| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 | |

| Quarry Creeper Join Date: Feb 2005 Location: fresno

Posts: 213

| Quote:

| |

| |  |

| Sponsored Links | |

| | #22 | |

| Rock Crawler Join Date: Feb 2006 Location: Easthampton

Posts: 747

| Quote:

| |

| |  |

| | #23 |

| Quarry Creeper Join Date: Feb 2005 Location: fresno

Posts: 213

|

do you have your gun strait or is it got a roll in it? dose your in case-(i cant rember the corect name right now) need to be replaced? i got down with alum to from a mig a it was preety

|

| |  |

| | #24 |

| Pebble Pounder Join Date: Dec 2005 Location: Fenton

Posts: 132

|

I im gona go with 3/16's Steel tube. and MIG it together.. I was looking at HULK's Moon buggy project and his welds turned out preatty good..

|

| |  |

| | #25 | |

| I wanna be Dave Join Date: Jun 2004 Location: San Jose

Posts: 5,207

| Quote:

As for a tubing vs. rod tubing is stronger because you are bending four plains vs two. But brake line is annealed to make it easy to bend. I use 1/4" DOM or 1/4" 4130 for my tube projects and I always stand on the chassis and bounce a little to test the strength. If my 200 lbs *** won't even flex the frame I know it's good to go. I wouldn't try that with a brakeline chassis. | |

| |  |

| | #26 |

| Quarry Creeper Join Date: Jan 2006 Location: Ukiah, CA. (nor cal)

Posts: 275

|

your welder "can" do aluminum.....all it will take is $1,200 for a spool gun adn controler to hook up to your welder...LOL... DOM or chromo for a RC now that's taking it serious..... |

| |  |

| | #27 | |

| Pebble Pounder Join Date: Dec 2005 Location: Fenton

Posts: 132

| Quote:

| |

| |  |

| | #28 | |

| Quarry Creeper Join Date: Feb 2005 Location: fresno

Posts: 213

| Quote:

| |

| |  |

| | #29 |

| Rock Crawler Join Date: Feb 2006 Location: glastonbury

Posts: 992

|

i used 5/16 304 stainless .020 wall. my 11 pound rig fell off a 9 foot tall rock and landed one inch worth of the front end of the frame and it dented it a little bit. i tig welded it myself (not an easy task but doable) the frame did dent in the fall but it gives it character. the only problem with the 5/16ths is that its too big to look scale but i wasnt that concerned. also one thing to keep in mind is that some people on this site build much smaller crawlers than others. a 2.2 (from what ive seen) is usually half the size of a maxx crawler or similar. so if you havent picked the tube yet consider the stainless, its better than painting  |

| |  |

| | #30 |

| Quarry Creeper Join Date: Feb 2005 Location: fresno

Posts: 213

|

how do you hold the tig when you did that tubing? i hold it like a pen and free hand it how bout you?

|

| |  |

| | #31 |

| Rock Crawler Join Date: Feb 2006 Location: glastonbury

Posts: 992

|

i always free hand, i just wrap the cable one wrap around my arm so i dont have to fight the weight of it and hold it similar to a pen.

|

| |  |

| | #32 |

| Quarry Creeper Join Date: Feb 2005 Location: fresno

Posts: 213

|

good thats the easyst way. i was doing that today, but w/o gloves |

| |  |

| | #33 |

| Rock Crawler Join Date: Feb 2006 Location: glastonbury

Posts: 992

|

haha i dont use gloves either just pay attention to how hot everything gets lol

|

| |  |

| | #34 |

| Quarry Creeper Join Date: Jun 2005 Location: quarryville

Posts: 299

|

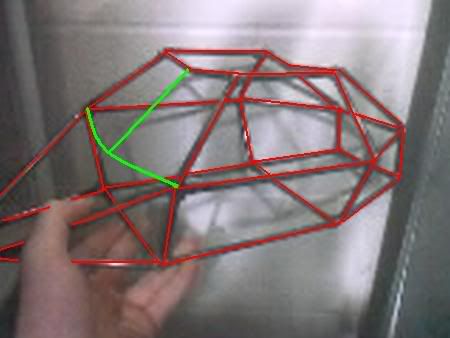

im building mine right now just like that  |

| |  |

|

| |