| | #1201 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Your unit should of came with one. I used to have a pic somewhere of a flywheel that spun off a dyno in a hotel room.....it went through the wall and was stuck in the NEXT wall in the adjacent room. Unseated brushes make a decent difference in power. 1. No, they are in fiddlestick units. Some where in this thread I have posted the chart of FSU for the trinity springs. 2. Depending on the firmware the max voltage is like 9 volts I think....might be wrong, as I have never tried to increase it past 8.4. It's possible newer firmwares allowed higher voltages. 3. There is no answer to this, as all the brushes are different lengths to a degree. I tend to say no more than 20% of the original length gone is time for a replacement. 4. Uh, there is more brushes than I can count. 4455,4499,4503,4500, 767,768,769, 766, F-Brush, Putnam (Green, Blue, Red), Sprint(various versions), Enduro (various versions),XXX in laydown just off the top of my head. Standup, 4383, 4380, 729, Enduro, Sprint, F-Brush, XXX, CS Brush ($30 a pair!), and more.....thats not counting all the unique brushes like Checkpoint, V2, P94, and Trinity's hexagon and Oval..... As for pros and cons of each, well......that would take days to explain! I can tell ya that brush choice is MUCH less critical in a crawler motor than in a race car. Not only would we mess with different compounds, we would often mess with different cuts, holes, etc on them. I've dabbled a little in cuts on crawler motors....very hard to see the difference cause you can't measure laptimes, just dyno results. A good 27t stocker will be in the high 120s, while a great one will break into the 130s at 7.2 volts. I will point ya to a thread on hobbytalk when I get home with all the robi info. Later EddieO |

| |  |

| Sponsored Links | |

| | #1202 | ||||||||||||||||||||||||||||||

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| So my next mission is to perfect brush break in and hood alignment. I'm way off power wise on what a good 27T stock motor should be if high 120's at 7.2 is normal, because I'm barely making 120 at 7.5 volts. Will bearings make a big power difference over bushings? If so, and assuming bearing size is standard, I could pop some out of another motor to put in this one for testing purposes. If found this on the fiddlestick units:

Man, that's too many brushes for me to figure out. I'll order "brushes" and run whatever you send. | ||||||||||||||||||||||||||||||

| |  |

| | #1203 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

Has anyone used the Integy brush master? The one I have is used, and didn't come with a manual. I have a silver can motor in it and ran it off a 3 or 4 cell nimh. Seemed I had to push really hard for a long time to get any good serrations in the brush.

|

| |  |

| | #1204 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

A quick look didn't turn up a manual though. | |

| |  |

| | #1205 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

|

Cordwood: I have the same serrator, you have to push the brush like hell to get serrations unless you follow that link that Charlie-III posted. I just use a small drop of 3-in-1 oil and it makes for a lot less effort. I would ignore the oz. rating compared to colours of the springs as well. I know Big Jim used to say that they vary so much batch to batch that you just go by F.S. units to keep consistency. |

| |  |

| | #1206 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

I had the same problem with whatever brand this thing is in my picture, but when I do the serrating with the brush located as shown in the picture, it works pretty much perfectly. In other words, I don't use the grooves to hold the brush, I freehand it and use my fingers to hold it and give it a little back and forth movement and the serrations are good and done in a only a few seconds. I have to flip the brush over 180 to hit the other half, maybe doing half a time is the reason it works for me? A good pile of brush material to the left, that was from four brushes. I couldn't get a damn flake of shit when I did it in the groove.

|

| |  |

| | #1207 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| I have dozens of springs and they do all Fiddle Stick way differently than each other. THe same color is usually within a single digit, like between 6 and 7 FSU's or 6.5 and 7.5 FSU's, so they're not too far out, but they're not the same, that's for sure.

|

| |  |

| | #1208 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

Linky.... *Team Brush Serrator (Laydown/Std/Type 94) for R/C or RC - Team Integy | |

| |  |

| | #1209 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| |

| |  |

| | #1210 | |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

| Quote: | |

| |  |

| | #1211 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| |

| |  |

| | #1212 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

By the way, this Integy works a whole lot better with some lube. I didn't have any liquid wrench but a drop of some trinity oil helped a ton.

|

| |  |

| | #1213 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

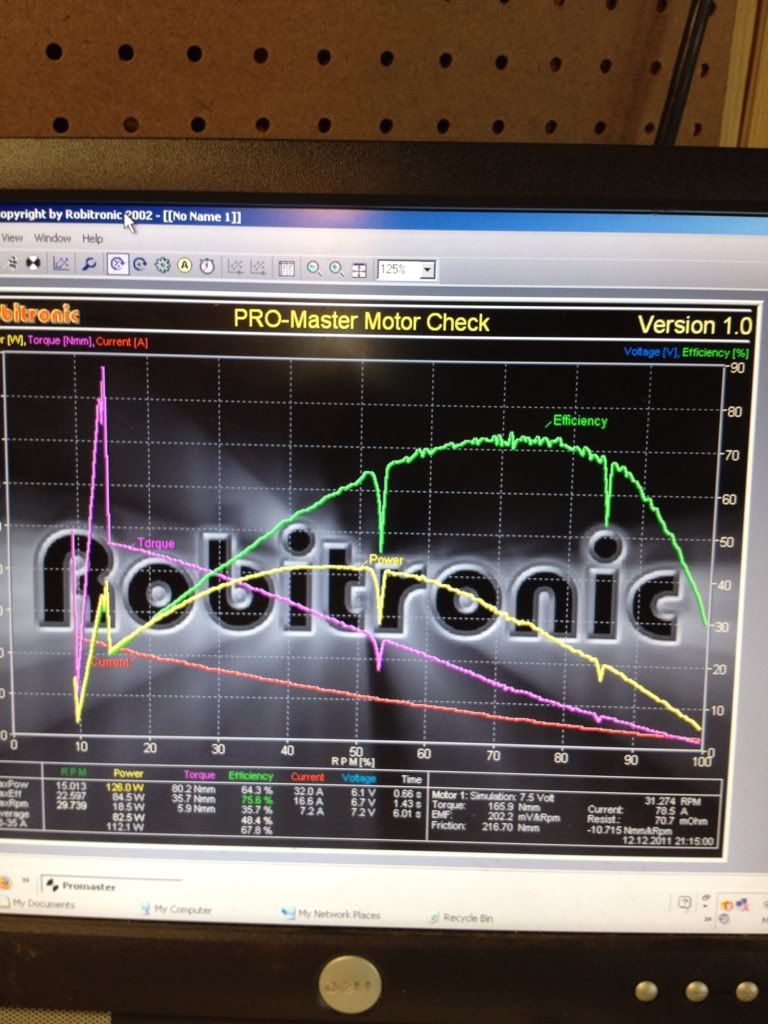

More testing tonight. I spent some time aligning the brushes better. Springs 9.5 positive and 8 negative ---------------rpm------power------torque-----eff------current-----time Max Power---13605----126---------88.6------57.7-----36.8--------.56 Max eff--------19939---105.7------50.6-------70.5-----23.2--------1.06 Average-----------------83.3--------------------45.6 Avg 18-35---------------106.8------------------66.6 That 105 at 19k rpm watts is suspect to me I installed some used bearings after that and saw a pull slightly better than above with 129 peak watts. It went down hill after that. Couldn't get anything consistent. I think the brush hoods moved because suddenly the brushes were off center again. After messing with it for an hour, I ended up with about the same as above. Only notable change was an average power between 18-35 amps was up to 110-112 and efficiency is up a few percent. I was having problems getting smooth pulls. I kept getting getting a big spike in the curve at startup and a sparking sound as well as random dips later in the pull. I thought the startup spike could be weak brushes but i tweaked the springs up to a 10 FU range and no difference. Here's a graph that shows both.  I guess I'm done with this motor. On to something else. Crappy integy maybe. Here's a 10 turn P-94 for your viewing pleasure. Check my ghetto flywheel cover. I'm gonna paint it pink and put a Br00d sticker on it. http://i583.photobucket.com/albums/s...s/0e9f90b0.mp4 |

| |  |

| | #1214 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

| Cheers for the Tip EeePee....I'll give that a burl tonight and see how it goes.  But the serrating head on yours looks a lot finer than the one i have... But the serrating head on yours looks a lot finer than the one i have...To me 1 f.s. unit is still a fairly big deviation for springs that are meant to be 'the same'. Corwood: 8+f.s sounds high if you're still working on the stock motor from before. Eddie might chime in with his experience, but the highest i ever ran on the stock motor was 7.5 on +ve and that was in 6cell rubber touring. You should hear a 6 or 7t on a dyno....It's one way to annoy the neighbours put it that way.  Last edited by WIDELOAD; 12-13-2011 at 12:20 AM. |

| |  |

| | #1215 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

Others may do something different, but we all have our needs from a motor. Way back when, part of the "need" was making runtime. | |

| |  |

| | #1216 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Towards the end of the brushed racing days, we were running super stiff springs, sometimes blacks. Pretty much every stock motor for touring car that left the shop was sporting tweaked purples. For crawlers, I typically use the purple as a starting point. It seems to be a good mix of power and drag brake. Lately though, I've seen a lot of people using the stiffer silver or even the blacks.....the 5 segment motors require a stiff spring, and it helps on the 4 magnet stuff too. Back in the day, the wrong spring or brush would kill you......literally DUMPING in 2wd Stock offroad.......sucked. Now its a joke, even with a brushed motor you can run for 15 minutes with a 4000 mah lipo pack. Later EddieO |

| |  |

| | #1217 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

One last round of messing with this 27 turn motor... I moved the brush solder joints and spring posts so the positive and negative springs are the same type instead of opposite. I also soldered on some copper tabs on the dyno cables to solder to motors instead of the alligator clips. Made a couple pulls and results were similar to above. Since the soldering iron was hot, I installed a P-94 hood conversion kit that was laying around just for something to do. It came with some single shunt copper/bronze looking brushes and some more silver looking double shunt brushes. Started with the coppers and after brush alignment, break in and some spring tweaking it was similar results to above, maybe a little less. Then I installed the silver brushes with purplemsprings, broke them in and made my last pulls on this motor. -------------- rpm-------power----------torque---------eff--------current-------time Max power---13666----126.7----------88.9----------58.9-------36------------.56 Max eff-------21393----91.3------------40.8---------73.5--------18.6----------1.25 Avg----------------------82-----------------------------47.5 Avg (18-35)-------------110---------------------------68 55 turn Integy up next. Is any of this interesting to anyone or am I just cluttering up a good thread with useless info? Eric |

| |  |

| | #1218 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| |

| |  |

| | #1219 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

|

Thanks for that info on the springs Eddie, good bit of insight...I know my old Brood CO27 stock has purples both sides, but i haven't checked the tension numbers cause the comm is past minimum diameter to actually run it in anything. I've never had a dyno to chase that last watt, I always just found a base set-up that worked and tweaked the springs, brushes etc. to suit lap times and feel. Corwood: If i remember right the silver looking brushes will be 4383s. Very aggressive on the comm, but made decent power. The more copper looking ones will be 4380s i think. |

| |  |

| | #1220 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

| Roger that Yup, you nailed that. |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/electronics/223989-cutting-motor-commutator-motor-tweaks.html | ||||

| Posted By | For | Type | Date | |

| Hiilimoottorin kunnostaminen | This thread | Refback | 10-04-2011 03:19 PM | |

| |