| | #21 |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

|

Where are you guys buying your junk?? I'm looking to get some LST's on some kind of beadlock. I was thinking the maximizers with the offset. I guess i need some kind of maxx-adapter too? So I was wondering where you guys were buying from, online. I dont think tower hobbies has any of the stuff i need, which sucks, because it would be cool to have it all come in one box. Thanks |

| |  |

| Sponsored Links | |

| | #22 |

| Quarry Creeper Join Date: Mar 2004 Location: Central NY

Posts: 387

|

You can get LST's and beadlocks at www.stormerhobbies.com www.robshobbiesrc.com has beadlocks too. I also have a set of four just like what you want in the ForSale section. Last edited by Mazlem; 05-16-2005 at 01:07 PM. |

| |  |

| | #23 |

| Quarry Creeper Join Date: May 2004 Location: Hartford, Connecticut

Posts: 355

|

Zero, there is already a post about opposing driveshafts on RCCrawler. It was a 2.2 truck with TLT alxes. It worked for him because you can flip one of the the TLT axles to reverse it's rotation so all 4 tires turn the same way with the different shafts. You could do this with x-factor axles or anything else with a standard ring&pinion setup. Sorry to hear that you're ditching the setup, it really can work well. Can't ya do it in 91 days so Digler doesn't send me a flip-off??? Last edited by fullmodtxt; 05-20-2005 at 12:03 AM. |

| |  |

| | #24 | |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

| Quote:

| |

| |  |

| | #25 |

| Newbie Join Date: May 2005 Location: Aussie in Sin City

Posts: 23

|

I used Associated MGT body mounts they fit across the chassis neatly I used just the mount in the rear and added short posts on the front for the hood bulge heres a link http://www.vegascrawlerz.com/index.p...4&key=11&hit=1 |

| |  |

| | #26 |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

|

I need some advice, but first, I have to give credit where it's due...... Bender, I stole your idea for the shocks, and I am a horrible person! :-) I tried to think of other ways, but I liked the way you had tons of travel without leaning the shocks very far. All i had to work with at the time was some 1/8" thick, 3/4" angle aluminum. I'm not sure how it'll hold up since it's so thin, but it seems strong because of the 90 degree bend, compared to flat 1/8" aluminum. I cant find the 1/4" stuff anywhere. Home-cheapo doesnt have much unless you want steel. To mount the shock to the tower, I used spares of the screws that go through the axle to mount the links. There were 2 silver collars in screw bag G that I used for spacers. There are 2 nuts instead of one to keep from overloading the rubber insulator at the top of the shock, and still be able to tighten the screw to the mount properly. I know the mounts will probably bend in a bad roll, (still looking for 1/4" or higher), but besides that, how is everyone else mounting the shocks to the mounts? And since this thread is worthless without pics..... (i still gotta make the mounts look pretty and all that shiz)    Last edited by Zero; 07-13-2005 at 10:11 PM. |

| |  |

| | #27 |

| 2006 2.2 National Champ  Join Date: Dec 2004 Location: Big Bear Lake

Posts: 8,328

|

I mounted mine in a similar way. I tapped the shock tower for a 3mm screw, then I lock it down with a nut on the backside. My shock towers are thicker so I can get away with it. If you're worried about bending them fab a brace that ties the 2 towers together front and rear. Yours will hold up alot better then flat stock. |

| |  |

| | #28 |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

|

I need help, again, but this time I've already shot myself in the foot.... 144 screws later (commando beadlocks), and I overlooked the fact that the moab's foams are too hard! I've read that some people are cutting or swapping the foam out. I was thinking of making holes, sortof like honeycombing the foams, vertically (towards center from tread), and leaving the sidewalls stiffer by not putting holes close to the edge. Does that sound like a bad idea? Second, servo advice for 4ws.... I hear alot about the 1/4 scale servo's and the power, but also the battery drain. I'm thinking of sticking to the standard size, like the 945MG. they'll be running off an SR. I don't need insane-power, but don't want tired servos like the one i already have. any recommendations? Thanks for any advice! |

| |  |

| | #29 | |

| 2006 2.2 National Champ  Join Date: Dec 2004 Location: Big Bear Lake

Posts: 8,328

| Quote:

The Hitec 945mg's are pretty good servos. I'd stay away from the digital version, go with the cheaper analogs. I've had both and the analog's lasted longer. | |

| |  |

| | #30 |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

|

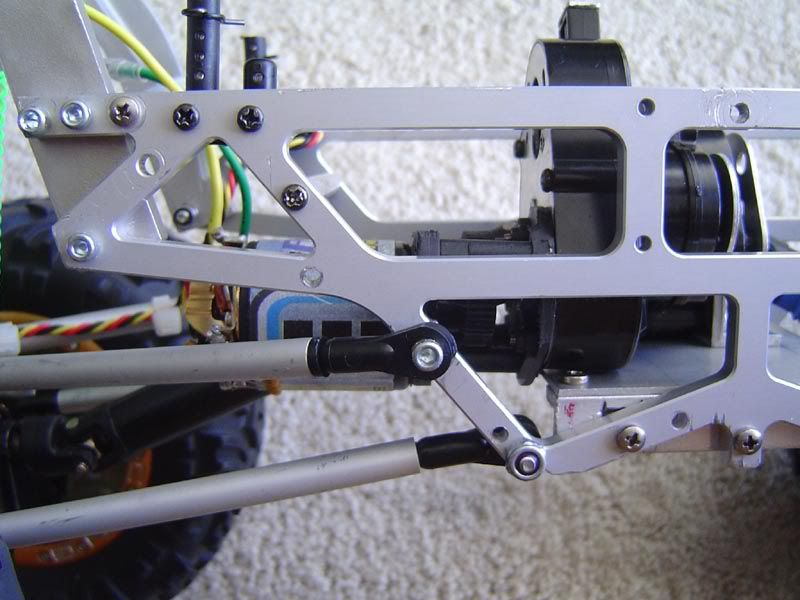

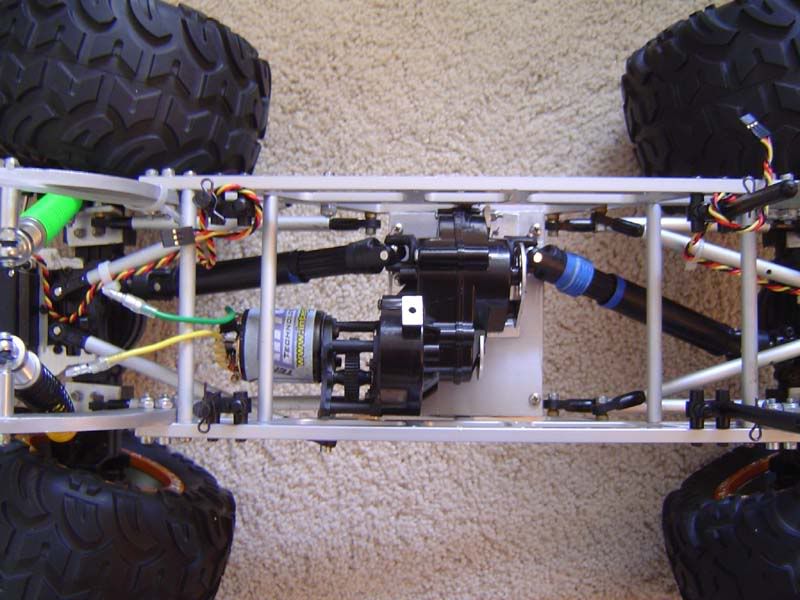

It's been a while since I posted anything, so heres the latest in case anyone is interested.... New shock mounts, and a few other things.... steering is still on the list to be done. I've been beating up the servo i have and waiting for it to die. After that, the 4ws will go on, and not sure whether to go the 945 or 5995 route. The $$ and power consumption make it a tough choice. Thanks for all the advice along the way. I'm really glad that I found this site! Pics....      Last edited by Zero; 08-03-2005 at 04:00 PM. |

| |  |

| | #31 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

The second picture is beautiful. I miss my TXT body now...

|

| |  |

| | #32 |

| RCC Addict Join Date: Nov 2004 Location: Redding, CA

Posts: 1,288

|

Nice shock towers. |

| |  |

| | #33 |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

|

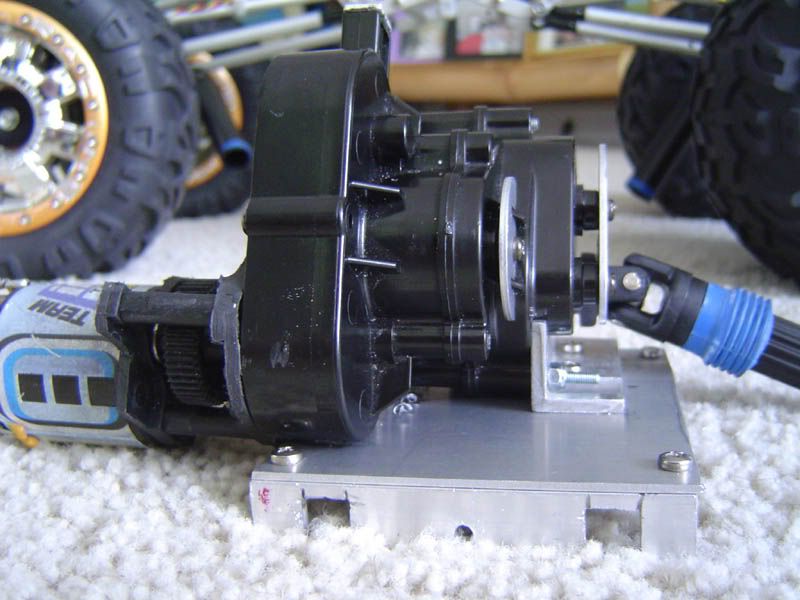

Been a while since I've posted any updates... been working on clocking the tranny. I made a pallet style engine mount, so I could clock the tranny any different way by making small mounts to it. Added the lathe a while ago and some better steering. (Still have the crappy tierod. I get lazy with the easy stuff.)       Theres a skidplate thats not in place on the last pic. I might even make something to protect the motor since it ended up so low! |

| |  |

| | #34 |

| Newbie Join Date: Jul 2005 Location: Australia

Posts: 48

|

Hey Zero, I'm sorta in the same situation you were in a while back, being a newbie to all of this. I just bought a set of Revo shafts and I was wondering how you lengthened your wheelbase to accomodate your shafts, I've been looking at the first set of pics and the rods that join your axles to your frame look stock, so what did you do? |

| |  |

| | #35 | |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

| Quote:

Those revo shafts will work great for you, once you get em to fit. | |

| |  |

| | #36 |

| Newbie Join Date: Jul 2005 Location: Australia

Posts: 48

|

Thanks Zero, I'll have to start thinking about cutting my frame soon, did you have many drama's?

|

| |  |

| | #37 |

| Rock Crawler Join Date: Aug 2005 Location: Asia

Posts: 510

|

this is a very cool build thread ... and im learning a lot as you progress. im am very new to shafty types crawler mt's, and have some questions if you dont mind ... 1] why is the shock towers done that way ... seems like front and rear have different shock mounting angles? also the rear seems higher. 2] why are there 2 different shock springs? 3] have you tested the new rotated tranny, does it work like you envisioned it? im still at stage one of my build, still waiting for some cash to get revo shafts. once i get that then this will pave way to how my fabricated chassis will be designed and implemented. thanks to everyone that has shared so far! |

| |  |

| | #38 | |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

| Quote:

If you do this, the only things you may run into are, you have to move the engine up higher, which means the top engine mounts will run into the canti spring mounts, and also, you'll need a way to secure the bottom of the tranny. At the time, I used 2 of the crossmember tubes on either side of the bottom of the tranny to keep it from moving (forwards and backwards). For the canti spring mounts, i took them out, cut a big notch in them for the engine mounts to go up into, and then i re-drilled a new hole in the canti spring mount and frame for a new bolt to go through to support the canti spring mount better. If you're still stock, then you have to do something about the mounting deck for the electronics, b/c the motors will be pretty high. When i first did it, i went to home depot and grabbed a few of those metal tube things and used them as like a body lift for the electronics tray. I think I also cut some out of the battery tray to get part of the tranny to clear it. Sorry if that sounded complicated, just wanted to give you as much info as i can before you decide to start cutting. btw, you can also cut the revo's to fit if you arent ready to cut the truck up yet. | |

| |  |

| | #39 | |

| Newbie Join Date: May 2005 Location: P-land

Posts: 48

| Quote:

2. I'm playing around with 3 different springs and different shock oil weights at the moment. The pass/rear shock is much stiffer (another Bender-inspired idea) to fight the torque twist. The trinity springs make a world of difference in that corner. The green spings on the pass/front and driver/rear are softer. I tried these out because the effects of torque make it harder for that wheel to compress when trying to climb something. For example, going forward, the torque makes the truck lean toward the pass side. If the front drivers side tire is climbing, the torque helps lift it sortof. So it flexes nicely. But when the pass/side front tire tries to climb, it doesnt compress as easily, and instead, the whole front end tries to come up, leaving the drivers side in the air. So with the softer spring there, it allows that tire to compress, and leave the drivers side tire down. 3. Still testing the tranny. Electronics arent in yet, only thrown in for a quick trial. Seems like it will work well. I like the new center of gravity with the engine low, but I'm still trying to figure out a better place for the battery, then I have to wire it all back up. It fits perfectly but I'm still worried about the effects of torque with the output on the drivers side. Sorry to make you read all that! Once I get on something..... Last edited by Zero; 09-16-2005 at 11:38 AM. | |

| |  |

| | #40 | |

| Rock Crawler Join Date: Aug 2005 Location: Asia

Posts: 510

| Quote:

| |

| |  |

|

| |