| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

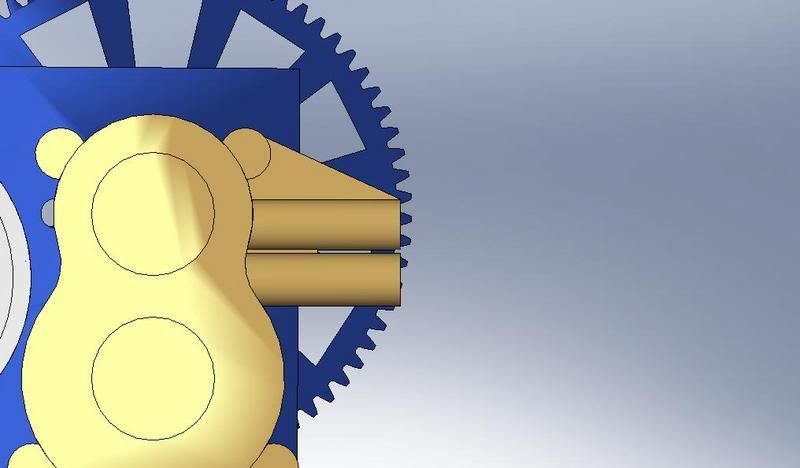

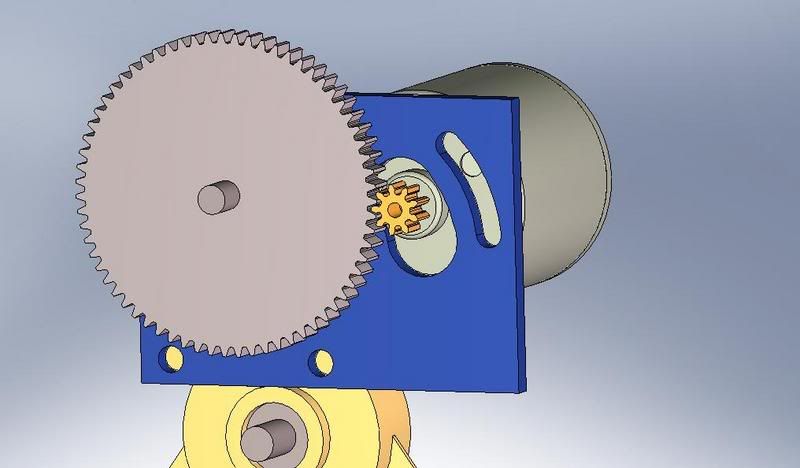

Thank you for the info. Little things like that help the most. I will double check to make sure I don't have any clearance issues with using a 67t spur. Since these will most likely be used in custom chassis' I don't see a huge problem with having to use a spacer but it will also be nice to let people know.  I am going to create several gears tonight and test fit them. I need a bunch of suggestions for gearing. 72/10 72/12 72/9 67/9 ??/?? Let me know what you guys want to see fit. Thanks again. Josh |

| |  |

| Sponsored Links | |

| | #22 |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

|

I don't have any issues with my 67t spur.Anything bigger and I would have to shim the tranny to get it to fit.

|

| |  |

| | #23 | |

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| Quote:

EDIT: Looking great Harley!!! As for gearing...my TLT 2.2 uses 12/87...but as I said don't remember the axle gearing in the TLT and WK. JIA'sDad, Great lookin motor plate too!!! Last edited by Natedog; 04-04-2007 at 04:34 PM. | |

| |  |

| | #24 | |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

| Quote:

| |

| |  |

| | #25 |

| Rock Crawler Join Date: Jan 2007 Location: Midway

Posts: 836

|

I'm running the 32 pitch, 72t spur w/ 9t pinion and powered by Mamba 25 w/ a 450 park brushless motor. Power to spare and I can walk and keep up with it. I have not calculated final ratio. Any slower would maybe not have enough wheel speed. But I have found a 100 tooth spur gear. Have not bought it yet.

|

| |  |

| | #26 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

I test fitted a 67t spur with a few different pinions, all fits fine. My question is do you think it is a big deal to have one of the motor mount screws behind the pinion? I am thinking I will probably need to change it. Just sucks to do.  |

| |  |

| | #27 |

| Rock Crawler Join Date: Jan 2007 Location: Midway

Posts: 836

|

Do you mean behind the spur gear. =big gear, pinion=little gear. If the spur? If you are going to make a new mount which is what your doing, I would prefer to not have a screw behind a gear. But it really is not a big deal to me.

|

| |  |

| | #28 | |

| 06 Super National Champ  Join Date: Jun 2004 Location: Stark Industries Bar and Grill

Posts: 11,361

| Quote:

If you can put a motor mount screw behind the pinion...I want to see it. Don't worry about it behind the spur - they're not solid like in your rendering.  | |

| |  |

| | #29 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

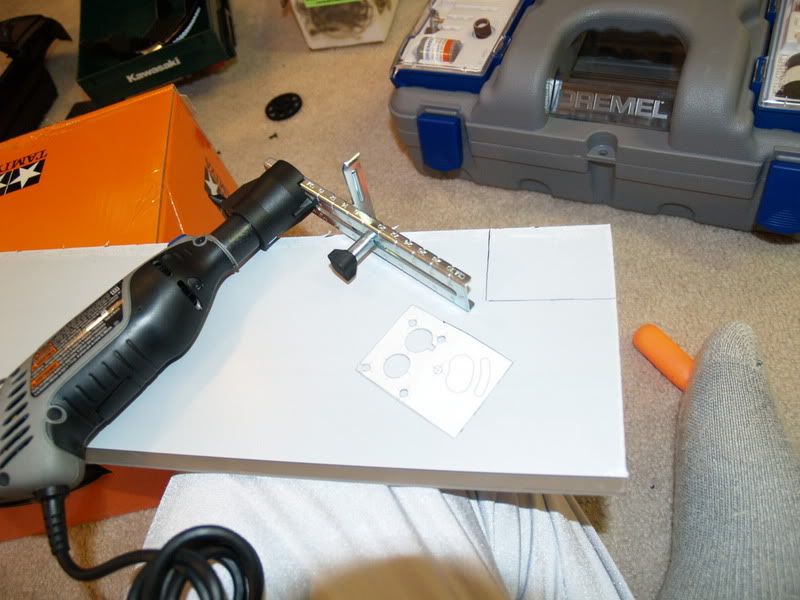

Dang it, yeah I meant spur. Thanks for pointing out I'm an Idiot, jk. I have been mixing them up all day, well anyways. I picked me up a new Dremel last night (400 series baby) and I am going to try and get a couple of these cut out of 1/8" delrin tonight. I am going to send one back with the tranny when I return it to GStealer. I will try and post up pics tonight if I get it done. I have to run to Fantastic Plastics over lunch to see if they have a scrap I can buy instead of spending $70 on a 24 x 48 piece. Peace out. Josh |

| |  |

| | #30 |

| Rock Stacker Join Date: Jun 2006 Location: Harlem

Posts: 83

|

Here is my scale truck chasis with WK trans with stock plate modified to reclock it.worked pretty good. |

| |  |

| | #31 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

Today when I was cuting out the template for the new clocked motor plate I noticed that it printed smaller then 1:1. I checked the paper template against the design and concluded that Adobe PDF Maker actually shinks the print by almost 5%. So I corrected the output size and everything should be good now. This is the reason why the servo mounts were not lining up 100% correctly (more like 96% correctly). With things this small it can really cause a problem. Anyways, a template is available for anyone who wants it. Josh |

| |  |

| | #32 |

| Quarry Creeper Join Date: Mar 2007 Location: Syracuse

Posts: 384

|

I'd like a template, could you PM it to me?

|

| |  |

| | #33 |

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| That doesn't bother me...as pointed out there are holes in the spurgear. Function over form! A hole could be drilled in the spur if needed to make it easier.

|

| |  |

| | #34 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

The template can not be PM'd. It has to be e-mailed, just send me an e-mail and I will reply with the template attached. I was going to try and make one tonight but I can't use my new Dremel untill next week (long story). Hope to see some response to this. It should be pretty easy for everyone to make with a dremel and a drill bit. I recommend using some plastic and a rotozip blade. I bought a piece of plastic today that would make probably 30 of these things for $2 (scrap pile at Fantastic plastics). BTW, I am not going to make 30 of them, I was just saying that I only spent $2 for that much material. Josh |

| |  |

| | #35 |

| Quarry Creeper Join Date: Mar 2007 Location: Syracuse

Posts: 384

| |

| |  |

| | #36 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

You got mail. But for future reference, please click on my user name and click send e-mail. Much easier for me, don't have to cut and paste ya know (I can be a lazy a$$ sometimes). Josh |

| |  |

| | #37 |

| Quarry Creeper Join Date: Mar 2007 Location: Syracuse

Posts: 384

|

No problem, Ill post pictures of my project very soon in this thread! Thanks a ton! |

| |  |

| | #38 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

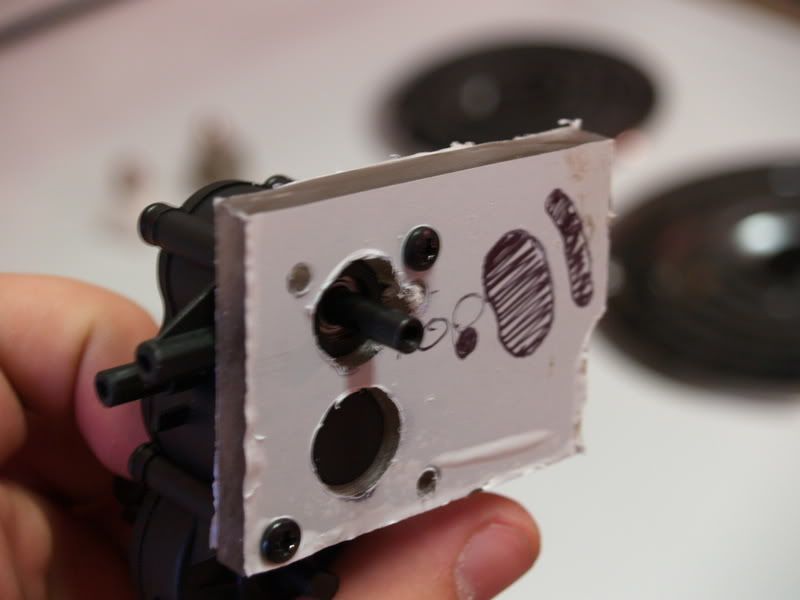

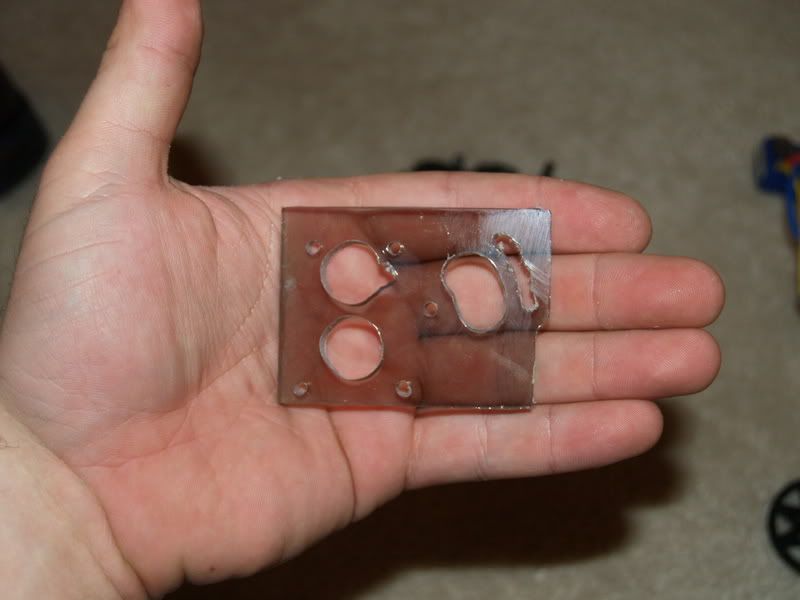

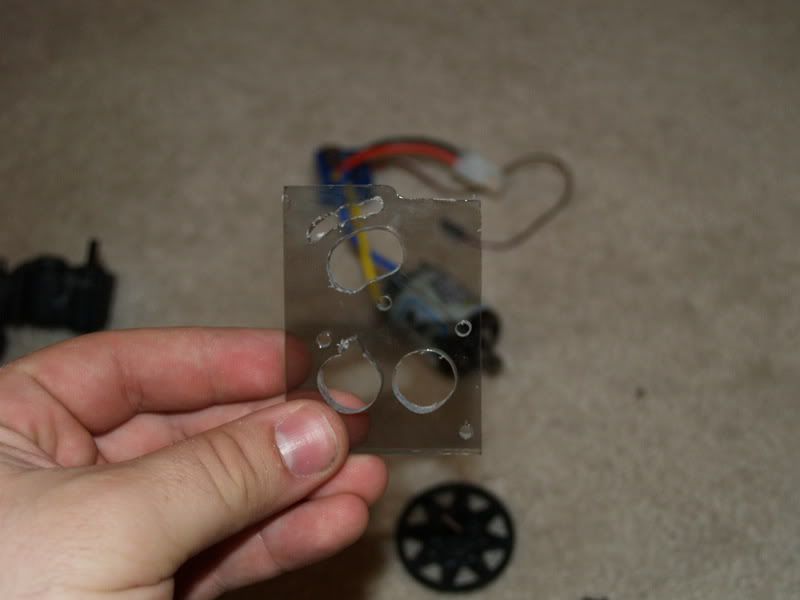

Well decided to make one of my plates today when I got home. Here is a pic of the Final Product but the fabrication is below.  Started at around 6:15 or so. It took about an hour to finish, and I took a lot of pictures along the way. I feel it went really quickly. Simply cut out my the paper I printed out, and traced it onto the palstic and began.  First I used a Rotozip blade on my new Dremel and cut out the basic square. It didn't work that well so I used a hack saw, which worked very quickly. I then cleaned it up quick on my bench grinder.  Traced the wholes where the mounting points and shaft carriers went. Used a drill bit to drill several quick holes, then cut through the remaining material with the rotozip.   Then I test fitted the plate onto the tranny.    Last step was to cut out the the holes for the motor to mount through.  DONE!!!!!!!!!!!!! Here are the pictures to show the amount of adjustment. I did not go purchase nor did I have the proper size pinion and spur combos. And this is a borrowed tranny, GStealer sent me his so that I could model it and design this plate. I big thanks goes out to GStealer for paying postage to get the tranny to me and letting me use it to design this. I hope that many of you will find this template useful, I spent quite quite a little bit of time on this little project. So anyways.........................lets finish up the pics.            Thanks Fellas Josh Thiede |

| |  |

| | #39 |

| Quarry Creeper Join Date: Jul 2006 Location: Ontario, NY

Posts: 254

|

Looks great!! Nice job!   No biggie one sending it to ya.. really. Glad to help. |

| |  |

| | #40 |

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

|

Anybody running this setup with the motor down next to the chassis skidplate? I'm considering this and have a couple ideas for tranny mounts already using crossbraces off the motor mount to connect to the chassis vertical plates. Otherwise I'll just let the motor sit above the tranny near the middle of the chassis...which creates a slightly higher CG

|

| |  |

|

| |