| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

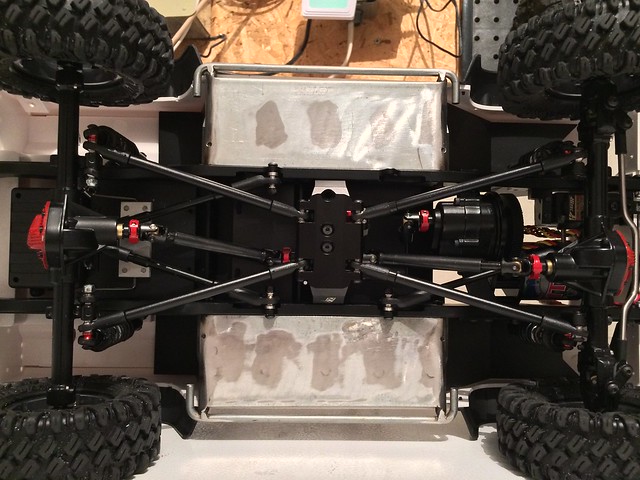

Day Zero – December 2, 2017: This is the start date for my winter 2017 build/project that I named “D90 Winch Challenge Pickup”. This project is 99% completed with many, many photos, therefore I will break it down to the major milestones that were achieved in order to lighten the read. I hope you enjoy! This build starts off with a decently sized order from Asia Tees which includes: a Boom Racing chassis, a Team Raffee D90 pickup hard body, a pre-made cage as a base to build on, Sandstorm KRAIT bead lock wheels, both 4.19” and 4.45” versions of the Boom Racing Hustler M/T 1.9” tires in the super sticky Snail Slime compound and lots of other goodies.  The inspiration for this build is this nice blue gem of a D90 pickup in the color “Pageant Blue” (Rover Group paint code 224 JNA) which was originally used by the British Motor Corporation starting in 1978 on Triumph cars.  D |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

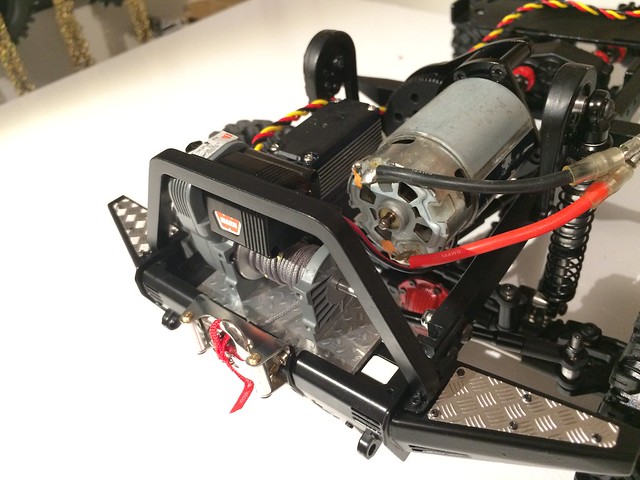

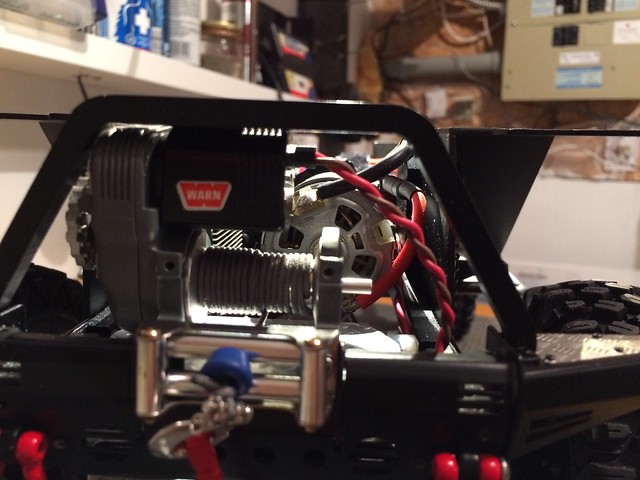

Update 2 – December 18, 2017: I started working on project D90 Winch Challenge Pickup; this super nice CChand front bumper was mounted and a complete chassis tear down was performed to shim and grease all the gears, Loctite all the standard screws, Shoe Goo’ed the drive shaft e-clips to prevent them from falling off during use and added steering limiters to protect the universals.     I had to fabricate a custom winch mounting plate for the RC4WD Warn 8274 winch I recently ordered as the CChand bumper is not designed to accommodate the 8274 winch, but is made for the smaller winches available in the RC4WD catalogue. A bit of scale realism was added to the design with an aluminum checkered plate that hides all the mounting screws for a clean look.      The clearance with the body is about 1 mm without the grill, which is just enough to remove/install it without any issues. The grill will be trimmed later to accommodate the winch just like they do on the 1:1 trucks.  D Last edited by valheru; 04-11-2018 at 02:57 PM. |

| |  |

| | #3 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

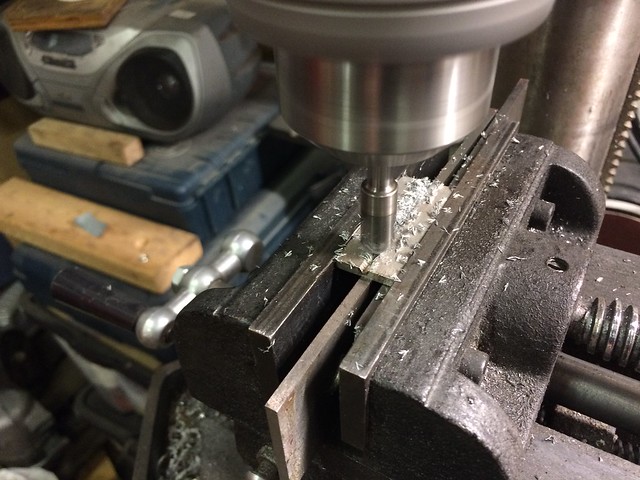

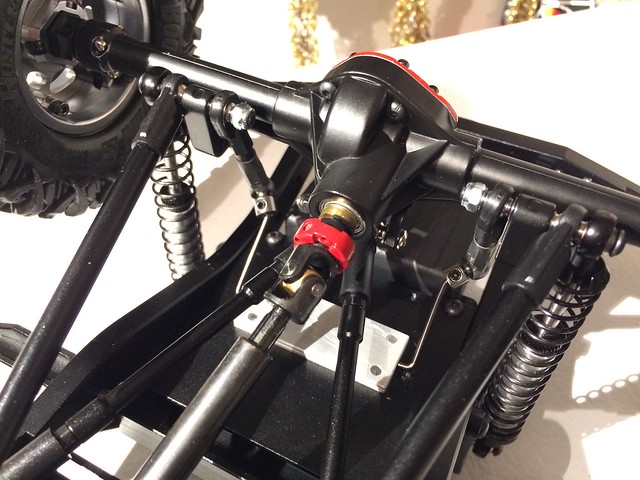

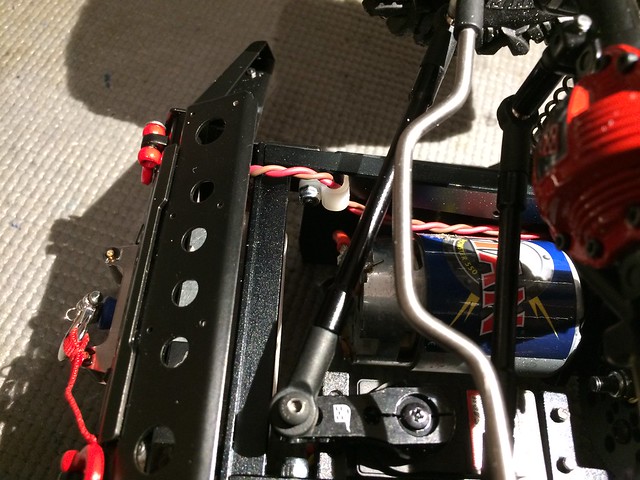

Update 3 – December 19, 2017: Next on my list, which is something I’ve added to almost every crawler/scaler I own, is a rear sway bar. The Boom Racing chassis has no reservation for one, therefore a full custom solution will be designed and fabricated using aluminium plate, a sway bar kit from Vaterra (VTR334001) for the basic components, custom adjustable links and mount the whole kit to the rear electronics tray.  It’s amazing what you can fabricate with a 3/4HP drill press, a ball bearing chuck, a cross vice and quality tooling.     With the smallest bar installed (for now), you can clearly see the difference it makes on the rear axle versus the front one (both axles have the same shock setup/ride height). Front:  Rear:  I also modified the rear bumper by mounting two shackles (see photo above), the final scale hardware being on order, and re-purposed a Traxxas blue silicone shock bump stop as a winch saver.   D :cool: |

| |  |

| | #4 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

Update 4 – December 23, 2017: You know, that gut wrenching feeling of no turning back on the first stroke of the saw on a brand new RC hard body... This morning, on the D90 Winch Challenge truck, I form fitted the grill to the monster RC4WD Warn 8274 winch.   I tried to keep the clearances as small as possible for that “it’s not going to fit“ look. Nothing is glued yet, just dry fitted, I am pretty satisfied with the end result.  D |

| |  |

| | #5 |

| Rock Crawler  Join Date: Dec 2014 Location: Union Bridge, MD

Posts: 502

|

I do know the feeling well. I just cut a Radio Shack Mangler Bronco in order to move the wheel well back. It was my first attempt at real body work so I was nervous. They don't make those bodies anymore. I also had to modify the grill on my f-350 to accommodate the same winch. I ended up putting a wire mesh from a pencil holder over the grill after I shaved it back. It actually looked better IMO.

|

| |  |

| | #6 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

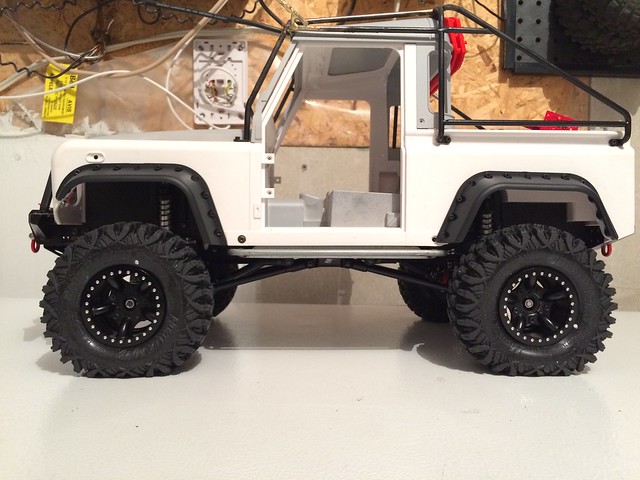

Update 5 – December 28, 2017 The fender flares were fitted and installed, the front corners of the body were cut to blend the fender flares better and give a better approach angle, and I started the planning for the install of the snorkel and the cage modifications I want to implement to protect both the snorkel and the body during roll-overs.    Today my new wheels arrived, they are RC4WD 1.9” Land Rover Defender Spectre edition (all black) and I mounted the Boom Racing Hustler M/T 1.9” x 4.45” tires on them.  And surprise, the shorter shocks I had on order also came in, I wanted to reduce the wheel gap and therefore I got me some 80mm GMade RSD emulsion type shocks, the stock shocks being 90mm Boom Racing shocks.  D |

| |  |

| | #7 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

Update 6 – December 29, 2017: Execution of the sun roof delete was started; first I made a styrene filler, than applied glazing putty.   In between the layers of glazing putty and sanding, I tinkered with the interior layout; I first removed the center console and patched the hole with styrene, then made a block-off plate to finish.   I then proceeded to delete the center console and fit a checkered plate to have a nice spot to mount a NOS tank, well within reach of the driver.   P.S. The driver of that truck has more issues than just keeping the inside of his vehicle clean! D |

| |  |

| | #8 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

| |

| |  |

| | #9 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

Update 8 – January 7, 2018: Spent a good part of the day working on project D90 winch challenge truck; this morning I did some weathering on the jerry cans and wear on the shovel.  I also fabricated front inner fenders.     Also, I painted most of the flat black components, including assembling the headlamps.  D |

| |  |

| | #10 |

| Newbie Join Date: Mar 2018 Location: Yukon

Posts: 19

|

Newb question. What is the purpose of adding sway bars to limit the rear suspension?

|

| |  |

| | #11 |

| Newbie Join Date: Mar 2018 Location: Yukon

Posts: 19

|

Cool build by the way!

|

| |  |

| | #12 |

| Quarry Creeper Join Date: Dec 2015 Location: NY

Posts: 211

|

Nice build so far... i love that bumper but its just too expensive for me! I also have the RSDs for my D90 project but the springs seem really stiff right? |

| |  |

| | #13 | ||

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

| Quote:

Works beautifully on my Wraith and my Slickrock and the minimal loss of articulation is outweighed by the benefits. Quote:

D | ||

| |  |

| | #14 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

Update 9 – January 10, 2018: I started modifying the cage I purchased for project D90 Winch Challenge pickup. I added an “X” brace to the roof section to add a bit more protection during roll-overs. Also in the mix was a loop around the snorkel to prevent it being ripped off when she goes shiny side down.    D |

| |  |

| | #15 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

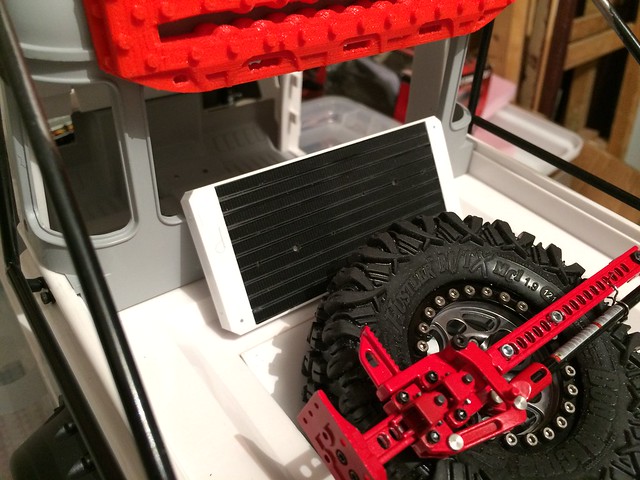

Update 10 – January 11, 2018: I wasn’t happy with the look and gaps in the protection that the X brace offered to the roof, therefore I replaced it with straight bars.  In the process of brazing the new roof section, I added mounting pins to store a pair of sand ladders. Simple and effective storage solution.  Also, I made a fake floor panel out of styrene to mount the spare tire and high-lift jack. The panel is held in place with rare earth magnets and will be covered post painting with a scale aluminum checkered plate.    D |

| |  |

| | #16 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

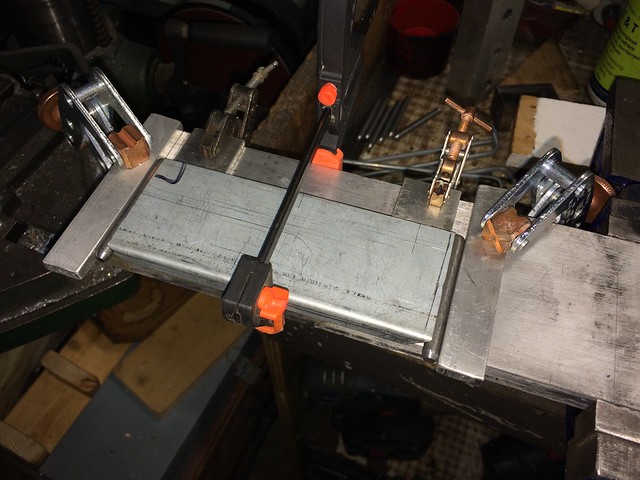

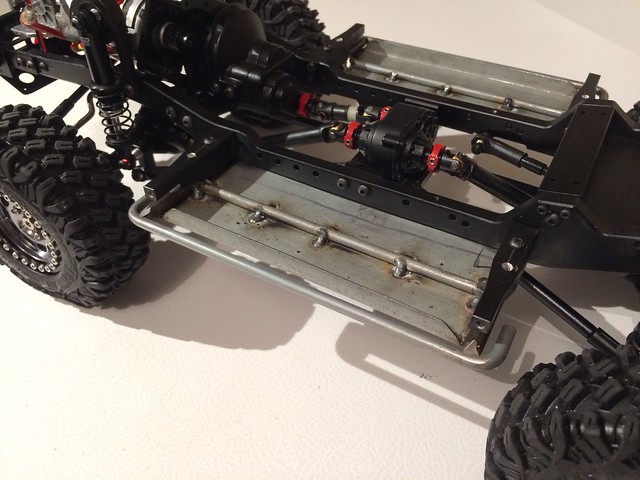

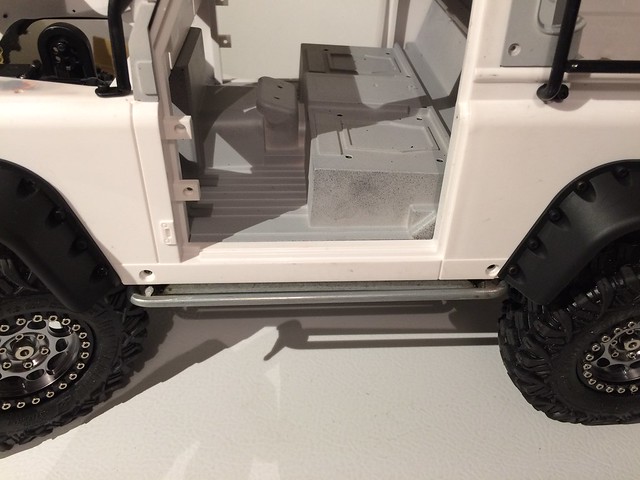

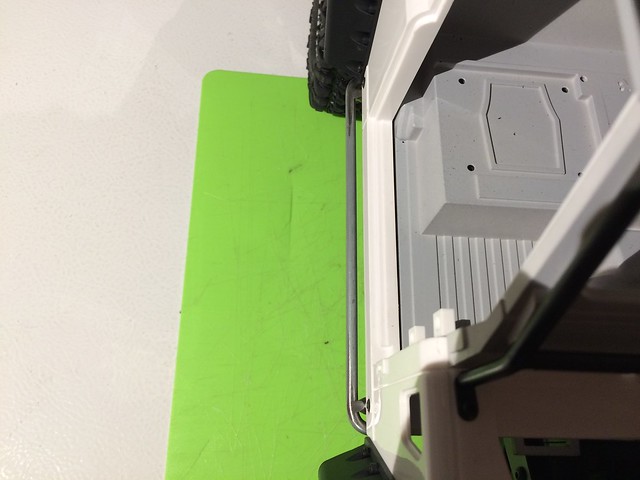

Update 11 – January 18, 2018: I am fabricating rock sliders/under armor for project D90 Winch Challenge Pickup, a total of 2 sets will be made, one for myself and the other for a good friend that bought at the same time as me a D90 chassis from Boom Racing. The short rods are 1/4” steel and will mount the sliders to the existing crossers that hold the body to the chassis and the long rods are 5/32” steel that are bent using a K&S Mighty Wire Bender, and will be the actual sliders.   The “armor” consist of automotive body repair sheet metal with a small section bent to form a “L” for stiffness.  After prepping the material (cutting, bending, etc.), I made temporary welding jigs to accelerate the process and have consistent results between the 4 sliders. I decided to MIG weld instead of brazing as the heat is almost instantaneous and very localized, which will not spread into the sheet metal/assembly, thus potentially deforming it like brazing will. Jig #1 is to weld the 1/4” mounting rods to the sheet metal.   Jig #2 is to weld a reinforcement bar that spans the entire length of the under armor, this should prevent the skid from collapsing under impacts.   Jig #3 is to attach the outer side/step bar.   I rounded of the leading and trailing edges of the under armour, did a rough cleanup of the welds (further cleanup to be executed prior painting), drilled and threaded some M3 for the mounting. The little lip sits about 0.5mm inside the body for a tight, clean look, and the side bars protrudes 6mm from the body.     D |

| |  |

| | #17 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

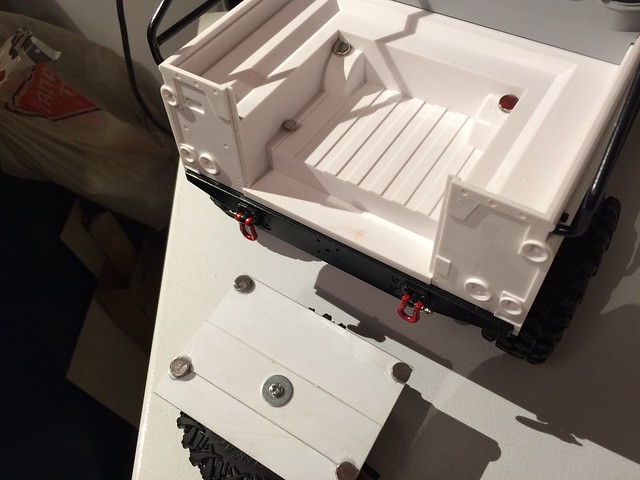

Update 12 – January 21, 2018: To complete the coverage of the chassis of the D90, I made some rear inner fenders out of .090” styrene and painted them flat black just like the front ones. Now, with both front and rear inner fenders, combined with the rock slider/under armour, I have pretty good coverage to keep the internals clean when out on the trails.    D Last edited by valheru; 04-30-2018 at 06:21 PM. |

| |  |

| | #18 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

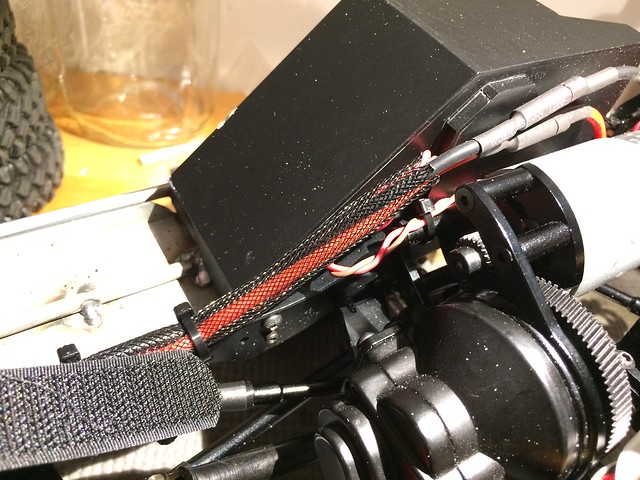

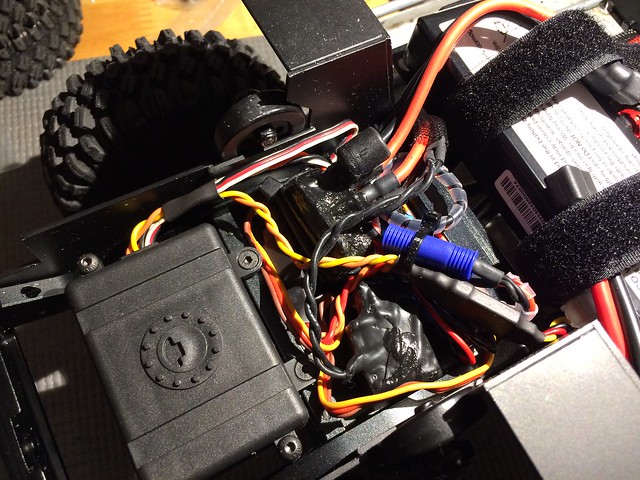

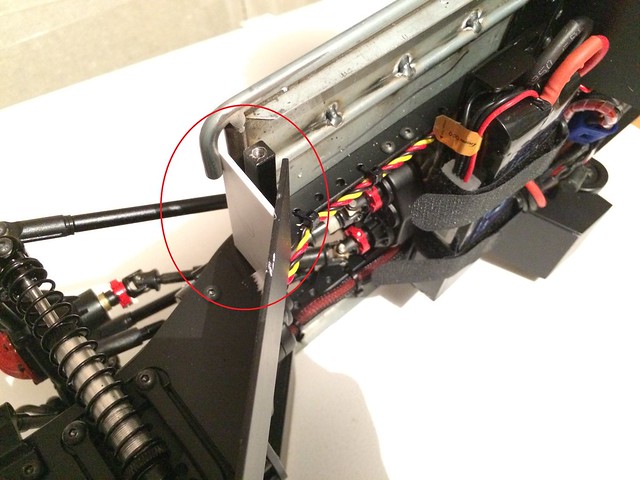

Update 13 – January 24, 2018: Good progress on project D90 Winch Challenge Pickup; I installed all the electronics including custom harnesses everywhere since some of the components were previously used in my Wraith. All the components were waterproofed using silicone conformal coating on the printed circuit boards and liquid electrical tape or Plasti Dip on the housings. The winch was hardwired to a HeyOk high voltage winch controller, which is programmed into Aux1 of the transmitter, therefore no separate remotes required to operate, and the controller has switchable dual power input: either thru the BEC (7.2V) or direct to the battery for the full 3S when more oomph is required. Steering duty is taken care of by a Hitec HS-7954SH servo directly which is powered by a Castle Creation 10A BEC set at 7.2V, motor control is thru a Tekin FXR ESC and the battery plugs were swapped to Dean connectors. This ended up being a fairly clean install with the only visible wires being a portion of the winch harness were it loops around the edge of the body before joining the rest of the motor wires which only a small portion of it didn’t fit under the floor of the interior, therefore I had to run it parallel to the inside of the frame rail for a bit.       Now, I just need to figure out what brushed motor to run on 3S LiPo; so far I tried the Traxxas 550 can 21T, 540 can 45T and 55T. Love the torque of the 21T, but way too fast for the D90, and the 55T has the proper speed, but half the torque of the 21T... I might give a call to Holmes Hobbies for a recommendation. I re-installed the stock 90mm shocks since I was having rubbing issues on the body with the 4.45” tires. Still has plenty of flex, but will need to find some 3-4mm wide hexes to bring the tires back under the flares. The 80mm Gmade RSD shocks are awesome, but better sized for 4 to 4.25” tires, nothing bigger.        Next on the list to complete the electronics will be the light kit once the 3mm LED kit I ordered arrive. D |

| |  |

| | #19 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

Update 14 – January 25, 2018: Next on my to-do list is the relocation of the radiator to the cargo box since the 8274 winch sits in the location of the stock radiator. For this I ordered the EXO Rear Light Bezel and Radiator Set (AX80103) from Axial and from Shapeways 2 different designs of oil coolers.    D |

| |  |

| | #20 |

| Quarry Creeper  Join Date: Apr 2016 Location: Canada, Ottawa/Gatineau

Posts: 290

|

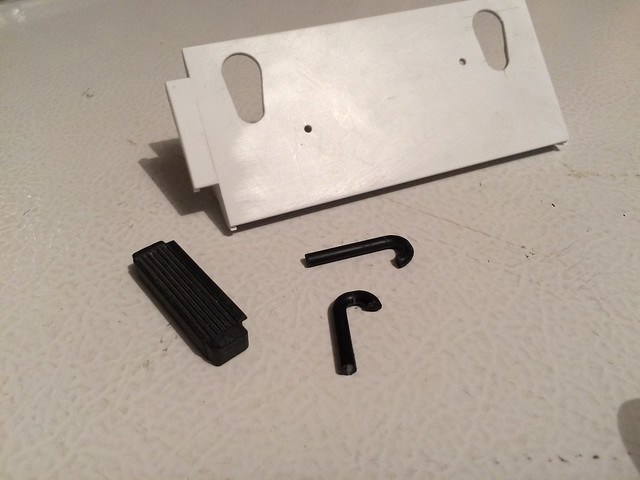

Update 15 – January 28, 2018: I wasn’t happy with the scale of the 1:10 Axial radiator in relation to the scale of the Team Raffee D90 body which is closer to 1:8.82 (when calculated against the dimensions of an actual D90). Therefore I scratch built a radiator out of styrene and tie-wraps and made it 20% bigger than the 1/10 Axial one which is still of use as I will be reusing the fans from the Axial kit, but will add a shroud to the radiator like a real one would have.     As part of the radiator relocation, I made a radiator mounting bracket which will be fixed directly to the cargo box with all the hardware hidden, which includes a tab to mount an external oil cooler.   Both the oil cooler and the radiator will be fitted with rigid piping; the cooler one is made with the corners of scree of a plastic model kit and the radiator piping will be made out if either 1/4” steel rod or brake line or styrene rod.     While I was in styrene work, I added a small section to the front inner fenders to prevent infiltration of mud and debris at the junction between the inner fender and the body mounts/under armour.  D :cool: |

| |  |

|

D90 Winch Challenge Pickup - Similar Threads

D90 Winch Challenge Pickup - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| From D90 to D110 pickup | Binnendoor | 1.9 Scale Rigs | 10 | 09-27-2017 01:44 PM |

| D90 pickup | J55TTC | 1.9 Scale Rigs | 51 | 09-02-2017 01:05 PM |

| 1.7 D90 pickup | THEmicroRR | 1.5 Scale Rigs | 10 | 03-25-2014 11:00 PM |

| |