| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Aug 2005 Location: VARCOR

Posts: 1,826

|

There are plenty of threads out there in reference to the multiple of fabbing machines available to the home DIY RC'r, but not really a thread on the actual parts/pieces created. I am mainly interested in custom aluminum parts produced with mills and lathes, but whatever custom RC parts you have created will work also. If you don't mind going into some detail, please list the tooling used to create the part, and any tips that could be useful to someone looking to create a similar product.* I am looking into maybe going and buying my own el-cheapo mill this week, but I need a little inspiration before I fork out the dough! Show off your skills!!!!!  * I don't mean to start this as a way for others to "copy" other's ideas, I just want to hear of the basic tips that could be used in the construction. |

| |  |

| Sponsored Links | |

| | #2 |

| 2006 2.2 National Champ  Join Date: Dec 2004 Location: Big Bear Lake

Posts: 8,328

|

There's some good stuff here. Show off time... |

| |  |

| | #3 |

| RCC Addict Join Date: Aug 2005 Location: VARCOR

Posts: 1,826

|

Great link Bender, Thanks!!  Exactly what I wanted to see! Exactly what I wanted to see!Others, don't be scared to continue to post.................... |

| |  |

| | #4 |

| Pebble Pounder Join Date: Apr 2006 Location: Barcelona

Posts: 195

|

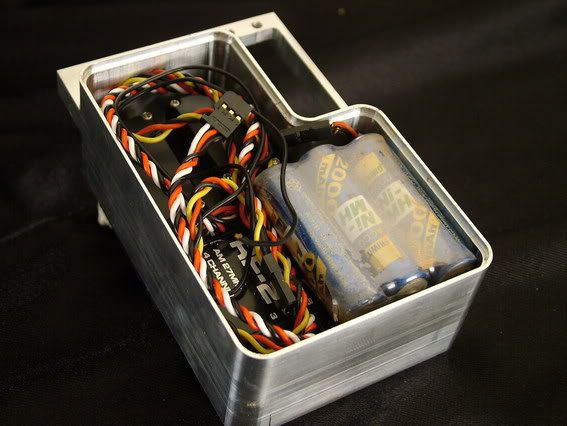

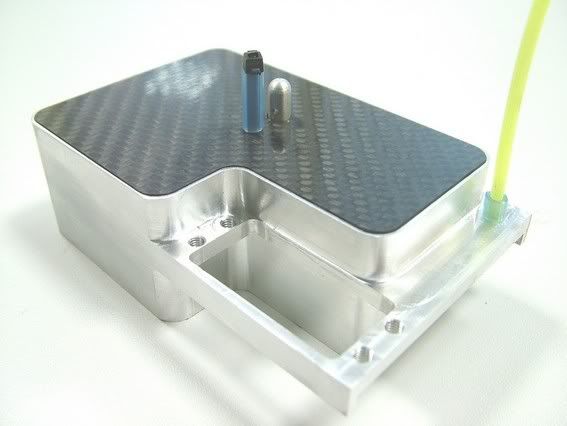

not all crawling projects but custom made  Tribal Clod chassis  Crazy buggy skies  RDlogics Wolverine mod.    XTM mammoth parts.  And my most famous custom part, HPI Savage batery an receiver box, I designed it a long time ago when I bought my first Savage, but untill today more than 300 units have been sold, normally I don't make parts for other people but as the Savage box sucks and I have a hobby shop that orders 50 pieces each time, why not to make some extra cash for the hobby?     All parts made with NC milling machines in my work shop. Last edited by kazi; 01-08-2007 at 03:34 PM. |

| |  |

| | #5 |

| Newbie Join Date: May 2005 Location: Holland

Posts: 21

|

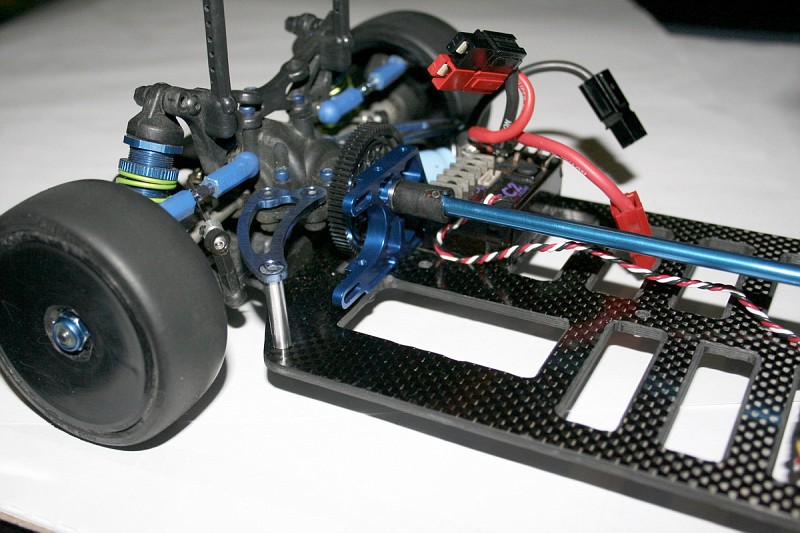

Head, carb adapters, exhaust system, N2O injection.   Rims, front axle, fuel tank, exhaust system, driveline (clutch, dogbone etc)  |

| |  |

| | #6 |

| Rock Stacker Join Date: Jan 2006 Location: Clackamas

Posts: 56

| |

| |  |

| | #7 | |

| Rock Crawler Join Date: Jan 2007 Location: Long Island NY

Posts: 505

| Quote:

| |

| |  |

| | #8 | |

| RCC Addict Join Date: Dec 2004 Location: Central NY

Posts: 1,980

| Quote:

| |

| |  |

| | #9 | |

| Quarry Creeper Join Date: Mar 2006 Location: Australia

Posts: 495

| Quote:

yep.... what he said!! | |

| |  |

| | #10 |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

|

Mine aren't as nice as Roydelburgs, but then I build all my parts with a bandsaw, drill press, and a mill from 1971. This is the first part I ever made with the mill. It's the bracket for my front dig servo and rear link mounts.   Steering servo, lipo battery, and front link mount, all in one.  Even made the frame side-plates. Mostly with the band saw, Oh yeah, and don't forget the drill press.  |

| |  |

| | #11 | |

| Rock Crawler Join Date: Dec 2005 Location: Marietta

Posts: 917

| Quote:

| |

| |  |

| | #12 |

| Quarry Creeper Join Date: Jan 2007 Location: wilkes-barre

Posts: 313

|

War Pig, what thickness aluminum is that?

|

| |  |

| | #13 | |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

| Quote:

| |

| |  |

| | #14 | |

| Built, not bought  Join Date: Oct 2004 Location: Gresham

Posts: 4,504

| Quote:

See you at work. | |

| |  |

| | #15 |

| RCC Addict Join Date: Jun 2006 Location: Maryland

Posts: 1,255

|

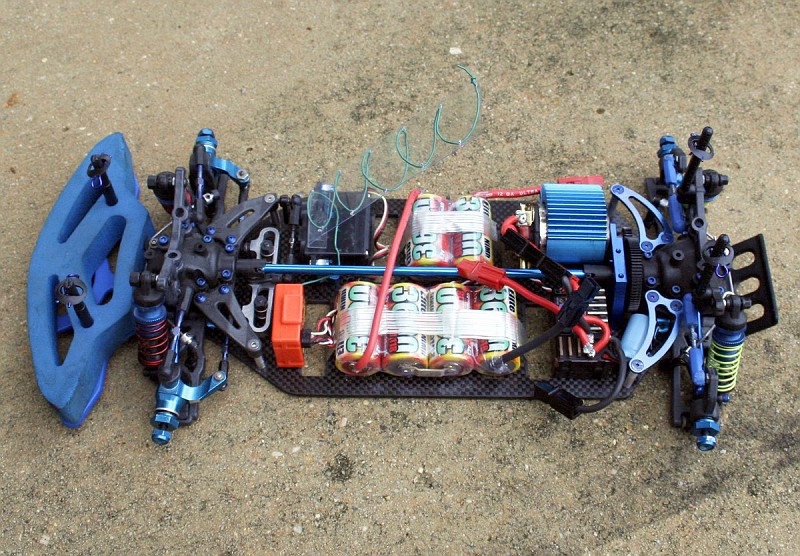

here is my basher super "beefcake"  |

| |  |

| | #16 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

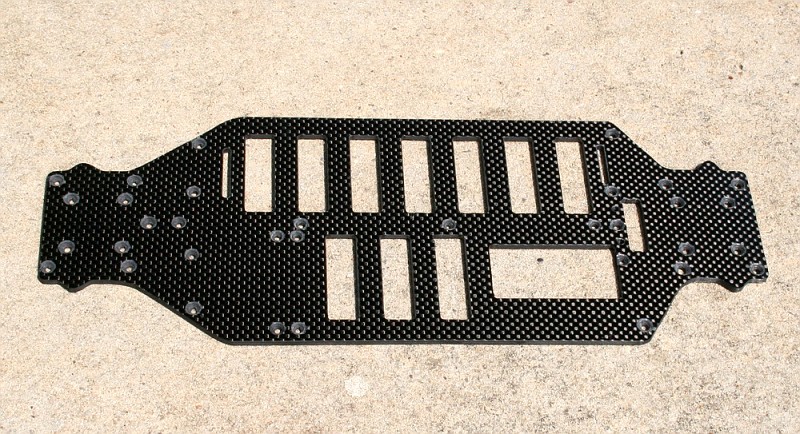

Man, I love this stuff! This chassis for a TC3 took me a couple hours on a vertical mill...    Always wear a respirator when milling carbon fiber!! |

| |  |

| | #17 |

| Quarry Creeper Join Date: Jan 2007 Location: Osaka, Japan

Posts: 425

|

I think machining is a pretty kind word for my hacking and dremeling, but here are some pics of my projects, first a shortened Wild Dagger chassis (still a work in progress):  and some Clod axle stiffener/shock mounts I made:   and decorated with magic marker:  all made out of plastic cutting board, using a Dremel and a craft saw. Not pretty, not the best, but cheap as......The chassis for the Dagger and the mounts for the Clod cost a grand total of -val (not doing it well, but doing it cheap!) |

| |  |

| | #18 | |

| Pebble Pounder Join Date: Jan 2007 Location: So.Cal

Posts: 138

| Quote:

JOe | |

| |  |

| | #19 |

| Rock Stacker Join Date: Feb 2007 Location: Kingsport

Posts: 55

|

Dang, sweet!!!!  |

| |  |

|

| |