| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Jan 2015 Location: Burlington, ON, Canada

Posts: 87

|

I am building my Wraith kit, and noticed the diff turns nice and freely as long as I pull on the pinion when I'm turning it. If I push the pinion towards the ring gear, it has a bit of play/slop, and it seems to contact the ring gear more and binds badly when turned. So as long as there is tension on the pinion shaft it works great, it's just when I put pressure on the pinion shaft and try and turn it is doesn't turn as well. Is this normal, is it anything to be concerned about, and can it be fixed?

|

| |  |

| Sponsored Links | |

| | #2 |

| Pebble Pounder Join Date: May 2013 Location: kinzers

Posts: 180

|

I had same problem I just got tiny washers/shims and put them on pinion shaft before install driveshaft that put the pull on the pinion been good ever since

|

| |  |

| | #3 | |

| Rock Stacker Join Date: Jan 2015 Location: Burlington, ON, Canada

Posts: 87

| Quote:

| |

| |  |

| | #4 |

| Quarry Creeper Join Date: Jan 2011 Location: 808 via Reno, Nv.

Posts: 242

| You should have some play in between the spur gear and pinion gear. The way I set mine up is when using 48p gears I use a piece of paper torn in a small strip and placed it between both gears and apply a little pressure on the motor towards the spur gear and tighten it down, then pull the strip out. If it doesn't tear your golden. 32p gears I fold the paper in half and apply the same method. Hope this helps. |

| |  |

| | #5 | |

| Rock Stacker Join Date: Jan 2015 Location: Burlington, ON, Canada

Posts: 87

| Quote:

| |

| |  |

| | #6 |

| Rock Crawler Join Date: Feb 2011 Location: Spur, TX

Posts: 541

|

While browsing SuperShafty.com a coupled days ago I learned they are selling thrust bearings now to help with this issue. AR60 THRUST WASHER MOD - Super Shafty |

| |  |

| | #7 |

| RCC Addict Join Date: Aug 2013 Location: Missoula

Posts: 1,346

|

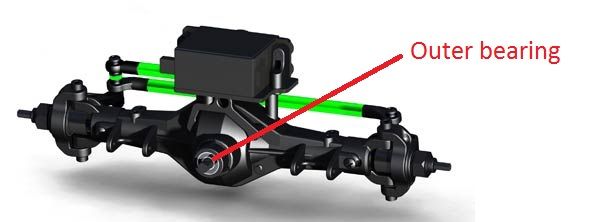

Use 5mm shims inside the housing between the pinion gear and inner bearing to set the backlash of the gears. Just a little play, not tight. Then use 5mm shims between the outer bearing and the driveshaft, so you can just get the pin in. You want zero in and out movement of the pinion gear. |

| |  |

| | #8 | |

| I wanna be Dave Join Date: Jul 2013 Location: Minneapolis

Posts: 5,202

| Quote:

| |

| |  |

| | #9 | |

| RCC Addict Join Date: Aug 2013 Location: Missoula

Posts: 1,346

| Quote:

These look much nicer, but that extra .5mm may be too much. I think I'll give them a shot http://www.amazon.com/Bearing-5x11x4.../dp/B002BBQ604  | |

| |  |

| | #10 |

| ~THE SCALE SHOP~ Join Date: Apr 2006 Location: KILLEEN TX

Posts: 10,056

|

I run 5mm thick bearings on the outer pinion bearing for this very reason. especially on VP housings. on stock housings mine didnt seem as bad. but i may still run the 5mm thick bearings or shims i had the same issue, with inward pressure on pinion the axle/gears would bind/lock up. with pulling on pinion the axle would spin freely. these are what i run. alot easier than fooling with thrust bearings. http://www.ebay.com/itm/251092804442...%3AMEBIDX%3AIT http://www.ebay.com/itm/160504687993...%3AMEBIDX%3AIT Last edited by STANG KILLA SS; 02-04-2015 at 04:56 PM. |

| |  |

| | #11 | |

| Rock Crawler Join Date: Dec 2013 Location: Tuxedo NY

Posts: 582

| Quote:

| |

| |  |

| | #12 | ||||

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| Quote:

Quote:

Quote:

Quote:

| ||||

| |  |

| | #13 |

| Rock Crawler Join Date: Dec 2013 Location: Tuxedo NY

Posts: 582

|

i had the super shaft thrust bearings for a week, until the front diff started slipping gears and making a clicking noise. i went back to regular bearings...

|

| |  |

| | #14 | |

| Quarry Creeper Join Date: Jan 2011 Location: 808 via Reno, Nv.

Posts: 242

| Quote:

| |

| |  |

| | #15 |

| Newbie Join Date: Jan 2016 Location: Mount Perry

Posts: 8

|

I have a question, but first Id like to tell you how helpful this site is, wow, outstanding. It looks like STANG KILLA SS's ceramic bearings are what im going with UNLESS someone has gave the 'DLUX AR60 Wraith Bearing Mod' a go, and has good news. Anyone try that yet?

|

| |  |

| | #16 | |

| I wanna be Dave  Join Date: Feb 2013 Location: NW Indiana

Posts: 3,196

| Quote:

| |

| |  |

| | #17 |

| I wanna be Dave Join Date: Aug 2004 Location: central VT

Posts: 2,300

|

It seems that Axial has never cared about giving us the needed shims to properly set ring/pinion mesh. I put together 1:1 ring/pinions, so I'm a bit OCD about ring/pinion setup. If you just stack up shims outside the housing odds are good your pulling the pinion too far away from the ring gear and actually reducing gear contact and worsening mesh slightly. You'll need 10x12x.1 to sit under the carrier bearings. If you pull off the bearing caps you'll likely find that the carrier/ring gear can shuck back and forth in the housing quite a bit. This significantly changes gear mesh. Adding shims behind the carrier bearings allows you to precisely adjust where the ring gear sits side/side in the housing. You'll need 5x7x.1 shims for the pinion shaft. Oftentimes this requires so many shims I'll start with .2m thick shims. I also add solid spacers between the pinion bearings so that once everything is shimmed and the driveshaft is tightened there is literally no slop in the pinion shaft. Once your pinion depth is set, and you solid spacer is installed you put whatever thickness of shims on the outside so the driveshaft buts up snug against them once tightened. The solid spacer I use is from the original generation HPI Blitz rear hub spacer. It was originally used to hold the rear wheel bearings at the proper spacing, allowing you to tighten the wheel nuts without crushing the bearings together. It serves a similar purpose in this application. The solid spacer also helps force the bearings to share loads. I've found that the stock sintered gears typically benefits from .1-.3mm worth of shims behind the pinion gear inside the housing to bring it closer to axle centerline. Do this before shimming the ring gear/carrier. It seems that for every .1mm you move the pinion towards centerline, you can ditch about .3-.4mm worth of shims behind the ring gear side of the carrier and transfer them to the other side and keep similar gear backlash. This relationship is important to understand, othewise you spend WAY more time swapping shims around to find the sweet spot. The deeper the stock pinions sit to centerline the more of the pinion gear actually contacts the ring gear. More gear contact=stronger. The helically cut HD gears do not respond similarly, they have a prefered pinion depth to result in the best mesh that can only be found with trial and error. Seems some don't want any shims under the pinion gear, others want .1 or .2, but so far never more. IMO the stock sintered gears are stronger than most think, but only if they are properly shimmed before being run. They wear quickly if the mesh isn't perfect. |

| |  |

| | #18 |

| RCC Addict Join Date: Jun 2006 Location: Durham, NC, USA

Posts: 1,164

|

^ so, for the helical cut Axial HD gears, running no shims is fine? If not, where and how many shims should I use?

|

| |  |

| | #19 | |||

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| Quote:

Quote:

Quote:

Shim or at least check if all gears need shimming...shim as needed. | |||

| |  |

|

Pinion gear and ring gear mesh question - Similar Threads

Pinion gear and ring gear mesh question - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Ring and pinion gear side ??? | Bullitrockcrawl | Axial Wraith | 1 | 09-02-2011 08:24 AM |

| Pinion Gear/Mesh? | 28offroader | Venom Creeper | 9 | 01-26-2011 01:21 AM |

| RS4 pinion and ring gear set-up... | chris_dishmon | HPI Wheely King | 39 | 12-26-2009 05:41 PM |

| bevel gear, ring gear mesh | rocksteadily | Tamiya TLT Crawlers | 5 | 05-09-2009 12:04 AM |

| Spur and pinion gear mesh | desertfox62 | Axial AX-10 Scorpion | 15 | 01-17-2009 04:35 PM |

| |