| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

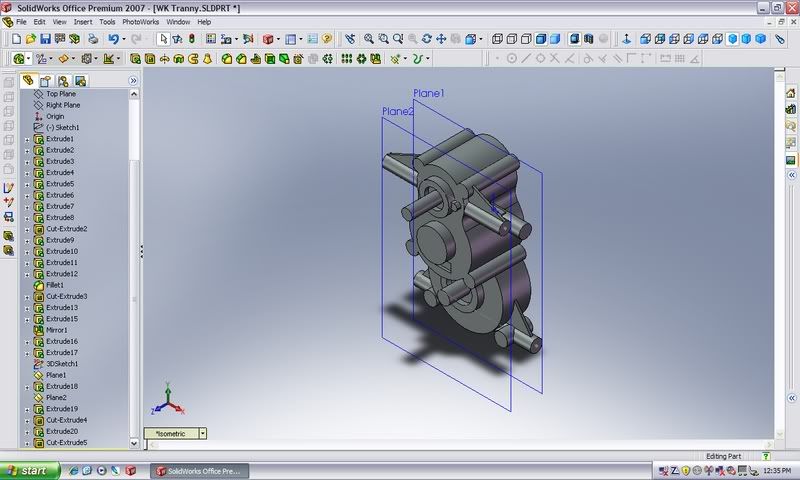

I am working on a template for making a clocked motor plate for the wheely king. GStealer gave me the idea and set me his tranny to so I could model it. I got the tranny modeled during lunch, so I will start on the plate a little later. Again this will be like the servo mount, I will just make a 1:1 template that you can trace and make your own plate. Here is the start.   It will be designed around a 55T lathe, so just about any motor should work. Last edited by Harley; 10-09-2012 at 03:38 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Jul 2006 Location: Ontario, NY

Posts: 254

|

Wow, that got there quick! Some fast work in getting that done too.. Looks great!  Feel free to hold on to it until you're sure you're done. I'm stuck on my build anyhow.. |

| |  |

| | #3 |

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

|

Lookin good...again. Last edited by Natedog; 04-20-2007 at 02:44 PM. |

| |  |

| | #4 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

Just incase anyone is wondering, this is not being designed for the stock chassis. I do not know that there is room for it in there. I do not own a WK yet so I am not 100% if it is possible or not. This has the custom builder in mind. Josh Thiede |

| |  |

| | #5 |

| Pebble Pounder Join Date: Sep 2006 Location: Minnesota

Posts: 154

| There's NO room to move the motor sideways, the stock chassis is pretty narrow. You can tell by the mounting posts sticking out the side how narrow it is, the chassis plates bolt directly to those.

|

| |  |

| | #6 |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

|

I just put a WK tranny in my scaler.The only way to clock it was to remove one of the mounting posts so clocking one in a stock WK chassis will be hard without a new mount.When you clock it I first tried 90 degrees but when I mounted a 45t motor I actually needed to rotate it about 95 degrees.THis lets the motor rest in the "valley" in the case between the two upper gears.With my tranny I just shaved off all the mounts and made a plate to mount it.Works pretty good.Only thind I had to do was get a larger spur so that it would mesh with the pinion.Ended up with a 32p,67t spur and a 10t pinion.Works pretty good.

|

| |  |

| | #7 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

That is pretty much the plan. The mounts obviously have to be shaved on one side. I have not yet decided yet about mounting. I may make a version with a bend in it for a mounting position, we will see. Thanks for the input, the more the better. Josh Thiede |

| |  |

| | #8 |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

|

Here are a few pics showing how I did it.In the 2nd pic I rotated the motorplate about 95 degrees on the "X" axis. I then made a "L" bracket to mount the tranny to the chassis.I tried to make it a one piece motor/tranny mount but because of my frame I had to do them individually.    |

| |  |

| | #9 |

| Rock Crawler Join Date: Jan 2007 Location: Midway

Posts: 836

|

Harley, Here are a couple of pics of the mount we made for the Scorpion King. Thanks go out to Jeremy for his help on this mount. Hope they help this mount is fairly rough not exact size holes but works well.   |

| |  |

| | #10 | |

| RCC Addict Join Date: Dec 2004 Location: HELL.....

Posts: 1,576

| Quote:

man that a sweet motor plate. especially considering its made of a leftover tlt chassis plate. lol | |

| |  |

| | #11 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

Hey thanks for all the pics guys, I will be trying to get it as compact as possible. I will be trying different spur gear sizes as well. What size spur gears are you all willing to run. The larger the better!!! ASAP please. Josh Thiede |

| |  |

| | #12 |

| Quarry Creeper Join Date: Mar 2007 Location: Syracuse

Posts: 384

|

I'd start with a 90t Spur. Thats what I have in my WK and it works great.

|

| |  |

| | #13 |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

| |

| |  |

| | #14 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

I was thinking that a 32p gear would be the best solution also. The 48p just makes like a little too difficult size wise. I didn't get as much done last night as I wanted to the wife needed some quality time, and you have to try and keep them happy ya know. I will get a good jump on it during lunch. Josh |

| |  |

| | #15 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

I am going to try a 23p 72t pinion, any objections? Too short?

|

| |  |

| | #16 |

| Rock Crawler Join Date: Jun 2005 Location: Safety Harbor

Posts: 588

| |

| |  |

| | #17 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

Sorry I transposed the numbers that is supposed to be 32p not 23p my bad. The design will be up shortly. Josh |

| |  |

| | #18 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

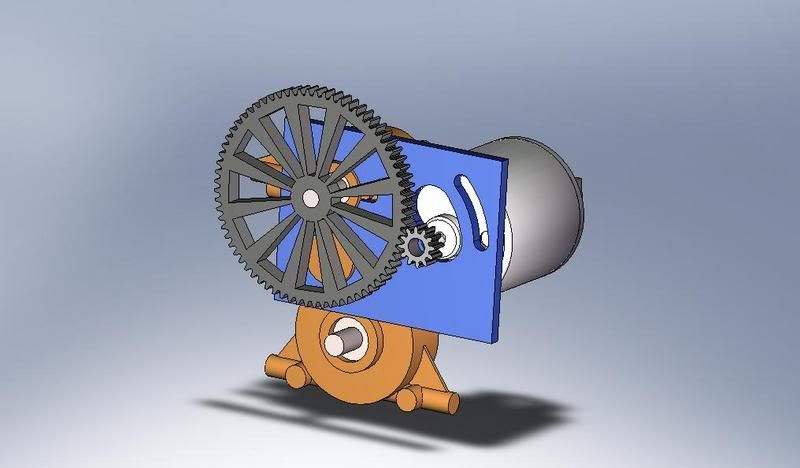

Well here is a quick pic for you all. This is initial design, right now it is setup with 32p 72t spur, 10t pinion, and an integy lathe motor. I still have to put the holes in for the mounting points to the tranny but that will only take a few minutes. I am also going to "trim the fat" off of it too, try and get it compact yet plenty strong.  Lets hear some comments and suggestions. Josh Thiede |

| |  |

| | #19 |

| Newbie Join Date: Mar 2007 Location: Utah

Posts: 11

|

I am running a 48p 96t Robinson racing spur, which allows for a 17t pinion on the stock mount.

|

| |  |

| | #20 |

| Rock Crawler Join Date: Jan 2007 Location: Midway

Posts: 836

|

Harley, a 72 tooth spur sticks out past the tranny mounting post (that the screws go into) a 67 tooth will clear. I know this because that's what I run (72) except I use a 9 tooth pinion. With a 72 tooth I use a 1/4 spacer to clear but the actual amount to clear is about 1/8". pics first shows tranny leaning backwards    Last edited by JIA's Dad; 04-04-2007 at 01:14 PM. |

| |  |

|

| |