| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

|

I bought a nice spiral flute tap for about $15 at Palm Abrasives here in town. I've used it with my cordless drill for 2 years and couldn't imagine building something without it. Just drill a #40 hole and zip right through with the tap. One of the best purchases I've ever made.

|

| |  |

| Sponsored Links | |

| | #22 |

| Rock Crawler  Join Date: Feb 2007 Location: Peoria, Arizona

Posts: 919

|

Swarf is my new favorite word.

|

| |  |

| | #23 |

| Pebble Pounder Join Date: Jun 2006 Location: Grand Blanc/Traverse City

Posts: 167

|

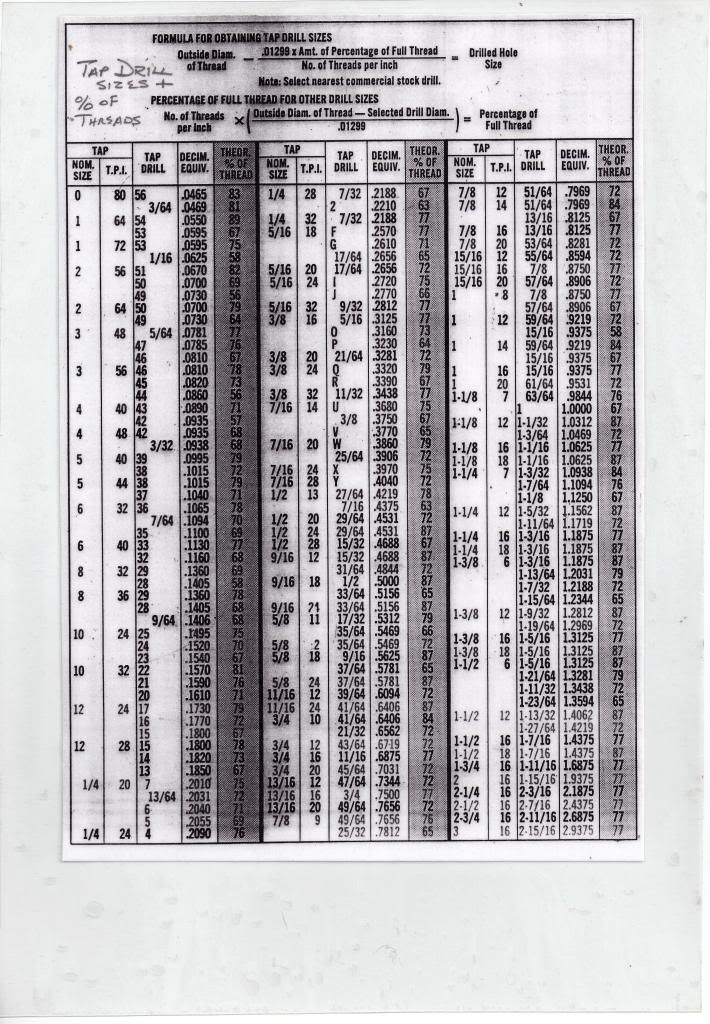

Ok I will post this up I hope that you can read it ok  This is Handy if you cant read it you can go see it in my photbucket and probly donwload it... not sure how photobook works. If not let me know and I will email it to you  http://i782.photobucket.com/albums/y...DrillSheet.jpg |

| |  |

| | #24 | |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

| Quote:

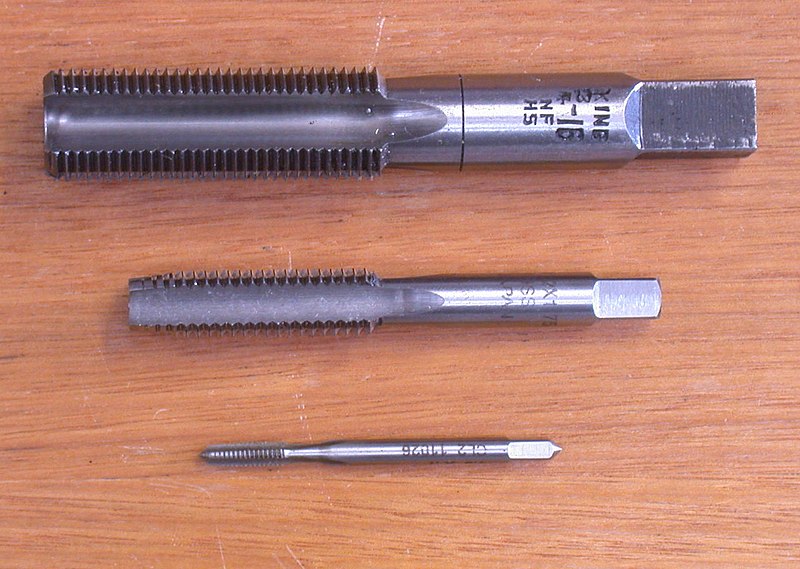

They cut beautiful and are perfect for aluminum but they can break very easy. They do not have the torsional strength of a straight two flute tap. Also FYI, the standard for spiral taps are flat bottoming. This means they do not have a leading taper to help start the tap in the pilot. They're greatest purpose is for tapping blind holes and direct the chips up and out of the hole. If you order a spiral tap, ask for a plug tap to get the subtle taper that helps ease the tap in. Here's a pic of three taps, straight flute. Flatt bottom, plug and taper. (respectively from top to bottom)  | |

| |  |

| | #25 |

| Quarry Creeper Join Date: Feb 2005 Location: Atlanta

Posts: 326

|

Does Snap On make good taps?

Last edited by Bmr4life; 02-25-2010 at 04:49 PM. |

| |  |

| | #26 |

| I wanna be Dave Join Date: Aug 2008 Location: Austin, TX, USA

Posts: 4,273

|

Lately I've been drilling and tapping my own links out of aluminum, thanks in part to Doug's drill bushing. I'm using a tapered M3 tap by hand. I follow what I understand to be proper tapping procedures: Turn the handle and as soon as it starts to resist with significant force, back off a turn or two, and proceed, repeating as necessary. But even using cutting fluid it gums up badly before I've tapped far enough. I can't imagine how y'all do this with a hand drill. Do you just go very slowly? Do you set the torque very low? I can't see how I wouldn't break a tap without taking it very easy. I would love to make more of my own links, but I've gotta say....this is a much bigger pain in the butt than I'd imagined it would be. Any thoughts on what I may be doing wrong or techniques I should be following that I may not be aware of? |

| |  |

| | #27 | |

| RCC Addict Join Date: Oct 2007 Location: Kennewick, Washington

Posts: 1,382

| Quote:

| |

| |  |

| | #28 |

| I wanna be Dave Join Date: Aug 2008 Location: Austin, TX, USA

Posts: 4,273

|

It's 6061...

|

| |  |

| | #29 |

| RCC Addict Join Date: Oct 2007 Location: Kennewick, Washington

Posts: 1,382

| |

| |  |

| | #30 | ||

| TEAM MODERATOR  Join Date: May 2004 Location: Tennessee

Posts: 10,855

| Quote:

Quote:

When I do build things at home and need to tap something in a pinch,a few things that might help.... Dougs drill bushings are awesome,they help allot. Chip build up in the hole is hard on a little tap. I like to use spiral flute taps cause they pull most of the chips out of the hole as they cut. That relieves allot of stress off the tap. Get some good tap magic or tapping oil,dip the tap before you start. I've even used WD-40 at times. Depending on the application,sometimes you can drill the hole a few thou bigger than what it calls for. In a high stress application or something that will be taken apart often,you want to shoot for getting a full thread. When I do tap with a drill,I do go slow,but leave the torque setting on high. Cheap chinese taps probably wouldn't take much abuse long. The 3 and 4 mm taps I have are probably some of the better taps out there,I know they were proud of them. | ||

| |  |

| | #31 |

| Rock Crawler  Join Date: Jun 2009 Location: SF

Posts: 604

| Ha!! Snap on taps are a bit of a joke! They are pretty good because they are made by Hansen. The joke part is the price, I bought a snap on set years ago and my shop mate has the same set from Hansen, exactly the same down to the plastic case they are in, I paid 3 times more than him! The only good thing is if you have a really good Snap On guy, he'll warranty broken and dull ones for you! |

| |  |

| | #32 | |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Quote:

One thing I always do with blind holes, is use a needle attachment on my air hose to get in and blow the chips out. Wear your glasses though since it does make the crap fly. Nothing worse then spending time to properly tap a hole, and have it ruined by the screw because it's full of chips at the bottom. This is especially true for holes that will see repeated action like beadlocks. | |

| |  |

| | #33 |

| Pebble Pounder Join Date: Dec 2008 Location: Tomball, Tx

Posts: 168

| just in case it wasn't clear, and don't forget to if you have ever had to get some small piece of steel out of your eye you will remember this. if you are lucky it can be removed with a magnet. here is how it is done http://www.liveleak.com/view?c=1&i=6d4_1218830417 dont forget the glasses! |

| |  |

|

| |