| | #941 |

| RCC Addict Join Date: Jul 2008 Location: San Diego

Posts: 1,144

|

I got a Huddy lathe from Craigslist. When I cut a com from the inside to out side its rough. If I cut from the outside the the inside(toward the windings) the smooth. The guy said it has a diamond bit on it. It also came with a bush alignment tool. I cut the coms on both motors and aligned the brushes and the motors seem much smoother. There are both regular Tekin 45t motors.

|

| |  |

| Sponsored Links | |

| | #942 |

| Rock Crawler Join Date: May 2009 Location: Queensland, Australia

Posts: 610

| The tools are only designed to cut in one direction (generally that it towards the windings), that would be why it cuts crappy in one direction.

|

| |  |

| | #943 |

| RCC Addict Join Date: Jul 2008 Location: San Diego

Posts: 1,144

|

Thanks- I didn't get a manual with it.

|

| |  |

| | #944 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

I got a good deal on a Xipp Lathe and decided to cut my first comm....Fantom 35T. I used to use this as a comp motor and it has been beaten into the ground. Here are a few pics....please give any helpful tips! Before:  After a few passes:  Finished:  |

| |  |

| | #945 |

| I wanna be Dave Join Date: Oct 2007 Location: Houston

Posts: 3,761

|

Looks like a hell of a job for your first cut.  |

| |  |

| | #946 |

| Newbie Join Date: Feb 2009 Location: Sacramento

Posts: 37

|

Nice. |

| |  |

| | #947 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Thanks Shelby! Thurzday, actually, after the first cut, I got pissed about the gap and I put a bearing back there.  |

| |  |

| | #948 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

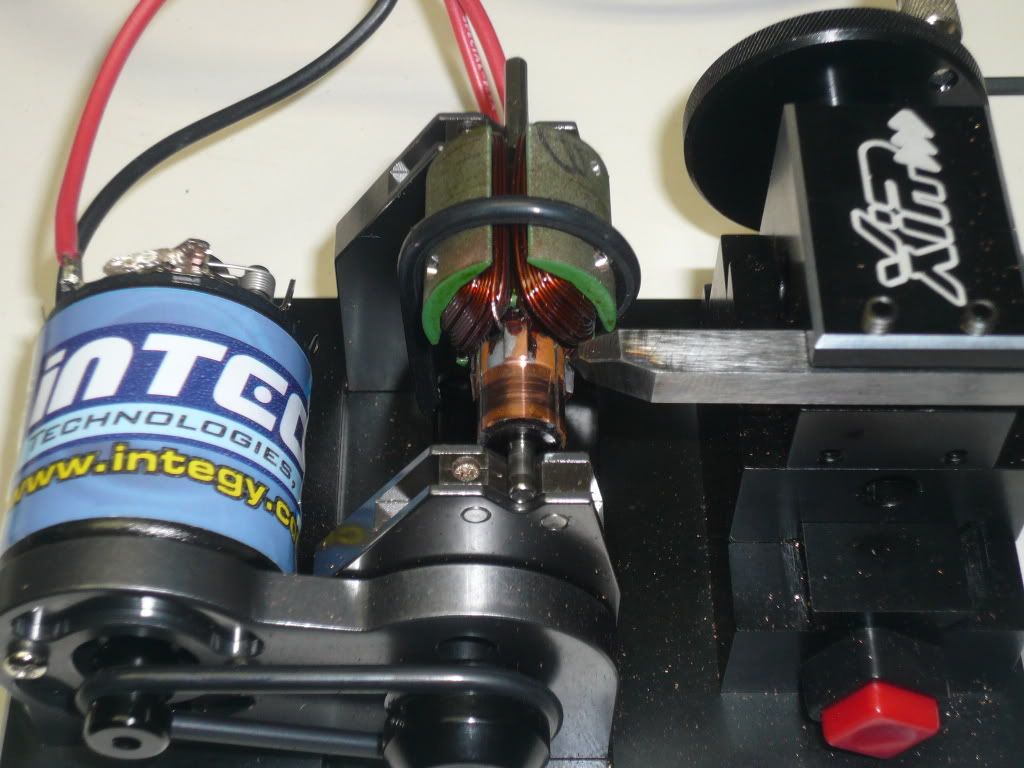

And here is another motor....a 55T Tekin Pro Handwound:   I noticed a few things about this lathe....the far mount (that holds the other side of the arm) is adjustable and I didnt have the bit adjuster tightened down completely.....which was allowing it to walk easily. |

| |  |

| | #949 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

Looks like you need to slow down on the left to right motion.

|

| |  |

| | #950 |

| Pebble Pounder Join Date: Jan 2011 Location: Rochester

Posts: 127

|

alright, this may be useless to some, but I figured as long as I have the equipment someone might be interested in seeing this comparison. With 4 kids including a newborn, I haven't had much time to play with my stuff lately, but finally had some time to take some pictures. I have three lathes (not sure why, they just seem to find me). The first one is a cobra.   The tool holder and motor mount/v-block are separate, so although the base and attached tooling is fairly solid you definitely need to take your time to set it up. I detached the v-blocks from the base slightly to show how they can get "askew" fairly easily.  The second is an Eagle Racing "mod fashion", which I have no idea where it comes from but it's surprisingly solid, and well built.  As you can see the tool holder and the v-blocks are separate, but tied together so the comm and the tool holder are parallel even when the v-blocks are adjusted.  The last is a Hudy. I believe this was their higher end model, because the v-blocks have bearings. This seems like a good idea, but I could see how it could create a problem when the bearings wear. This one is perfect though. The tool holder and v-blocks are linked together similar to the Eagle, to ensure that the comm and tool holder are parallel. The tool holder moves like butter, and everything else reeks of quality.. kinda awful early 90s paint scheme though.   I have yet to use the cobra, but tried out the Eagle and it works great.. I missed out on a trinity lathe last week by a few minutes. No idea why I want them, I guess I just think their neat. The Eagle came with a bag full of old motors, so I have something to practice on. Last edited by marvinbeaverdip; 04-04-2011 at 10:11 PM. |

| |  |

| | #951 |

| Pebble Pounder Join Date: Jan 2011 Location: Rochester

Posts: 127

| same thing i was thinking.. after it was finished, does it feel smooth, or does it feel grooved? When I cut, I take just a hair off at a time, and run the tool as slow as I can turn. My first few comms have come off almost looking polished. Each comm took about 6-8 cuts.

|

| |  |

| | #952 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

The comm looks rough to me. Hopefully you didn't chip the bit. While some bits can cut both ways, those certainly cannot. Make sure you read the manual for the correct cutting direction. As you move the bit across the comm, I don't think you can really move too slow.....better slow than too fast.... I would definitely make sure that bit is not chipped..... Later EddieO |

| |  |

| | #953 |

| RCC Addict Join Date: Jan 2005 Location: Germany north

Posts: 1,669

|

looks like the bit is edged wrong Jeremy or the motor spins in wrong direction or the bit is not right in height Last edited by EGRESSor; 04-05-2011 at 01:43 AM. |

| |  |

| | #954 | ||

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

| I was thinking the same thing. My first motor was much better than the second and I think that I was moving too fast or making cuts that were too deep. The arm looked fine to me until I looked at the picture. Quote:

Quote:

Thanks for the info guys. I am glad I had a few spare motors to practice on. I plan to pull this one out again tonight and go over it again. I am enjoying cutting these arms!  | ||

| |  |

| | #955 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

How far above center did they recommend? Copper doesn't cut well above (below since the bit is upside down) center unless the bit has a good rake to it. I can't tell, but it looks like there is some rake to the bit. Cutting on center still works best. Looks like you are either using a dull bit, it is too off center, or you are trying to cut too deep. The second comm certainly has some smearing, you could have dulled the bit on the first attempt. What voltage are you running on the xipp, and is it a 55t motor? Did you only make cuts going from top to bottom of the comm? |

| |  |

| | #956 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

The instructions just said at center or above if center isnt possible. I was using a 3S lipo that was at about 10.5V and yeah, I believe it is a 55T motor... What would dull the bit? How often should they be replaced? Any advice on where to get one? McMaster? |

| |  |

| | #957 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Ok, I made a few changes to the lathe....lowered the bit (it is now just a hair above center) and slowed the cross motion down as much as I can while still keeping a constant motion. The cuts seem to be a lot nicer to me. This is an old Tekin 55T Machine Wound: (sorry for the crappy pic, I was having trouble getting my camera to focus properly)  What do you guys think? I also went back over the previous motors and they are now about the same as the above comm. |

| |  |

| | #958 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

Looks better! Once you get that sweet spot on the lathe set up it will be easy cutting. Kinda gets addicting! McMaster is my choice for bits.

|

| |  |

| | #959 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

Kinda addicting? How about totally addicting.

|

| |  |

| | #960 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Yeah....no kidding..... Gonna try a motor now that should be nice and beat up....it's in my on road racer, that I've never jacked with. |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/electronics/223989-cutting-motor-commutator-motor-tweaks.html | ||||

| Posted By | For | Type | Date | |

| Hiilimoottorin kunnostaminen | This thread | Refback | 10-04-2011 03:19 PM | |

| |