| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #101 |

| Rock Crawler Join Date: May 2004 Location: DFW, Texas

Posts: 662

|

So I've been following this thread reading every post and doing my research. I decided to go ahead and get the Proxxon.  Of course not even 5 minutes after I placed my order I found another band saw that seems very similar and a little cheaper. It's made by Inland, costs around $200, and does wet cutting as well. It even comes with the coolant tank built in and included in that price. You have to buy the coolant tank separately with the Proxxon. Or make your own like Joat did. I'm not saying I regret my order, but I think I could have saved a few bucks if I went with this one. Does anyone have any experience with Inland? Proxxon seems to make very good quality tools from what I have seen but I have never heard of Inland. Here's a link: http://www.whittemoredurgin.com/indbwetdryba.html  |

| |  |

| Sponsored Links | |

| | #102 | |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

| Quote:

| |

| |  |

| | #103 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

very nice looking . Joat, that would be for tile than. You want the ball bearing glide right? thanks. |

| |  |

| | #104 |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

| Yes ball bearing guides as much as possible,I am not sure if you could convert it ?, or how good the motors are, the proxxon is brushless I believe and once you set the rpm , if it slows down the saw will adjust the speed back up

|

| |  |

| | #105 |

| Rock Crawler Join Date: May 2004 Location: DFW, Texas

Posts: 662

|

Ah, thanks for clearing that up Joat. I'm definitely glad I went with the Proxxon then. No buyer's remorse here. Obviously I'm new to band saws. Is there a certain type of coolant liquid you use? What type of shops should I look for locally that would stock that? |

| |  |

| | #106 | |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

| Quote:

| |

| |  |

| | #107 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

great joat. thanks. cant wait to get my proxxon.

|

| |  |

| | #108 |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

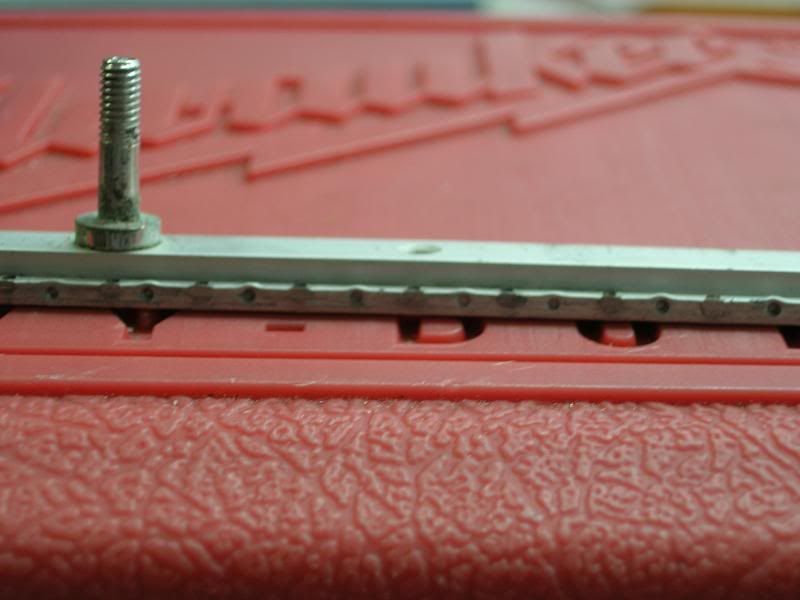

| Order the custom blades from probandsawworks.com 1/4 wide 14/18 bimetal, cheaper then buying the 10/14 from proxxon. When you get it you prob will notice alot of play on the slot for the miter gauge,heres the no cost only time fix for it.    Take a automatic center punch , I used a lisle red one here, but an adjustable will work just the same ,just dial back the power,and you want a more rounder tip then one that is pointy/sharp, the metal is pretty soft, so it wont take much force. First pic shows the dimples I made to widen the miter gauge slide bar thingy. on the bottom section on the sides, make dimples slightly offset from center to have the dimple protrude at the top of the bottom section,this will "pull" the miter gauge down futher into the slot and keep it from protruding above the table, next on the right side -futherest from the blade run a bunch of dimples on top of the bottom section, this will "push" the miter gauge closer to the blade and minimalize the side to side play for the miter gauge, be careful not to tear thru the metal -it is soft- also I did all the dimples in one set and went back and tweaked the some of them again, you will need to test fit to get the best fit,if your not running coolant then spray and very high quality silicone spray in the t slot and on the miter gauge, this will make it slide with little effort yet have very little free play, the true fix is to make a better slide out of brass, but it still will use dimples since the slot is not the greatest,but at least the brass will last alot longer Last edited by Joat; 04-02-2010 at 12:40 AM. |

| |  |

| | #109 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

awesome man. thanks for helping so much with this thread!

|

| |  |

| | #110 |

| Quarry Creeper  Join Date: Feb 2010 Location: Duluth

Posts: 388

|

Hey I forgot how well this works for a all around metal cutting band saw. Haven't used it to cut like this in years but just made a new table today (the one that came with was long gone to the garage gnomes) I've had this one for close to 20 years. Here's a link to a simlar one: bandsaw Buy the bimetal blades and you're set to go! |

| |  |

| | #111 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

good pic, but I primarily want a vertical one. wonder how old that one is.

|

| |  |

| | #112 | |

| Quarry Creeper  Join Date: Feb 2010 Location: Duluth

Posts: 388

| Quote:

I've used this one to build over 5000 feet of steel and alum dock, 20 or so tube bumpers and so many other projects its not even funny. As far as useing it verticly i have an old seat cushion that i set on the bed and i can sit down while useing it. | |

| |  |

| | #113 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

Dam. that thing is proven.

|

| |  |

| | #114 | |

| Rock Crawler Join Date: Apr 2008 Location: On the Snap on truck

Posts: 736

| Quote:

I still need to remake the table , my first one looked like yours pretty much, just a plate of metal, the next one I want to do will have a fence,get kinda lazy busting out the vise grips and bar stock, and I want a slot for a sliding miter gauge, the other mods in the works LOL, wet saw conversion and hydraulic down feed, the down feed I have the cylinder and valve, need to do the plumbing and attachments, the wet conversion, I have a nice rolling rubbermaid cart and the nozzles. | |

| |  |

| | #115 | |

| Quarry Creeper  Join Date: Feb 2010 Location: Duluth

Posts: 388

| Quote:

| |

| |  |

| | #116 |

| I wanna be Dave Join Date: Aug 2008 Location: Austin, TX, USA

Posts: 4,273

|

I finally got around to assembling the cheapy Harbor Freight 4x6 saw and so far I'm happy with it. Okay, it's your run of the mill low end "quality is optional" type of product so there were issues with the assembly, but from a functional standpoint I'm pretty happy with it. I made my first part with it over the last night or two and I'm pleased with it. My biggest complaints are the recess in the work table around the blade. Small parts are a pain. The other complaint is that the blade is a little wide so cutting curves will be tough and certainly prematurely wear the blade. Lastly, it's a little on the short side so even at just 6' tall, I find my back bothering me a bit after some cutting. Not a big deal, though... I'll get around to making a new work table. Thumper, I really like yours. Plain and simple. I think I'll follow your lead. |

| |  |

| | #117 | |

| RCC Addict Join Date: Feb 2006 Location: Medford, Oregon

Posts: 1,261

| Quote:

| |

| |  |

| | #118 |

| Quarry Creeper  Join Date: Feb 2010 Location: Duluth

Posts: 388

|

Like i said before find an old cushion and sit on the bed, no sore back and great for long involved cuts.

|

| |  |

|

| |