| | #21 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

Looking good so far. It's going to be completely different rig than before.

|

| |  |

| Sponsored Links | |

| | #22 |

| RCC Addict  Join Date: Jun 2005 Location: St. Albans

Posts: 1,441

|

Side plates look good naked too  Seeing it like that just makes me want the cab setup even more... Seeing it like that just makes me want the cab setup even more...

|

| |  |

| | #23 | |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

| Quote:

Was thinking about getting the d3 but I have 0 experience with bl motors need someone that does to test it out.... | |

| |  |

| | #24 | |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

Funny you mention the D3 ..... Im re-wiring mine this week and trying one of those out. Ill let you know how it works out. | |

| |  |

| | #25 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

|

That's even better... was willing to order and send one out to you or who ever wanted to try it, so we all could get some feed back... Looking forward to seeing what you think  |

| |  |

| | #26 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

|

While this is out is there any tips, tricks or must do's.... Looks to never been used...  Plan on ordering rcbros. motor mount... |

| |  |

| | #27 |

| RCC Addict  Join Date: Jun 2005 Location: St. Albans

Posts: 1,441

| I use the RCBros motor clamp too. I like the lightweight shafts and slipper eliminator as well. I also cut some little shims out of a beer can to take the slop out of the dig forks... I cant remember who's tip that was though, and I'm not sure if Ive ever seen a write up or pics on it. It was just a few posts in someone's thread.

|

| |  |

| | #28 | |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| Quote:

Also, its a personal thing but I take off as much plastic as possible. I would defiantly remove the front cover and then depending on your preference I like to cut the front of the trans off except the part that holds the spur shaft and I also remove as much as possible from the dig mount just to save some weight. I really like not having a front cover though so I can see whats going on at all times and its easier to troubleshoot. Toyo496 also had the idea of drilling holes around the dig plates and counter sinking them to reduce drag on the dig forks. I have not torn down my trans yet but when I do I will be trying this. | |

| |  |

| | #29 |

| Rock Crawler  Join Date: Oct 2010 Location: triad

Posts: 634

|

Erik, i was going to run with the front cover off also to reduce some weight, but i was worried about debris getting in the gears. Are you not worried about that?

|

| |  |

| | #30 | |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| Quote:

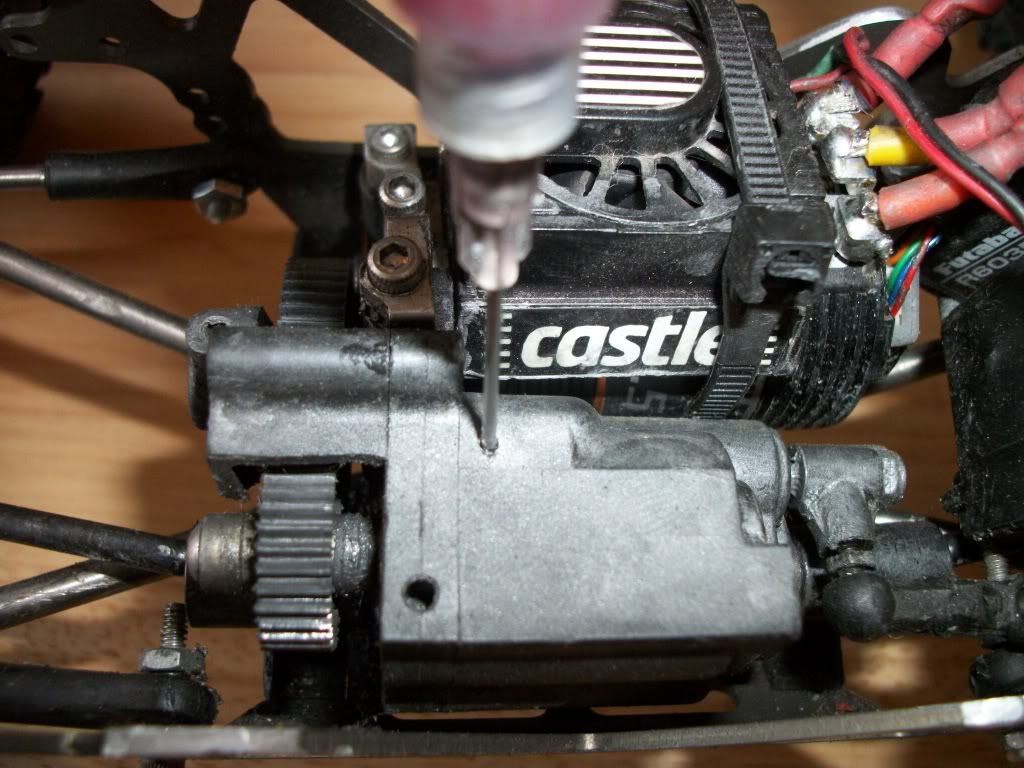

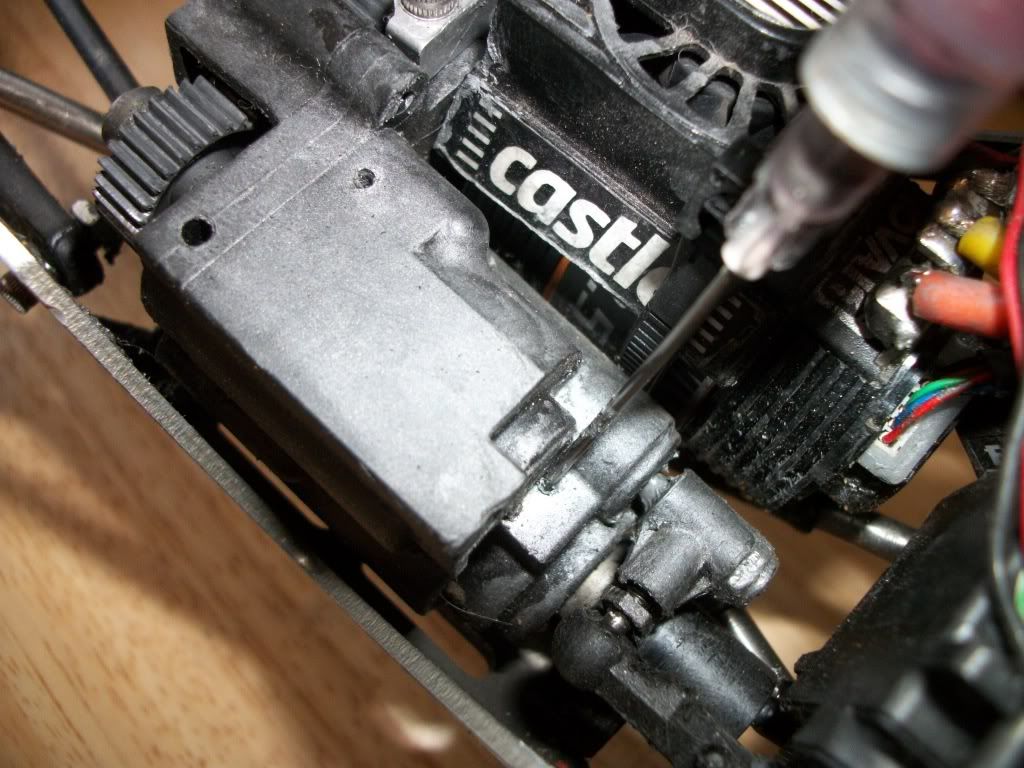

Shots of the holes drilled in the trans.   | |

| |  |

| | #31 |

| Rock Crawler  Join Date: Oct 2010 Location: triad

Posts: 634

|

Word! See ya cover.....

|

| |  |

| | #32 | ||

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

Quote:

wired it up last night and just 10 minutes of basement crawling I cant wait to get it out on the rocks. Ill have more up this weekend after some practice time thursday night. | ||

| |  |

| | #33 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

| |

| |  |

| | #34 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

|

[QUOTE=Erik D_lux;2882648]Not concerned at all. I have been running this way for 100's of hours and months without issue. Plenty of dirt too. Shots of the holes drilled in the trans. /QUOTE] Safe to drill while together? |

| |  |

| | #35 |

| RCC Addict  Join Date: Jun 2005 Location: St. Albans

Posts: 1,441

| x2. Is it the weekend yet???? Dang... still Tuesday. Vertec, what width are those VPs and what hubs did you go with? I'm thinking of going to the knuckle weights and ditching the DHs Ive got on the front of mine to free up some more room for more weight. |

| |  |

| | #36 | |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

| Quote:

Liking ur new avatar! | |

| |  |

| | #37 | |

| Rock Crawler Join Date: Oct 2007 Location: Grants Pass

Posts: 806

|

[QUOTE=Vertec;2884049] Quote:

On a side note why are people wanting to fill their tranny with grease to the point of needing ports? I understand lightly lubing it and a lil on the dig forks, but why pump it full until you are just creating more rotating resistance and weight? I know the worms like a nice bath of grease to work in but why the dousing of the standard tranny gears? | |

| |  |

| | #38 | |

| Rock Crawler Join Date: Oct 2008 Location: Sandy, OR

Posts: 672

|

[QUOTE=highlandcrawler;2884188] Quote:

Yeah, I can't understand that much grease in the tranny. A light coating on the dig forks and maybe the plates and gears, but that is it. I have never had any issue with the tranny that would require this, and I know I am not easy on my rig. | |

| |  |

| | #39 |

| RCC Addict  Join Date: Jun 2005 Location: St. Albans

Posts: 1,441

| Thanks man. It was time for a change... and who doesnt like nice tits? I run .7s in the rear of my truck with rovers. I think a tire like the boss claws would benefit from a wider wheel to keep the nice contact patch.

|

| |  |

| | #40 | |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

|

[QUOTE=Vertec;2884049] Quote:

When drilling something together like this I like to drill 90% through while holding a vacuum next to where I am drilling. Then make sure all the chips are away from the hole and finish the hole while still holding the vacuum. I dont think hardly anything gets into the trans and if it does its just plastic dust/small chips. It would just get eaten and used for lube anyway. | |

| |  |

|

| |