| | #21 |

| Rock Crawler Join Date: Jul 2008 Location: grand rapids, bay area, nyc.

Posts: 945

| |

| |  |

| Sponsored Links | |

| | #22 |

| Newbie Join Date: Jul 2008 Location: 'ON THE ROCKS'

Posts: 12

| |

| |  |

| | #23 |

| Newbie Join Date: May 2008 Location: NorCal

Posts: 6

|

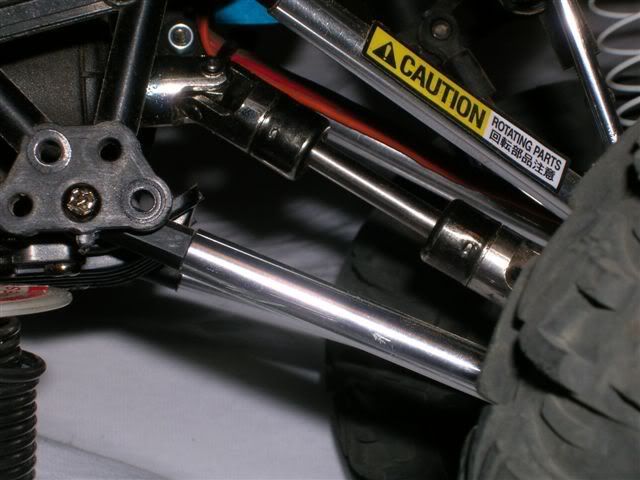

Picked up the Hot Racing center shaft for the cr-01. the look is not as cool as the Punishers but it's significantly less expensive. Should still perform better than OE. Aluminum and steel in a universal joint/sliding dogbone sort of construction.

|

| |  |

| | #24 |

| Newbie Join Date: Jul 2008 Location: 'ON THE ROCKS'

Posts: 12

|

No topcad shafts - sold out...:-( anyone bought a pack - how are they?? |

| |  |

| | #25 |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

| |

| |  |

| | #26 |

| Newbie Join Date: Jul 2008 Location: Westminster

Posts: 26

|

I just got a pair of hot racing shaft and installed them. Good build quality will see how they last. Will keep you posted. Shaft link RM "Do not take life too seriously.....You will not get out alive!" |

| |  |

| | #27 |

| Newbie Join Date: Aug 2008 Location: Anytown USA

Posts: 7

|

Someone on the TamiyaCrawling forum said that the drive shafts from the Tamiya Hi-Lift can be fitted:  I've already stripped out the stock plastic rear shaft, so hopefully the hi-lift pair I bought on eBay will do the trick, TamiyaCrawlers Thread: http://www.tamiyacrawlers.com/forum/...hp?t=54&page=2 |

| |  |

| | #28 |

| Newbie Join Date: Jul 2008 Location: 'ON THE ROCKS'

Posts: 12

|

cheers guys...  |

| |  |

| | #29 |

| RCC Addict Join Date: Sep 2008 Location: Philadelphia, PA

Posts: 1,048

|

The Hot Racing ones look interesting, that dude ships for 99 cents too haha!

|

| |  |

| | #30 |

| Quarry Creeper Join Date: Sep 2005 Location: Sandy, UT

Posts: 368

| |

| |  |

| | #31 |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

|

Finally got mine, the topcad are all steel workings, with a alumnium outer sleeve that must hide the pin(s) that stop the shaft from sliding all the way apart, there's only one set screw per cvd joint holding the pin from coming out, I will be adding a second set screw shortly. Oh and they only give you 2 set screws/pins to attach the shafts? even though you need 4? hopefully they are the same pitch. Last edited by Joat; 09-16-2008 at 11:42 PM. |

| |  |

| | #32 |

| Rock Stacker Join Date: Apr 2008 Location: Vienna

Posts: 65

|

i use a e-savage driveshaft. if you use a driveshaft, that serves as axle on a e-savage you have to shorten and shave the shaft, but it is very beefy. i didn't try to use the shaft between the clutch and the diff, but that should be a better fit. sioncerly tomancik |

| |  |

| | #33 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| |

| |  |

| | #34 |

| Pebble Pounder Join Date: Sep 2008 Location: chicago (now in MD)

Posts: 122

|

Are the punishers not good? I just found out I twisted my stock shafts.

|

| |  |

| | #35 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

The fact that they're "not breakable" means something else is going to break, and that means either something inside the transmission, or inside the axles. Both of which will require you to tear a lot of the truck apart to fix it. And it'll probably cost more than a set of new Traxxas shafts.

|

| |  |

| | #36 | |

| Quarry Creeper Join Date: Aug 2008 Location: UK

Posts: 243

| Quote:

How did you cope with the weird e-savage yokes? Did you just stick with the stock ones, or modify the holes to use the yokes fitted on the savage shafts? | |

| |  |

| | #37 | |

| Quarry Creeper Join Date: Aug 2008 Location: UK

Posts: 243

| Quote:

I wondered about this as soon as I acquired my Hi-Lift, and noticed the shafts. I might try these this weekend, and save my e-savage ones for when I have a little more time. Anyway, I've read around, and nobody seems to have tried this, so here is my fix for the stock shafts: The reason they twist is because they are unsupported. The front shaft twists more than the rear, because the front shaft needs to be longer than the back, but because the components of the shaft (the core and the outer parts of the shaft, that slide in and out of each other) are the same size, more of the splined shaft is exposed. What I did was take one of the spare outside shafts provided in the kit, and cut a piece of the tube off it. I then slid that piece onto the exposed part of the core shaft on the car. I think I used about half an inch or so. You just need to measure the minimum length of the driveshaft whilst fitted to the car (flexed in all directions to check), and the part of the core shaft that is still exposed at minimum is how much outer shaft you need to add. I think I added a little under half an inch, but I'm at work and I can't remember. The piece you add can just run freely on the shaft, as all it is doing it reducing the amount of exposed, weakened shaft. The only caveat is that you need to do this whilst you still have an untwisted front axle. Once the axle becomes twisted you won't get the additional piece of outer shaft onto it. But it is an entirely free modification, that only takes a couple of minutes to do, and so far seems to have lengthened the potential lifespan of my shafts considerably. Once you've done that, repeat it with the back shaft if necessary, but it might not be; the back shaft isn't set as long, and doesn't expose itself to the same vulnerability as the front. I know this isn't clear, but I'll post pictures when I get home. Apologies if someone else has already suggested this idea. Last edited by fatwoul; 09-19-2008 at 04:46 AM. | |

| |  |

| | #38 |

| Newbie Join Date: Nov 2006 Location: Poquoson

Posts: 30

|

I put an Esavage drive shaft in the front of mine and have not had any problems. The rear have not given me any issues yet. I also bought the 3racing shafts if I need to use them at a later date. |

| |  |

| | #39 |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

|

Ok after installing my topcad shafts , there rear is ok, but there a problem with the front shaft, both shafts are the same length- so I tried with all my might to modify a drive shaft to fit the front properly, and it just aint gonna give full front suspension travel without pushing very badly against the planetary gear box, or the front will loose almost a 1 inch of travel, plus it's just a freaking pain to attemp. I shortened 1 topcad drive shaft approx 1/4 inch, this means a full disasemble, outer aluminum sleeves must come off to (1) remove the slider pin (2) lengthen the slots to allow the shaft to collapse since you need to shorten it, not fun and it does not even give you any of the tavel back. To gain travel back I recut the angle on the female side of the cvd sections, I only was able to get another 1 degree back on either end without weakening the joint to much as cause it to snap, I barely got 1 degree on either end, but still missing 3/4 of an inch in travel. The other way to is to narrow the the center part of the male side of the cvd- even then not gonna give you even angle to give you full travel back. So I am still stuck using a shorten jato shaft up front , and using a topcad in the rear. |

| |  |

| | #40 |

| RCC Addict Join Date: Feb 2008 Location: tauranga north island new zealand

Posts: 1,786

|

I used traxxas half shafts,the one from the diffs to the wheels on a stampede.As EeePee said you stil want the shafts to be the weakest part to save the driveline ,people are breaking pinions in axles. I used the cr yoke and ball and made it fit the shafts,works well. |

| |  |

|

| |