| | #1 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

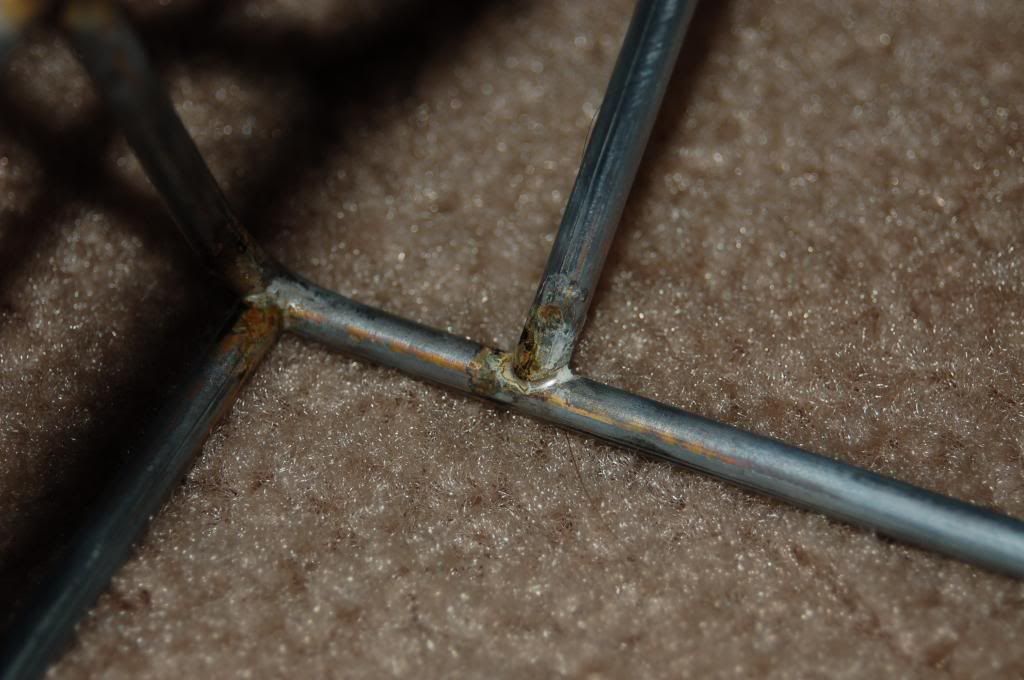

So I debated whether to start a build thread or not for this rig seeing as I feel like I barely have time to work on it let alone update you all on the progress.   Rear axle is underdriven and front axle has XR10 narrow axle steering mod. Home made delrin beef tubes and aluminum hop-ups all around. Quick mock up.    This is my first time brazing so I need a little advice. I'm using Harris Safety Silv 56%. Some of the joints look pretty good but some leave a little to be desired. These are the worst joints I've done so far. What can I do to make them better? Do I just not use enough Silver Solder? Sometimes I feel like the more I use the more just runs inside the tube instead of joining the two together.   Anyway. Let me know what you all think. Good or bad. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Aug 2011 Location: round pond (aka clarksville TN)

Posts: 1,454

|

tighter fitment of the tubes where they meet will make for better and nicer looking joints all around  |

| |  |

| | #3 |

| I wanna be Dave Join Date: Jun 2007 Location: Arlington wa

Posts: 2,100

|

when that happens to joints im brazing together I pull the heat back some so the solder barely heats up and melts.. seems to fill the voids, and the better the fitment with a fishmouth would also help  |

| |  |

| | #4 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

I am doing a fishmouth on the tube, that one was just a little crooked so the bottom of the fishmouth wasn't parallel with the other tube. Sounds like I need to be a little more precise though on tube fitment. Thanks for the advice guys. Blakeski, that's a good idea trying to keep the solder thick. I'll give that a try on the tubes that didn't fit as well as I'd like. I've gotten some more done since so look forward for more pictures.

|

| |  |

| | #5 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

You are using flux, right? Try to apply the flux only to where you want the solder to be. That way you solder will stay confined to a specific area. Looks good. Practice makes perfect.  |

| |  |

| | #6 |

| Rock Crawler  Join Date: Oct 2012 Location: Garden Grove

Posts: 546

|

Looks like too much heat and not enough solder. Some of the other joints look good though. |

| |  |

| | #7 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

So I've made some progress on this and just haven't posted yet because I'd rather build than post.  But seeing as it's 107* outside But seeing as it's 107* outside  I wanted to get rid of the stock plastic shock hoops so I fabbed up some of my own.   I also slotted the frame so my hood would sit down where is supposed to and this is the overall effect you get.    I still need to finish the back end, make fenders, and a front bumper. Then I'll start triangulating stuff. After that's all done then I'll need to figure out how to put on the little nuts to attach body panels. So you guys that have done this before, how do you hold the little nuts in place while you braze? I have the little helping hands for soldering but the heat killed the springs inside the alligator clips the first time so now they don't hold anything. And how do you make sure that no solder gets in the threads? I know the solder only goes where the flux is so don't put it in the threads but the flux bubbles and runs and I'm afraid it will get in the threads. Any suggestions? |

| |  |

| | #8 |

| Newbie Join Date: Mar 2008 Location: Puyallup

Posts: 36

|

Some really narrow tube fenders would look good on the front following the contour of the hood. Your doing a great job for your first time brazing.

|

| |  |

| | #9 |

| RCC Addict Join Date: Oct 2006 Location: crawlifornia

Posts: 1,612

|

this is looking good

|

| |  |

| | #10 |

| SuperShafty.com Join Date: Jan 2008 Location: Visalia CA

Posts: 2,902

|

yeah it looks like you might be getting it a tad too hot, and the joints need to be tighter.

|

| |  |

| | #11 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

Any advice for brazing nuts? How do I hold them there and how do I make sure no solder gets in the threads?

|

| |  |

| | #12 | |

| RCC Addict Join Date: Oct 2006 Location: crawlifornia

Posts: 1,612

| Quote:

what I usually do is pre tin the tube where the nut will go, just putting a little dab of SS and quickly pull the heat away before it flows too flat, then I go back and reheat the spot and just as it melts again I dip the nut into the SS because it heats up faster than the tubing, then pull away before it flows into the threads, but it usually doesn't. Oh and I hold the nut with needle nose pliers. Doe that help? Any other ideas? Last edited by rockhugger; 07-13-2013 at 12:13 PM. | |

| |  |

| | #13 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

Dude that is genius! Sounds like that method will take a little practice but I think I may be able to manage that. I'll go ahead and give it a try. Thank you so much for your help.

|

| |  |

| | #14 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

Updates! I finally got it a roller. It's sitting a little taller than I'd like for ride height but I'm thinking that the weight of electronics, battery, body, tranny, etc. will pull it down. If not I'll run a little bit of droop to get it where I want it. I also need to pull the front axle back just a touch to keep it centered in the well and keep the tires from getting in the grill at full lock. I may have to pull the front shock hoops off and re-braze them farther back if I have to move the axle very far.   Back end view.  At this point guys I really need some help. I had an idea for a front bumper but its not going to work out with the insane amount of steering the XR10 mod gives me. I need something with decent coverage but narrow enough to keep out of the tires at full lock. Any ideas? The only thing I'm really set on is a grill hoop. Something like this. http://www.rme4x4.com/gallery/d/5293...5+_Medium_.JPG Here's a picture of the front end to give you an idea of the space I have to work with.  Any opinions are greatly appreciated as I'm really up in the air on what I want in the front bumper. |

| |  |

| | #15 |

| Rock Stacker Join Date: Jul 2013 Location: dixon

Posts: 78

|

looks good so far, i've seen the bumper kinda wrap around the grill and headlights on these jeep bodys and it looks pretty sweet

|

| |  |

| | #16 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

So I took rockhugger's advice putting nuts on. It seemed to work pretty well the first day. Then the next day I tried it the same way and they just wouldn't stay put!  I also threw in some windshield and roof bracing. You know when I started out I thought my braze joints looked fine. Now as I've taken advice from others I find that my joints have improved and the old ones just look nasty. Thanks for the help guys.    I was browsing through other people's build threads trying to find inspiration for a front bumper. Thanks to MG200 and his creativity I think I found what I was looking for. Obviously I'll tweak it to fit a jeep hood. What do you guys think? MG200Designs - KOH full chassis |

| |  |

| | #17 |

| Rock Crawler Join Date: May 2012 Location: Minneapolis

Posts: 858

|

For brazing on nuts I've usually used a sacrificial bolt that I use the hold the nut and the braze it into place. Then I turn the bolt out. The reason I say sacrificial is because the bolt gets discolor end and even warps a bit sometimes. Another way I've seen that I want to try is to use some wire to tie the nut in place. Braze and cut away the wire. A quick hit with a dremel to remove any pieces of the wire that were stuck in the braze. Haven't tried this yet but will be on my next project. |

| |  |

| | #18 |

| RCC Addict Join Date: Aug 2010 Location: wherever paypal sais.

Posts: 1,740

|

Good lookin build you got going. Cage design is pretty awesome. I like it.  But I like most jeeps.. lol |

| |  |

| | #19 |

| Quarry Creeper Join Date: Sep 2011 Location: hemet

Posts: 296

|

Have you been removing the coating on the tubing? It looks like you are using coated brake line and when I use that I have to wire wheel or sand off the anti corrosion coating before I can make a decent connection.

|

| |  |

| | #20 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

| This is coated brake line but it's not the polyvinyl fluoride coating that looks like enamel paint. It's a super terne coat which looks more like just galvanized steel. Just chuck the stuff up in your hand drill and hold scotch brite to it. Takes it off real quick.

|

| |  |

|

KOH Jeep - Similar Threads

KOH Jeep - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| 1.9 KOH Jeep | Just Zach | Axial SCX-10 | 159 | 04-30-2013 11:42 AM |

| Jeep Wrangler YJ KOH | the-gamer | 1.9 Scale Rigs | 17 | 04-13-2013 12:23 PM |

| KOH Jeep CJ5 | minnesotamudder | 1.9 Scale Rigs | 7 | 04-16-2012 06:25 PM |

| KOH Jeep | xigtc | 1.9 Scale Rigs | 11 | 05-10-2011 06:13 PM |

| |