| | #41 |

| Newbie Join Date: Dec 2009 Location: Layton, UT

Posts: 7

| |

| |  |

| Sponsored Links | |

| | #42 |

| Pebble Pounder Join Date: Jul 2007 Location: Oveido, Florida

Posts: 181

|

well i got a good tip for anyone who wants more flex. get some ax10 shocks pull the springs out and mount them up.u will get like 3 inchs more flex then what u had with the stocks and ur ride hight will still b the same. it works well for me. thought that i would jet throw it out there

|

| |  |

| | #43 |

| Quarry Creeper Join Date: Nov 2008 Location: N. California

Posts: 424

|

Good info in here, keep it coming.  |

| |  |

| | #44 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

|

anyone trim/round the foam on a flat iron tire?? im not talking about star cutting them im talking like "rounding" the foam, cutting off the corner where the centre tread meets the sidewall, instead of a square shape making a wider "U" shape. was talking to a friend today and he did this to his 2.2 hammers and it made them more squishy.. im looking to buy some 2.2 mud slingers soon so i was thinking about pulling the 1.9 flat irons apart and trying this.. and was thinking of cutting the tires a little bit too as once i get 2.2's the 1.9's will be strictly for winter and snow plowing and a set of chains will live on these tires. |

| |  |

| | #45 |

| Rock Stacker Join Date: Sep 2010 Location: Calahoo, Alberta

Posts: 91

|

I've always rounded all of my tire foams, even the flat irons. Guess I just do it without thinking about it as part of building the tire, left over from my gofast days.

|

| |  |

| | #46 |

| Rock Stacker Join Date: Jan 2006 Location: Mason, OH

Posts: 84

|

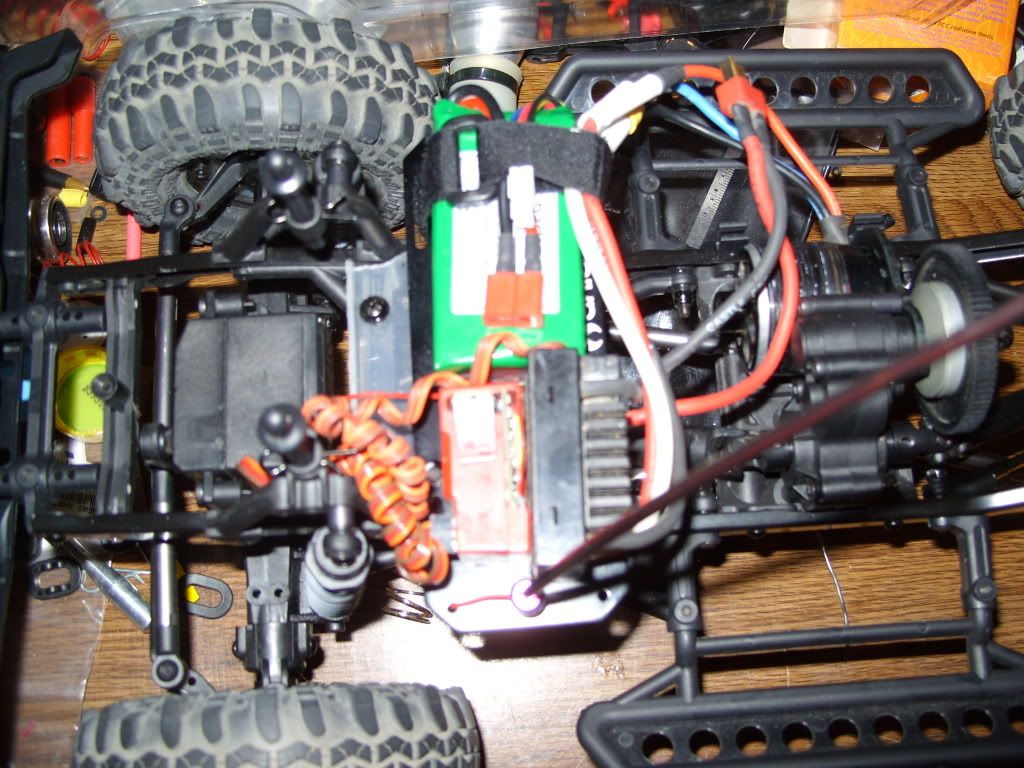

Stock:  Using mostly stock parts and a couple chunks of scrap plastic from the box a servo came in (Sorry for the crappy picture quality). Basically reused the standoffs from the battery tray that hold it above the radio box/front axle, bolted through the battery tray and down into the brackets that snap into the frame for the radio box. Spent $0 on this mod aside from buying a 1300mah battery so the rx/ESC could be relocated to the battery tray.  |

| |  |

| | #47 |

| Pebble Pounder Join Date: Jul 2007 Location: Oveido, Florida

Posts: 181

|

cuttin tires is always a good idea. im runin the flat iron foams in my rc4wd boggers that have all the small lugs cut out and it works well for me on rocks mud sand u name it....

|

| |  |

| | #48 |

| Rock Stacker Join Date: Jul 2004 Location: hell

Posts: 55

|

this is an awesome thread for nOObs like me. thanx guys

|

| |  |

| | #49 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

| thinking about giving this a go today, i got all day hahaha. what did it do to the tire and how do the tires perform afterwards??

|

| |  |

| | #50 | |

| Shelf queen  Join Date: Aug 2008 Location: Internet

Posts: 5,857

| Quote:

You should fab a delrin block to bolt to the two holes top side of each axle end, and then tap a hole down it's length to attache the shock bootm. | |

| |  |

| | #51 |

| Rock Stacker Join Date: Mar 2008 Location: South Australia

Posts: 51

|

To get better flex straight out of the box: 1 - Grind part of the front chassis brace (P/N AX80026A 1) away to clear the servo horn. 2 - Also use the smaller servo mounts (P/N AX80028 6) instead of the taller parts - I have found that these can hang on the chassis rails. 3 - Also as previously mentioned, remove the rubber shocker stops. I found that these 3 three things made a big difference when building the kit version of the Honcho. |

| |  |

| | #52 | ||

| Newbie Join Date: Dec 2009 Location: Layton, UT

Posts: 7

| Quote:

Quote:

| ||

| |  |

| | #53 |

| Rock Stacker Join Date: Mar 2011 Location: by the ocean

Posts: 67

|

wow cant wait to get my honcho. keep going guys im kepping notes |

| |  |

| | #54 |

| Newbie Join Date: Feb 2011 Location: New Brunswick, Canada

Posts: 31

|

cheap links, and 4 link For the dingo scx10 NOT Honcho... I picked up some Traxxas revo push rods with rod ends. $5-$7 a pair they bolt up to the truck the same as stock. are much stronger and look way better. they are the same lenght as the stock links. (11.5" wb) I bought 3 pair. 2 for front lower and 4 for the 4 link in the rear. |

| |  |

| | #55 |

| Newbie Join Date: Apr 2011 Location: Norway

Posts: 45

|

Nice thread guys! Alot of good info for us noobs here.Will do several of them to my honcho Im sur emost of you know this tip but here it goes: If you change the screw in front of the front axle that holds the C hub to a screw with a lowered (is that correct?) head and grind of some of the plastic/metal on youre steering knuckles you will gain a few extra mm of turn. And I made myself cheap steering links out of some plastic rod ends and 3mm threaded pole(whats the correct name for it in english, if you know what I mean?) that wont flex when turning so I got a tiny bit more of turn there too Last edited by josruu; 04-19-2011 at 01:36 PM. |

| |  |

| | #56 | |

| Rock Crawler Join Date: Oct 2009 Location: Columbia, SC

Posts: 536

| Quote:

Another cheap lil thing I did was fab up a mount for the batt. up front with a scrap piece of styrene. Just sandwiched it between the rx box in the rear and between the servo and mount in the front. worked out great with the Hand Bros. mount.  | |

| |  |

| | #57 |

| Rock Crawler Join Date: Jan 2010 Location: Arvada

Posts: 783

|

Hey all, i'm glad this thread is helpful. I hadn't checked it for awhile. I'll work on editing this post soon with some of the changes and cheap mods i've done to my Honcho. Not much but I did waterproof it. Working on doing a CMS mount using the stock servo plate myself. Keep 'em coming guys  Thank You!! Thank You!!

|

| |  |

|

| |