| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| MWRCA'er Join Date: Apr 2004 Location: Machesney Park IL

Posts: 3,995

|

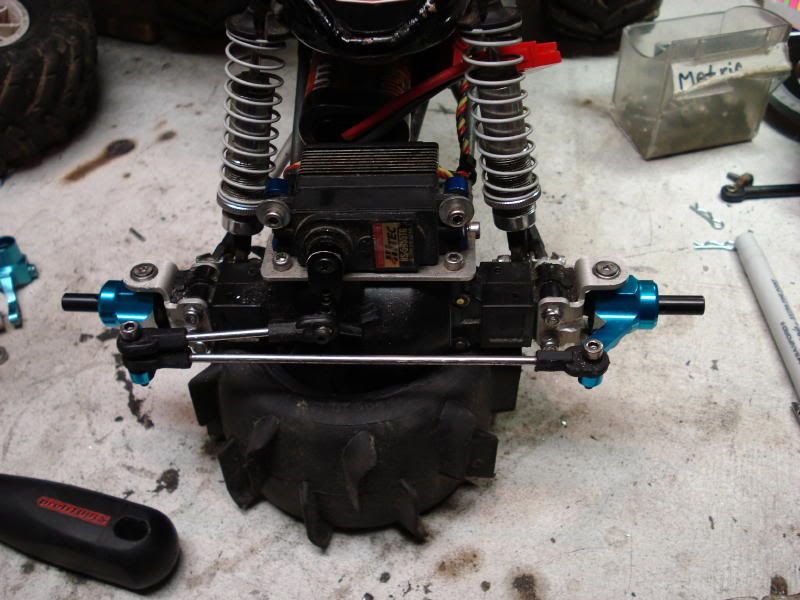

Fat rock hubs are great, but over time they get a lot of slop. It is to be expected, two dissimilar metals rubbing together without lube. We all no what happens when you don't use lube. My screws or pivot pins were even knurled so I had a file like effect going on with every turn. It was getting worse and worse and worse till I thought it was effecting the way the truck was handling off camber sections. Reminded me of how bad my Bruiser knuckles slop around. Anyways, being tired as hell for some reason I woke up today with a solution. Bearing supported steering.   Before  Step 1. Remove the knuckle  Step 2. Put your safety glasses on then find a 7mm drill bit and drill. Size of the drill bit doesn't really matter as long as it is not larger then 5/16. In soft metal like this I would use high speeds and low pressure to avoid ripping through the metal. The idea here is to make the final cut centered clean and easy.  Step 3. No turning back now, find a 5/16 drill bit and drill the holes. Be very careful to keep the drill upright and level.  Step 4. Raid your TLT parts boxes for those bearings that came with the TLT kit that you no longer use. As you can see mine were at the bottom of my parts box rolling in the dirty corner for a long time. Clean them up and use them, if you don't have them I belive the size is 5x8x2.5 width doesn't matter much if you can't find that size.  Step 5. Press the bearings into the holes with needle nose pliers.  Step 6. Hunt for some 3mm flat head screws, or you can use traxxas shoulder screws if you desire more strength at the sacrifice of ground clearance.  Step 7. Bolt it all up and enjoy your zero slop, bind free steering.  Last edited by Mnster; 06-06-2007 at 11:52 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Feb 2007 Location: CoMo...Kickin it with Holmes Hobbies

Posts: 805

|

nice job...great idea...does the axle C still hold up with the smaller wall around the screws...

|

| |  |

| | #3 |

| Oppan Gangnam Style  Join Date: Jun 2005 Location: Shingle Springs

Posts: 5,164

|

Looks good!  I might have to try it. I might have to try it.

|

| |  |

| | #4 | |

| MWRCA'er Join Date: Apr 2004 Location: Machesney Park IL

Posts: 3,995

| Quote:

| |

| |  |

| | #5 |

| I wanna be Dave Join Date: Apr 2004 Location: SoCal

Posts: 5,027

|

Looks great Mnster. We are having the Fat Rock C's priced out in Stainless Steel. This should help out with issues some may have with early wear and slop.

|

| |  |

| | #6 |

| RCC Addict Join Date: Mar 2007 Location: des moines

Posts: 1,104

|  |

| |  |

| | #7 |

| Quarry Creeper Join Date: Jul 2006 Location: Ontario, NY

Posts: 254

|

Nice mod, but is there anything holding the knuckle from moving up and down other than the axle? It'd seem that the whole knuckle assembly now has nothing holding it inside the larger hole as the screws don't exceed the diameter of the bearing. Maybe flanged bearings would be better? |

| |  |

| | #8 |

| I wanna be Dave Join Date: Apr 2004 Location: SoCal

Posts: 5,027

|

I like this idea alot. MNster what is to keep the bearings seated in the C ? Couldn't it eventually become loose and the the bearing slide either up or down out of the knuckle? This could easily be solved by the use of a shoulder bearing. Mabey we should have the next batch opened up and offer the shoulder bearing to go with it? edit: gstealer beat me to it. |

| |  |

| | #9 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

Hmm I have a bag of flanged bearings, I might have to get some axle C's and try this |

| |  |

| | #10 |

| Rock Crawler Join Date: May 2006 Location: Surrey, BC, Canada

Posts: 870

|

Hmmm.. I can see a mod happening to mine REAL soon... My Fat Rocks are sloppier than a hooker after being in a superbowl winners locker room... Nice idea.. I'll hafa see if my LHS has that size of bearing... AWESOME idea...   |

| |  |

| | #11 |

| I wanna be Dave Join Date: Aug 2005 Location: G6'N

Posts: 7,391

|

great write up, will be trying this out shortly.  |

| |  |

| | #12 |

| RCC Addict Join Date: May 2005 Location: I live Here

Posts: 1,218

|

so you only do it ot the top or also to the bottom ? ? ?

|

| |  |

| | #13 | ||

| I wanna be Dave Join Date: Oct 2006 Location: Martinsburg WV

Posts: 2,781

| Quote:

Quote:

Flanged bearings would be the ideal solution. Good thinking Mnster - I can't believe the amount of wear visible in your "before" pic, that's totally unacceptable (at least to me) Nice job overcoming an obvious flaw in the design... | ||

| |  |

| | #14 |

| I wanna be Dave Join Date: May 2006 Location: Arlington, VA

Posts: 3,377

|

yeah, ive thought of doing a smilier mod but using flanged bearings and a shoulder screw.

|

| |  |

| | #15 |

| RCC Addict Join Date: May 2005 Location: I live Here

Posts: 1,218

| |

| |  |

| | #16 |

| MWRCA'er Join Date: Apr 2004 Location: Machesney Park IL

Posts: 3,995

|

The Cvd axles prevent the knuckle for sliding up and down. The holes were so worn before the knuckles standoffs fit in the holes. This is how these things have always been supported. But your right, flanged bearings would probably be a better fit. I did it to top and bottom. |

| |  |

| | #17 |

| Rock Crawler Join Date: Apr 2004 Location: North GA

Posts: 824

|

Fishmaxx did something very similar a few months back, except he used those flanged bearings and some socket cap screws if I remember correctly. |

| |  |

| | #18 |

| I wanna be Dave Join Date: Apr 2005 Location: Vegas

Posts: 7,172

| |

| |  |

| | #19 |

| I wanna be Dave Join Date: Feb 2004 Location: on a Big Rock

Posts: 7,837

| Yep......did it just before the UTRCRC St Georges Comp in March, and Franky was the 1st to see it  I used a DuraTrax Bearing 3x6mm Flanged http://www2.towerhobbies.com/cgi-bin/WTI0001P?&I=LXD100 Last edited by Fishmaxx; 06-07-2007 at 04:39 PM. |

| |  |

| | #20 |

| MWRCA'er Join Date: Apr 2004 Location: Machesney Park IL

Posts: 3,995

|

Well I'm the first one to go public with the idea so there. |

| |  |

|

| |