| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Mar 2015 Location: florida

Posts: 300

|

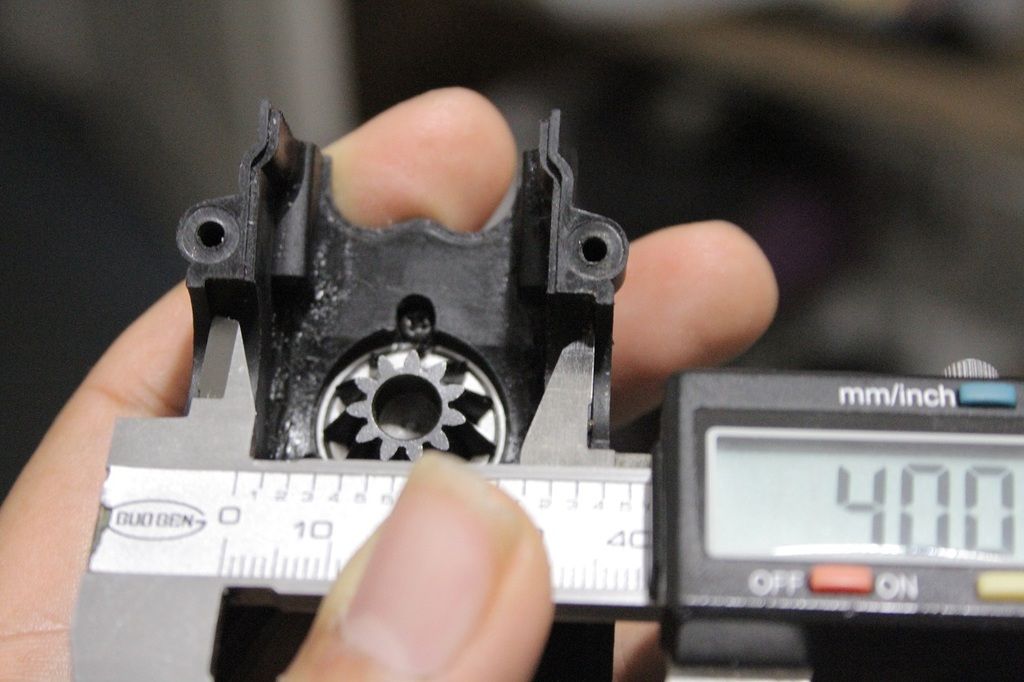

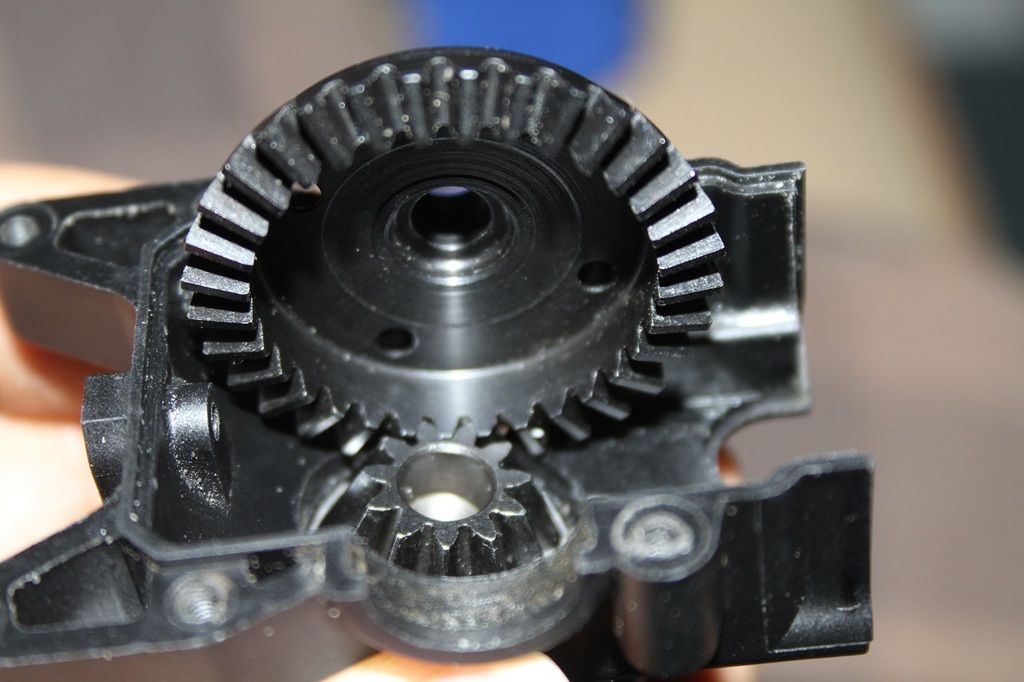

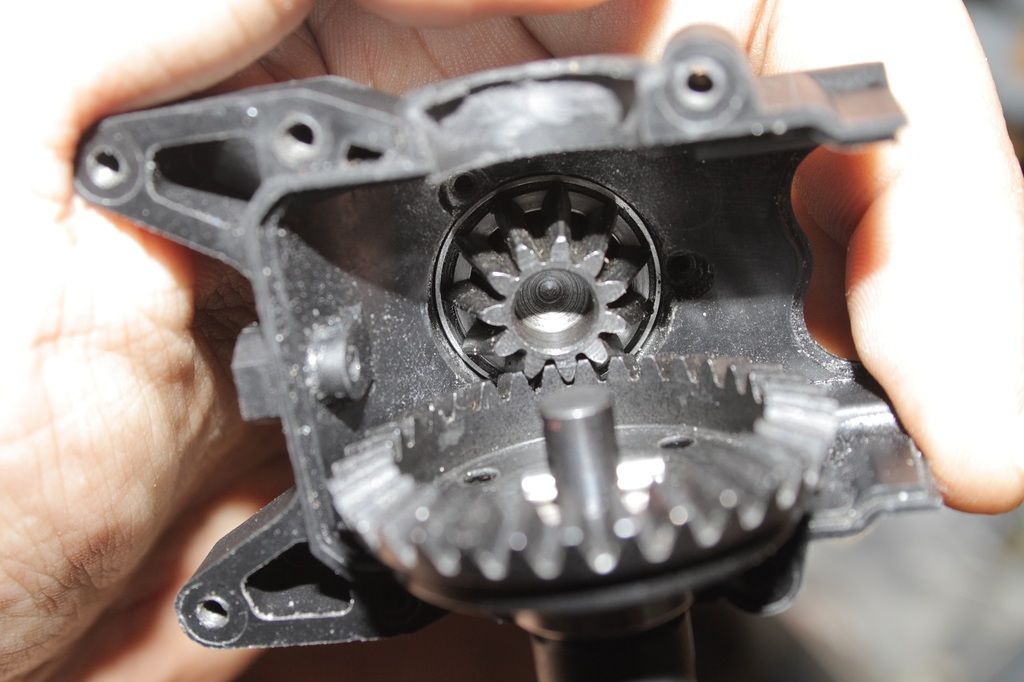

Early yesterday morning I came upon an idea about shimming the bevel gear to close or widen the gap/mesh between the bevel and pinion gear. After a much needed rest I pitched the idea to hardcore bashers, regular users and people who have helped me in the past figure out the mechanics of the YXL suffice it to say I've had mixed responses. But most agree that in order to find out if it will work or not the best way way is just to go with it. A little background before I go on this experiment, I own a YXL RTR I have yet to experience mesh problems on my rig, but also I am building a YXL based F/R solid axle monster truck with 9.6 x 5.9 tires. The each mounted tire alone weights 3.5 lbs and with 7 lbs on each axle you can imagine the strain it would put on the gears. This experiment would be beneficial to the my YXL MT build should the need arise in the future and maybe cross over to the bulkhead too if the experiment prove successful. I would be working on the plastic solid rear axle since its cheaper to replace with the straight gears not the helical ones for the simple reason thats what I have on hand. Here is my idea ever post I come across YXL differential mesh dilemma solves it by adjusting the pinion forwards or backwards. My take is that why not adjust the bevel gear by sanding the ends of the differential bearing mount on the bevel side and put the shims on the opposite side if the mesh is too tight or vice versa if the mesh is too loose maybe both just in case. Correct me if I'm wrong, as I understand it, shimming the front or the back of the differential pinion gear to adjust its gap with the bevel gear. The problem I see when lowering the pinion is less contact surface with the narrow teethed bevel gear also it might mess up the bearing catch on the back of the bulkhead/rear differential. Not so much raising it except hitting the differential case, it is a simple solution given that they are angled gears. The downside to my method is sanding the plastic specially on the solid rear axle it is very tedious at the very least. Sanding plastic material needs to be precise and straight , otherwise it will wobble and create problems and you'll need new parts if you mess up. I'm just amazed no one has introduced this idea, well, until now that is. I mean if this was a transmission gear mesh problem people automatically backs off the pinion for a better mesh/gap between the gears why wouldn't the same principle be applicable with meshing angled gears. Here are some initial photos, I will be uploading more detailed photos soon stock bulkhead marked where I will be sanding  showing measurements of the stock bulkhead  thickness of the bearing mount/catch before sanding  and bevel and pinion dry fit  |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

If your Thread says Bevel/Pinion please use a HD Beveled gears for this experiment ... This manufacture did.. Why did he come out with a V2 for no reason when all he had to do was send extra shims and some sandpaper  your just a BHB Hater  and I don't know why and I don't know whynow I just set back and see if I can learn something because your a smart guy ... yes I am being serious  |

| |  |

| | #3 |

| Pebble Pounder Join Date: Sep 2015 Location: Wa st. Olympic peninsula

Posts: 101

|

Ok I see what you are spouting off about now, for some reason I could not wrap my brain around what you were talking about earlier in the P.M and thought you were talking about sanding off the area where the three screws hold the bearing and pinion in place. So by sanding the bearing hold on the opposite side of the ring gear say about the thickness of a shim or two you will be able to shim the ring gear into the pinion, makes sense now that I see some pics, good idea but precision and tedious patience will be needed, not sure what you could use to remove the material in an efficient and precise manner, and be careful not to make the plastic to thin, but it sounds like it will work if done right : ) |

| |  |

| | #4 |

| Pebble Pounder Join Date: Apr 2015 Location: New Jersey

Posts: 138

|

Agreed jumpit, seems like taking material off of plastic sure is easier than metal but itll come down to precision and sanding just seems innacurate but might work.

|

| |  |

| | #5 |

| Rock Stacker Join Date: Feb 2015 Location: Netherlands

Posts: 81

|

Never mind

Last edited by Sjonnie82; 05-11-2016 at 12:37 PM. |

| |  |

| | #6 |

| Newbie Join Date: May 2016 Location: The hills

Posts: 22

|

I've been wondering about the gear mesh, it seems all the problems I've experienced are because the bearings that hold the diff in place fail. The pinion and diff gears seem fine..... but everyone has an obsession with putting the bevel gears on. What am I missing? Sent from my ASUS_T00G using Tapatalk |

| |  |

| | #7 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

I just finished two HD mods for bashers; pinions are back in the mailbox 2 hrs latter for free.. You would under my frustration with Felix if you followed the series of events.. none the less... I'm sick of the BS... I'll shut my mouth like a good little basher ... BTY it dose say YXL Differential (BEVEL/PINION) B E V E L P I N I O N smart ass (I didn't call ya a dumb ass) |

| |  |

| | #8 | |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

| Quote:

RTR's come with the HD Gears.... Newer Kits Come with HD gears... Can you even perchance straight cut gear sets online still ???? That's WHY...... And I know its a taboo but my HD gears love 6s.... no signs of wear after 75 + runs... | |

| |  |

| | #9 |

| Newbie Join Date: May 2016 Location: The hills

Posts: 22

|

Interesting, my kit is only 2 months old and I got straight cut gears, must have been old stock. Bhb can you post a pic of your mangled gears please I wanna see what happens to them Me and a mate have yeti's, he's given his a load of abuse and mine's fairly new, we have both had front bearing failures, so far the gears are fine Sent from my ASUS_T00G using Tapatalk |

| |  |

| | #10 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

I would but my phone's screen in black so no sending pictures to my PC... I'll report back tomorrow with some ... hopefully

|

| |  |

| | #11 |

| Quarry Creeper Join Date: Mar 2015 Location: florida

Posts: 300

|

Please keep your responses/post on point pertinent to this thread, go start your own thread and discuss what ever you want to.

|

| |  |

| | #12 | |

| Quarry Creeper Join Date: Mar 2015 Location: florida

Posts: 300

| Quote:

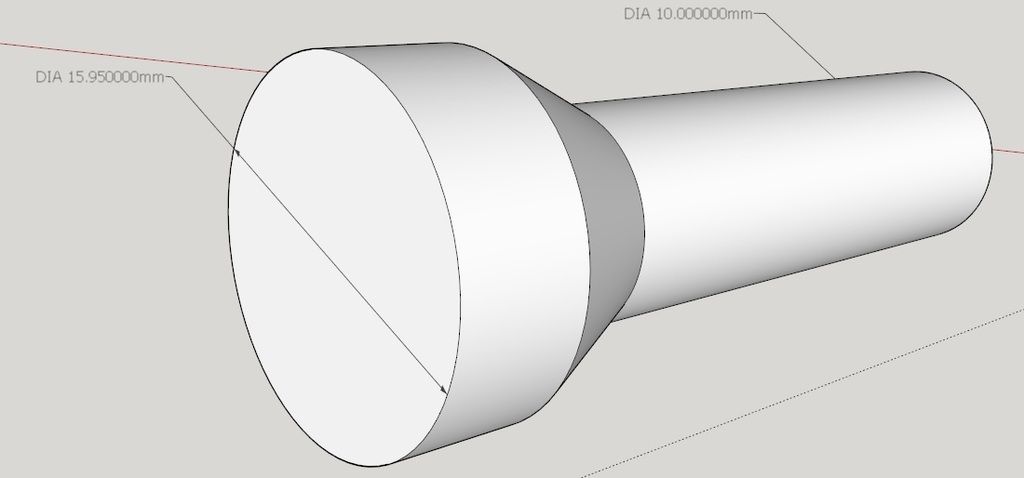

Your right about sanding the plastic too thin, even if it was sanded straight it still needs to be thick enough to support the bearings and withstand the forces being applied to it. Its very easy to mess up plastic working with power tools, but on the upside plastic is cheap to mess with it. Maybe something like this attached to the press and 2000 - 3000 grit sandpaper glued on the end.  | |

| |  |

| | #13 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

Wow

|

| |  |

| | #14 |

| Quarry Creeper Join Date: Mar 2015 Location: florida

Posts: 300

|

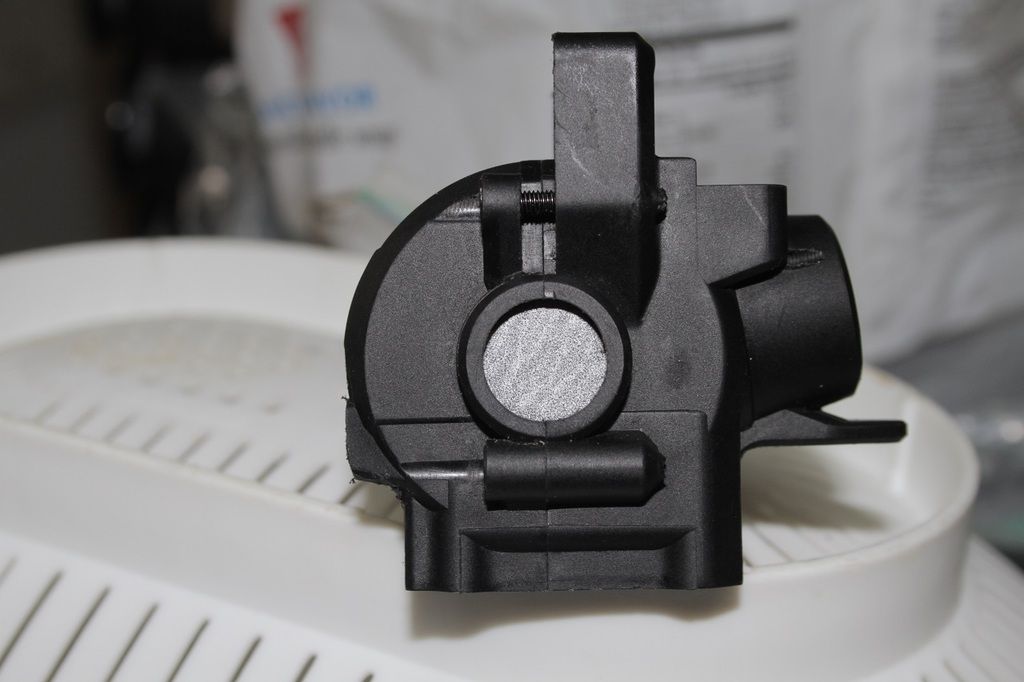

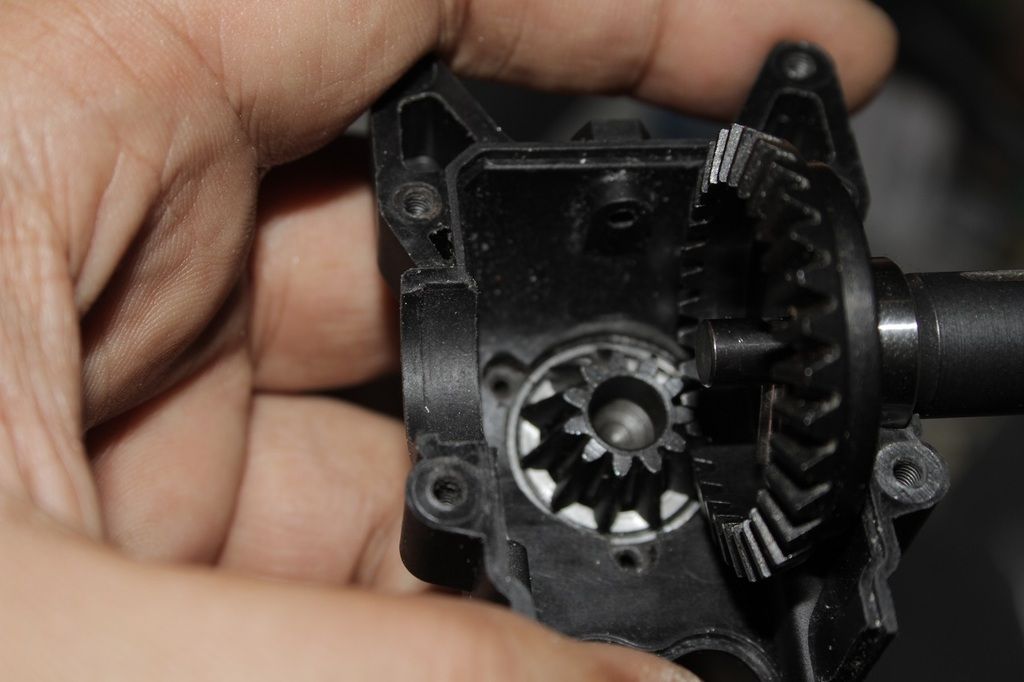

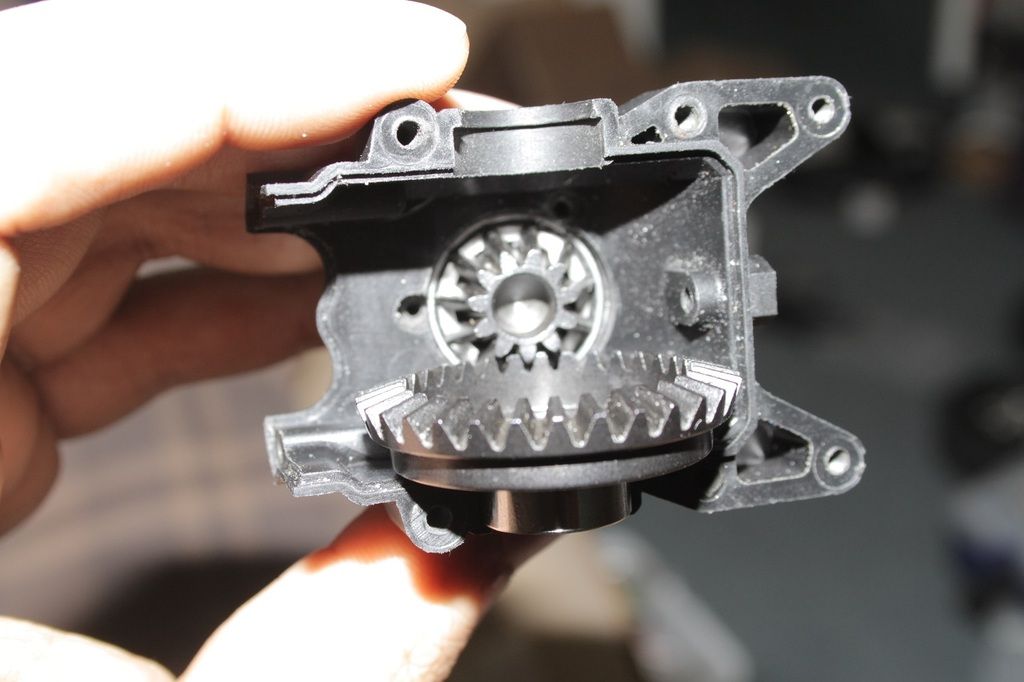

This is the tool I ended up using  here is the side view before the tedious task  here is a view of stock bevel/pinion clearance   First dry fit after a little sanding  after a little bit more sanding      Measurements after the final sanding    Next the solid rear, finally found and ordered the 16 mm x 0.1 mm shims, hopefully I will be done with rear by the time the shims arrive. |

| |  |

| | #15 |

| Rock Crawler Join Date: Dec 2014 Location: friendswood, TX

Posts: 932

|

Way to think outside the box man. I wish you the best of luck and really hope it works for you and others.

|

| |  |

| | #16 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

Excellent sanding implement !! I'm curious to see how it works out with the beveled gears !!

|

| |  |

| | #17 |

| I wanna be Dave  Join Date: Jun 2013 Location: Ramona, CA

Posts: 2,178

|

That's a bad arse little sander you made their. Q? For the learning impaired like myself. Maybe I don't fully grasp what is happening but it looks like the mesh is worse now. Maybe the camera angle or ?? But it looks like just the crown of the pinion and ring are in contact. I know you don't want them smashed together like one piece but again maybe I'm just not getting it. I definitely have some learning to do. |

| |  |

| | #18 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

Ive got waddled out bulkheads from Pre HD mod days that look just like the 4th picture up ... Hopefully you can find a easy way to (Add material (on both halves /one side only) or cap the THIN bearing lobe with a removable washer ) also in my HD gear testing experiences the bearing associating the ring gear was always the one to go first... every time You could thread the outside of the bulkhead output lobe and use a 19mm nut with a washer plate on the end.. Or a cap nut with a hole board for the output... I think the ( thin ) nut that holds celling light fixtures (globe) would work or a electrical box nut.. Should be easy to find !! Last edited by BarHarborBasher; 05-10-2016 at 09:05 PM. |

| |  |

| | #19 |

| Pebble Pounder  Join Date: Feb 2016 Location: Stillwater

Posts: 153

|

The bearing that sits on the ring gear side BHB? If so, that's the same bearing I've had go out multiple times as well. Always that one. Sent from my iPhone using Tapatalk |

| |  |

| | #20 |

| RCC Addict Join Date: Jan 2016 Location: Bar Harbor

Posts: 1,529

|

That's the one with the MOST force.... Right where the excess material is removed... I've got battle wounds in my vanquish from it and my bulkhead driver side output was ALWAYS the first one to start waving at me ... Look I'm effed up again lol

|

| |  |

|

YXL Differential Bevel/Pinion gear mesh/gap - Similar Threads

YXL Differential Bevel/Pinion gear mesh/gap - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Pinion gear and ring gear mesh question | flyboy320 | Axial Wraith | 18 | 01-09-2016 02:41 PM |

| Differential gear mesh (underdrive) | summerof95 | Axial SCX-10 | 10 | 01-05-2015 09:19 PM |

| Bad Mesh on bevel gear and diff gear out of the box? | Elliott000 | Axial SCX-10 | 3 | 08-19-2011 06:37 PM |

| Pinion Gear/Mesh? | 28offroader | Venom Creeper | 9 | 01-26-2011 01:21 AM |

| bevel gear, ring gear mesh | rocksteadily | Tamiya TLT Crawlers | 5 | 05-09-2009 12:04 AM |

| |