| | #1301 |

| I wanna be Dave Join Date: May 2006 Location: HONDURAS...ROCK HEAVEN

Posts: 5,076

|

cool deal, I can't wait for mine , I am already looking for arms and springs to start building my stuff  |

| |  |

| Sponsored Links | |

| | #1302 |

| I wanna be Dave Join Date: Sep 2009 Location: Nor Cal

Posts: 2,213

|

It's a lot of fun. I'm on my third armature right now. I'm hooked!

|

| |  |

| | #1303 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

| |

| |  |

| | #1304 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

I was goofing around this weekend and rebuilt (as best as possible anyway) a fried 15t hpi firebolt sealed can motor. Rewound it and cut the comm on the lathe. Not much to do for the brushes other than scuff 'em up and reuse them. Anywho, I decided to try the "chuck it up in a drill and see the kv" thing. I did the math and it came out to approximately 3500kv. That didn't sound right at all, so I tried another, much better quality 27t motor and it came out to 4375kv. The drill spins @ 1400 rpm, the 27t motor put out .32v. 1400 (rpms) x 3.125 (1/.32) = 4375 rpm's per volt, right? |

| |  |

| | #1305 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Yer formula is correct... Keep in mind, many 27t motors are pure RPM machines....they would cut the crap out of the arm until there was nothing left. It was not uncommon to see racing stock motors make more RPM than a 19t race motor, which was required by the rules to use a full stack armature. Later EddieO |

| |  |

| | #1306 | |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

| Quote:

That 27t is one I wound on a Reedy 15t arm and it looked fairly normal, but I know what you're talking about. I've taken some 27t's apart and there wasn't much meat there. | |

| |  |

| | #1307 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

|

Epic Binary stock comes to mind with high rpm stock motors. Checked the kv on one a while ago and it was 4880. Thing has pretty much no steel in the arm at all. |

| |  |

| | #1308 |

| RCC Addict Join Date: Nov 2006 Location: Lowell, Arkansas

Posts: 1,307

|

.....and "stock" race motors have 24 degrees timing and laydown brushes. Both affect Kv. Try checking the stock motor in both directions and see the difference.

|

| |  |

| | #1309 | |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| Quote:

| |

| |  |

| | #1310 | |

| Rock Crawler Join Date: Apr 2009 Location: Pa

Posts: 563

| Quote:

Keep an eye on the ways for knicks. (I see there is already one on yours) When I first got mine there was a knick on the one way which caused the lathe to turn a taper. I stoned the knick out and it took the taper out. Why isn't this thread a sticky yet. | |

| |  |

| | #1311 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

| |

| |  |

| | #1312 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

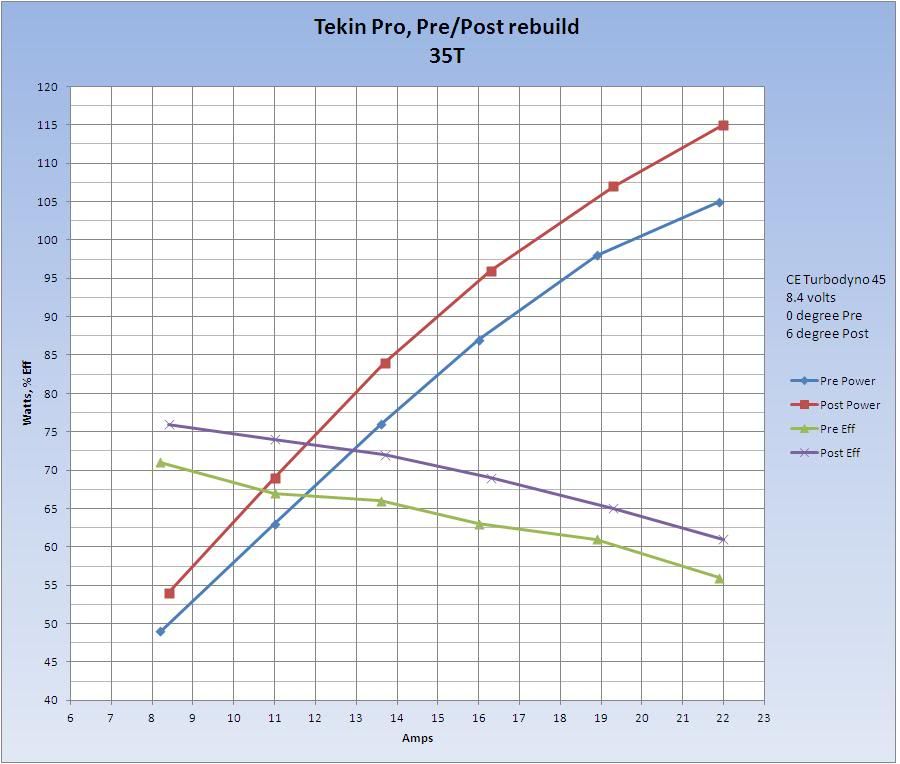

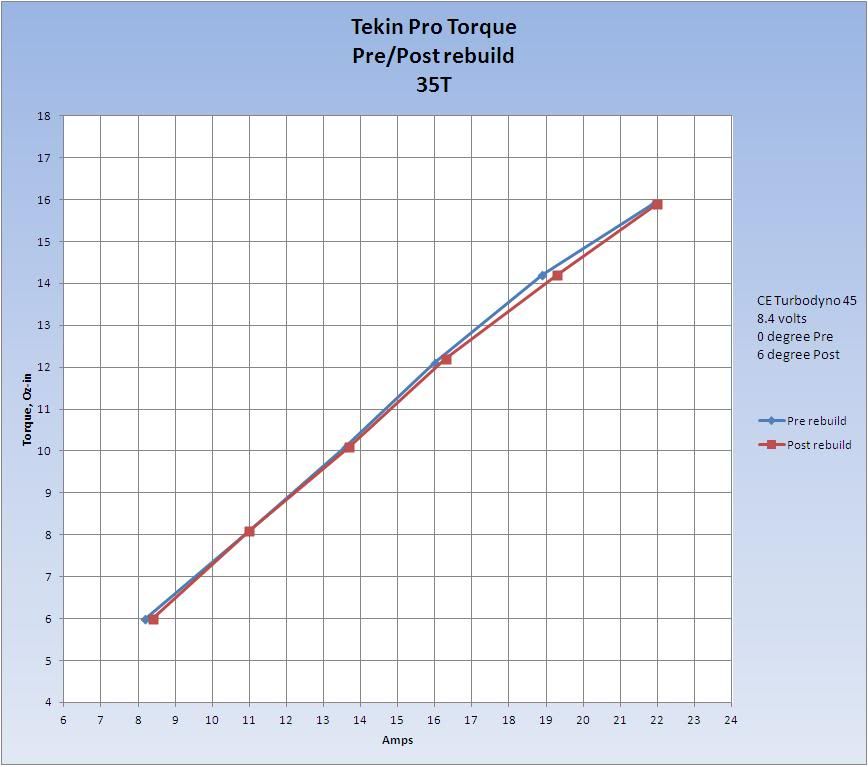

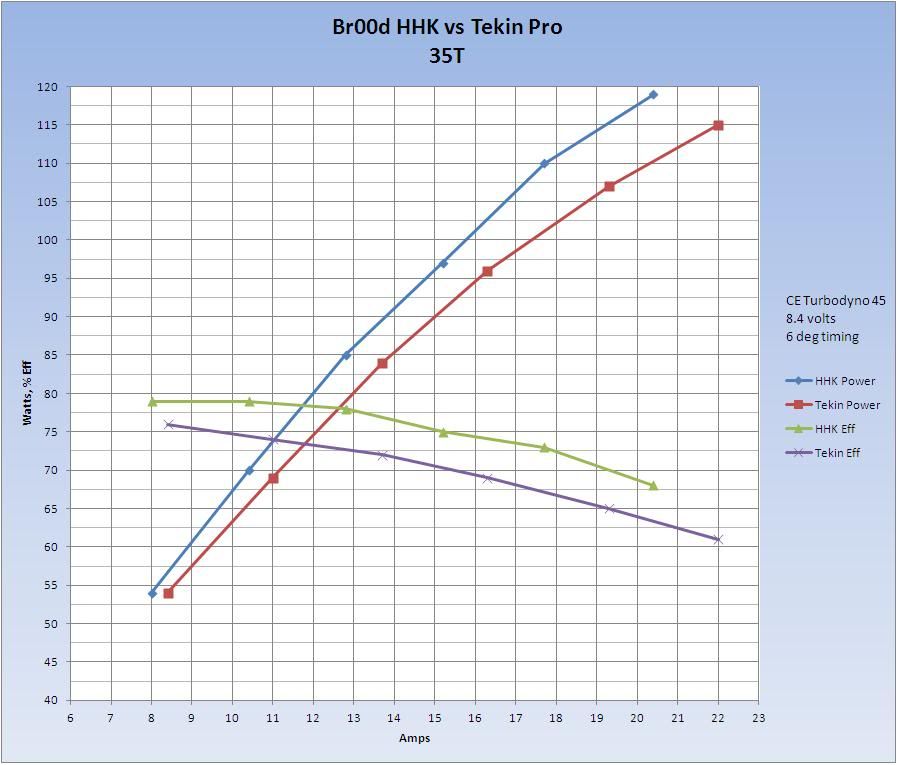

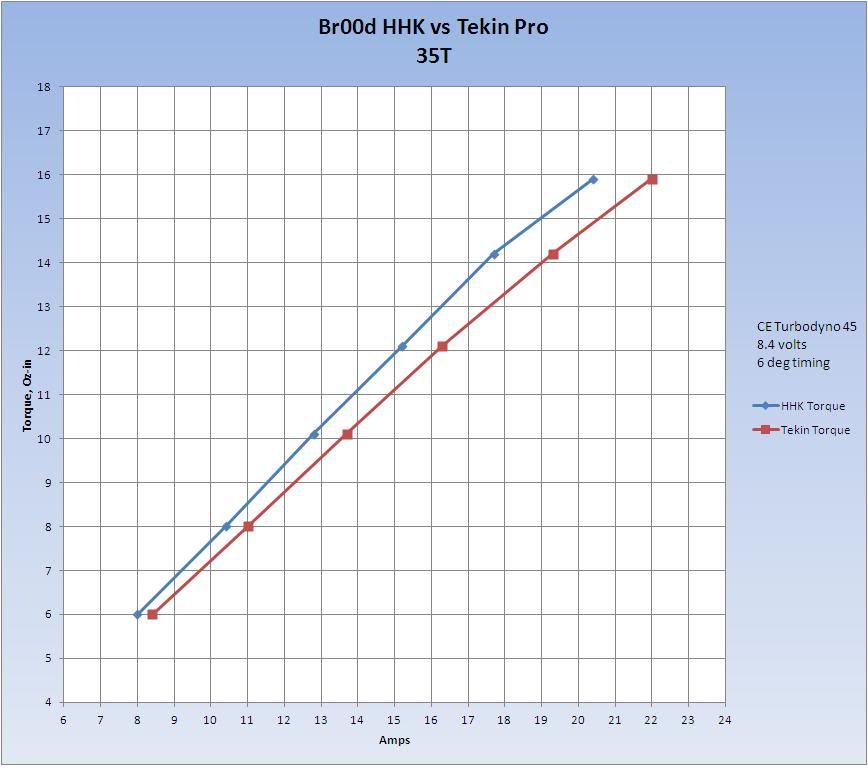

I was playing around with some graphs to show a better visual. Here is a comparison of the Tekin Pro pre rebuild vs post rebuild/tune. Note that it's not apples to apples as the pre rebuild is the motor at 0 degrees timing in excellent condition, likely what it would be as provided from Tekin. The post is at a crawler friendly 6 degrees timing advance. I think it shows how an off the shelf motor could be better with some tuning and small timing advance.   Here is a comparison of the post rebuild/tune Tekin vs. the HHK in the P-94 can   Last edited by Cordwood; 01-13-2012 at 03:13 PM. |

| |  |

| | #1313 | |

| I wanna be Dave Join Date: Sep 2009 Location: Nor Cal

Posts: 2,213

|

Hey dkf A nick on what? Can you please explain for me? The comms I have turned have exact OD at both ends. BTW, that was my first com cut. I'm getting better with each one. Thanks for the input  Quote:

| |

| |  |

| | #1314 | |

| Rock Crawler Join Date: Apr 2009 Location: Pa

Posts: 563

| Quote:

When I got my lathe as I said it was cutting a taper. My knicked way was on the longitudinal feed though which caused the taper. I was running over the raised metal from the knick which caused the taper. I stoned down the raised portion and the taper went away. The aluminum on these lathes is heat treated but it is still fairly soft. I was just giving you a heads up so you can avoid issues. | |

| |  |

| | #1315 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

| |

| |  |

| | #1316 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

Nice graphs yo!

|

| |  |

| | #1317 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| |

| |  |

| | #1318 | |

| I wanna be Dave Join Date: Sep 2009 Location: Nor Cal

Posts: 2,213

|

Thanks for the heads up dkf  Quote:

| |

| |  |

| | #1319 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

I was rebuilding my motors (Brood 35T HHKs) to get ready for ACC and I had one of my best cuts yet....so I thought I'd post a pic: (I know, the camera is shitty and has a hard time focusing on the comm)  |

| |  |

| | #1320 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/electronics/223989-cutting-motor-commutator-motor-tweaks.html | ||||

| Posted By | For | Type | Date | |

| Hiilimoottorin kunnostaminen | This thread | Refback | 10-04-2011 03:19 PM | |

| |