| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

|

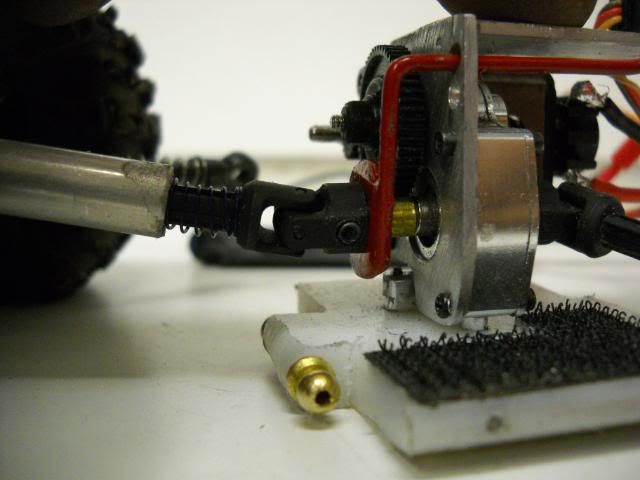

Someone already did the BIG BLOCK but I thought I would see where I could take it. I wanted a DIG and a tuber like a campbell racer. I made a trany plate that the servo can mount to and it also offers space on top for the electronics. That's a PN racing 80t motor. With a custom mount it fits nicely...I just wish I could use a smaller pinion. This one is the small gear from inside the trany. I have yet to try it out so I can't offer any results at this time. I can't wait to see how much better this motor is on a heavy rig with QLO's.   I can also say that the mod works better on the aluminum trany. The tollerances on the plastic housings messed with me for a while. I was also able to get the motor gear mesh tighter on the aluminum housing.  A washer welded to a custom bent wire. Smoothest dig ever at this point!   This is what I am building mine after. I have built one of these for evey size crawler in the past...super, 2.2, and 1.9. It's just something I got-to-do!  Mine won't quite be scale...the QLO's will be like 44's. These are like 37's.  I will be working on the tuber this week. I hope to be successful. |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Oct 2010 Location: Newport, South Wales

Posts: 257

|

I hope you are successful as well because it will be one kick ass looking crawler if it is. I have always liked the look of that type of tube frame, it will be nice to see it on a small scale. The work you did on the trans plate/servo mount looks great, the arm for the dig also looks much better than your previous ones. |

| |  |

| | #3 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

I got a lot done on the rig last night...it's looking good. I will post some frame shots soon. | |

| |  |

| | #4 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Very interesting build keep up the exceptional work.

|

| |  |

| | #5 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

Awesome. what are you going to use for the chassis/cage? The Dig is freggin genius. by a vendor star so you can make me one!!! LOL or post a lot more pics so i can try... |

| |  |

| | #6 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

The other thing is the motor...will it be what I have been looking for? The magnet strenght on this is 100 x stronger than the stock motor. I am hopeful. I wish i could find smaller electronics that didn't cost a ton. It's sooooo tough fitting in an ESC, 3 channel receiver, battery, and a dig system. I think this one will be a 5" to 5 1/2" wheel base. | |

| |  |

| | #7 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Setting a high bar there!!!! Very nice work! Onward and upward! I sure would like to see a pic of the collar/sleeve that connects/disconnects the 'shaft from the output. I doubt I'll dig my rig, but there's always my next Crawler. I just wish the rear could freewheel without power being put to it. |

| |  |

| | #8 | |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

| Quote:

| |

| |  |

| | #9 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

| |

| |  |

| | #10 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

|

Actually the rear axle doesn't stay locked up as you drag it...it often rolls. I actually would rather it lock up. I have thought of ways to add a locking mechanism to the dig arm to lock up the driveline.

|

| |  |

| | #11 |

| Rock Crawler Join Date: Dec 2005 Location: houston

Posts: 650

|

Lookin good DANALLY! I amd working on antother rig and was thinking of using the same motor, so hurry up and let me know how it works! Think it would handle 3s?? |

| |  |

| | #12 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

I think I will have it running in a day or two and post a heads up on the motor findings. I am really worried about the pinion size being so big. I hope the low end is ok. There is no way to add a smaller pinion gear unless I flip the motor to the front of the trany and make spacers to mount the motor to. And with the dig unit you can't add the aluminum 56t spur gear...it contacts the drive line ring. I guess there will be more to come! I am also going to do a step by step on the dig system since a few people want more pic's. Should I post it on a new thread just called "how to build a dig"? I looked at the dig servo and it has no markings and of course I trashed the package. I think its a sub micro 5.4g. I just picked it up at my local hobby shop. They aren't cheap...$25 if I remember right. A normal size steering servo works fine but it's just so big. You would be supprised at how strong this little servo is. I gotta go pick up some more tubing from there so I will find out the make and # soon. | |

| |  |

| | #13 | |

| Rock Crawler Join Date: Dec 2005 Location: houston

Posts: 650

| Quote:

This is the method I was planning to use so I could run a smaller pinion. Might still try it in 3s and see what happens! And thanks for the info on the servo, Ill be watching your build for sure. Good luck! | |

| |  |

| | #14 |

| Rock Crawler Join Date: Nov 2008 Location: Nor*Cal Cameronpark

Posts: 510

|

If you find your low end not up to par stick some neodymium magnets in that can..I love my 70t PN with neos smooth low end & wheel speed the best of both worlds... Great job on the dig  |

| |  |

| | #15 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

Did the magnets do that much good? If so...I think I should do it. Are you running yours on the stock ESC? | |

| |  |

| | #16 |

| Rock Crawler Join Date: Nov 2008 Location: Nor*Cal Cameronpark

Posts: 510

|

The magnets are worth every penny.Way more torque than with the stockers..I run mine on the stock esc 2s lipo 900 mah, the motor & esc don't even get warm after 30 min thats on a heavy rig almost 2lbs |

| |  |

| | #17 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Where did you source that motor Danally?

|

| |  |

| | #18 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Here is the motor http://www.kenonhobby.com/PN-Racing-...n_p_43051.html here is the neo magnets http://www.kenonhobby.com/PN-Racing-...t_p_43237.html And here is a ball bearing case that comes with neo magnets and silver brushes...I am not positive on this one but it looks like it's supposed to fit any 130 motor. http://www.kenonhobby.com/PN-Racing-...t_p_42225.html |

| |  |

| | #19 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

Sweet! I will order them today. Did you change the can on yours to the ball bearing and silver brushes? It's only $13 for the can with magnets, brushes, and bearings. | |

| |  |

| | #20 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Thanks for those links!!! She's definitely a big girl to fit. The shaft is huge! What pinion gear was used? A tranny gear?? Kinda cornfused there. |

| |  |

|

| |