing have similiar strenghts. I know a 70S-6 wire can range from 65,000 to 80,000 and a good brazing rod has the same capabilities. Now if your looking for a stronger weld you need to focus on metal core and flux cored wires.

|

| |  |

| | #33 | |

| Rock Crawler  Join Date: Jan 2008 Location: Jonesboro, Arkansas

Posts: 879

| Quote:

| |

| |  |

| | #34 |

| RCC Addict Join Date: Apr 2005 Location: Seattle

Posts: 1,437

|

Nice thread Jason. I will poke my head in here as well. I like the start to finish vid, I may try to work on something like that as well, different techniques I am sure, and vid is the best way to show it all. I use 45 and 56, whatever I can get cheapest. There has been some talk about strength, but with what we are doing, it's all irrelevant, we don't need 80,000 psi joints, lol. Multiple tubes meeting at one place. I mostly run into this with the triangulation supports across the top of a roof. As much as possible, I braze the other ends of the tube first, along with tight fitting cuts at the heavy joint, then braze the complicated joint all at once. If I have to add another tube at a busy junction, just add flux and let the existing material at the joint wick onto the new tube. |

| |  |

| | #35 |

| Rock Stacker Join Date: Feb 2007 Location: Aussie Crawlin Sin City

Posts: 93

|

I read this thread last night and this morning I went out and got the filler rod and flux both yourself j and pink recomended...............OMG how very very easy is this stuff to use. before the harris 45t and flux I had only used flux coated fillers for brazing never on tubers mind you just general fab / furniture work just want to say thanks for the heads up on these products Peter |

| |  |

| | #36 | |

| Rock Stacker Join Date: Mar 2008 Location: ITALY

Posts: 59

| Quote:

and... I'm still wondering which gas is better using! Is MAPP the only way to go, or would butane/propane + oxygen, or butane/propane alone be good enough? | |

| |  |

| | #37 | |

| Quarry Creeper  Join Date: Sep 2007 Location: Middle of the USA

Posts: 321

| Quote:

| |

| |  |

| | #38 | |

| Rock Stacker Join Date: Mar 2008 Location: ITALY

Posts: 59

| Quote:

in the mean time a friend of mine had a oxy-acetylene kit that he wasn't using. tomorrow i'm trying something with that | |

| |  |

| | #39 |

| Quarry Creeper  Join Date: Sep 2007 Location: Middle of the USA

Posts: 321

|

Be careful with heating small tubing with a larger torch. You could end up melting the tubing or disfiguring the tube.  |

| |  |

| | #40 | |

| Rock Stacker Join Date: Mar 2008 Location: ITALY

Posts: 59

| Quote:

Today I've tried brazing a couple of iron rods I had and they stuck together quite well the only problem I've had so far is to get the perfectly right flame playing with the 2 valves on the torch, but I guess I'm gonna learn by trial and error and... with the kind help of this forum :P | |

| |  |

|

| |