| | #21 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

| |

| |  |

| Sponsored Links | |

| | #22 |

| Rock Crawler Join Date: May 2009 Location: Medford, Oregon

Posts: 692

| Last edited by RIG_RIDER; 02-08-2011 at 07:54 PM. |

| |  |

| | #23 | |||

| Rock Crawler Join Date: Aug 2007 Location: mesa az

Posts: 657

| Quote:

Quote:

Quote:

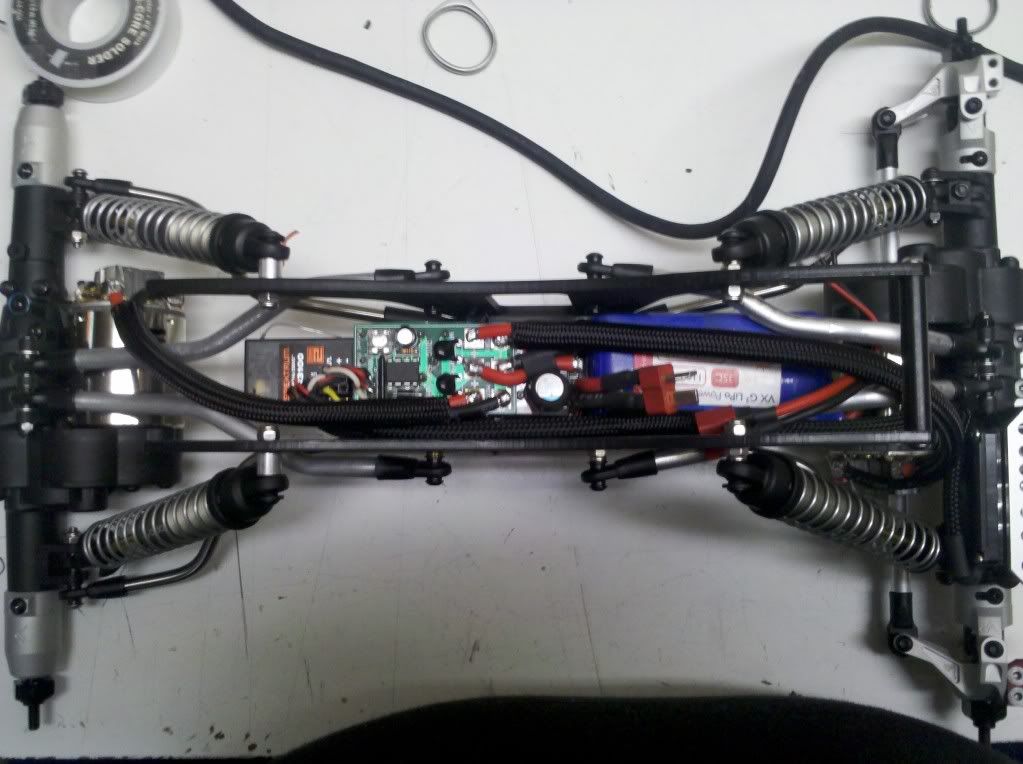

I pride myself on using no zip ties. Here is a pic of mine same setup as briansbodies  | |||

| |  |

| | #24 |

| Try to Bend it  Join Date: Aug 2009 Location: Perth Australia

Posts: 3,163

|

Very nice smokey, I like your work.

|

| |  |

| | #25 |

| Pebble Pounder Join Date: Nov 2007 Location: Alice Springs/Australia

Posts: 131

|

This is my setup take it easy Im an electrician so you know how that goes

|

| |  |

| | #26 |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

|

Thanks Helhedded  I used to sleeve everything like smokey does, but it got to be a pain in a comp truck where you always need to work on something. Now in a scaler, it's the only clean way to do it. I've seen the sleeving down to 1/8" diameters, it's great for cleaning up the rats nest that our scalers usually are. |

| |  |

| | #27 |

| Quarry Creeper Join Date: Nov 2009 Location: East Greenville

Posts: 226

|

whats the normal size for this sleeving you guys are using

|

| |  |

| | #28 |

| I wanna be Dave  Join Date: Feb 2005 Location: Burnsville

Posts: 3,096

|

Sleeve can be found at McMaster-Carr in various designs and colors.... http://www.mcmaster.com/#sleeving/=atgo04 I just picked up some that is wrap-around and secures with velcro. Makes it easy to remove when stuff needs to come out. |

| |  |

| | #29 | |

| Rock Crawler Join Date: Jun 2010 Location: Yelm,WA

Posts: 695

| Quote:

http://www.frys.com/product/2281388;...H:MAIN_RSLT_PG $6.99 for 16FT ID= 1/4" Min. Diameter= 5/32" Max Diameter= 7/16" I was going to get 1/8" but it looked way to small & I didnt want it to be a super tight fit. | |

| |  |

| | #30 | |

| Rock Crawler Join Date: Aug 2007 Location: mesa az

Posts: 657

| Quote:

| |

| |  |

| | #31 |

| RCC Addict Join Date: Aug 2009 Location: Earth?

Posts: 1,698

|

Looks nice, adds weight.

|

| |  |

| | #32 |

| Rock Crawler Join Date: Jun 2010 Location: Yelm,WA

Posts: 695

| Maybe I'll stop and pick some 1/8" up sometime to give it a shot, I just didnt want to make an hour drive for something that wasn't going to work so I got the next size up.

|

| |  |

| | #33 |

| Rock Crawler Join Date: Aug 2007 Location: mesa az

Posts: 657

| |

| |  |

| | #34 |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

| |

| |  |

| | #35 |

| Rock Crawler Join Date: Aug 2007 Location: mesa az

Posts: 657

| |

| |  |

| | #36 |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

| 20 my friend A long time ago my friend eric113 rewired from large wire and big Deans to smaller wire and micro deans. His wiring was a bit excessive in the beginning, but he managed to remove about 3 oz. DNA Slingshot |

| |  |

| | #37 | ||

| Quarry Creeper Join Date: Jan 2011 Location: Michigan

Posts: 237

| Quote:

Quote:

whoodie, Not to pretend that I am any type of electronics guru, nor am I here to incite argument or anything of that sort. That said, I do have a question/comment of sorts. I had always been of the understanding that smaller gauge wire, from batteries or to motors was a current bottle neck. I had also heard that the smaller gauge would not only heat up excessively, it would also rob the motor or electric system from drawing the amp/volts it needed to run at full potential. The smaller gauge was always relegated to smaller scale and less power applications, where as larger dia. was the norm for the 1/10 scale and up duties. If any of this is true, then it seems like a very high price to pay for a 3oz. weight savings. Of course, if it is all just wives tales then why in the heck are so many of us wasting money on expensive large gauge noodle wire and full size Deans connectors! | ||

| |  |

| | #38 | |

| Moderator  Join Date: Jul 2007 Location: Texas baby!

Posts: 1,498

|

I'm so glad you asked me to back up my reasoning for using small wire and connectors  Your understanding of small wire being a bottleneck is absolutely correct. Wire that is too small will not allow you to pass the current needed, it will heat up, and eventually fail. But how small is too small? Before I made the switch to smaller wire and connectors I did a current study. After running a 5 minute course, I logged the amount of capacity that I used. It was really easy using my charger, as it has the info right on the screen. With 2 30T motors I use on average 120 mAh in 5 minutes. Let's say this is a really tough course and I used 200mAh in 5 minutes. Doing a little math. 200 mAh = .2 Ah = 12 Am (Amp minutes) Divide that by how long you ran, in my case 5 minutes. 12 Am/5m= 2.4 Amps 2.4 Amps! That is the average current draw for my application Now you tell me if you need wire that is rated for 100's of amps  Quote:

| |

| |  |

| | #39 | |

| Quarry Creeper Join Date: Jan 2011 Location: Michigan

Posts: 237

|

Well thank you so much for sharing this mini study of yours! I have always erred on the side of (let those that know more than me guide me) so the old school way of thinking I shared with you, was what I was taught years ago and some of it I'm sure carried over from my Car stereo/amplifier installation days. But good information is contagious and I believe you may have just added a convert to your ranks whoodie! Now if we could convince my wife that "smaller is better"  Quote:

| |

| |  |

| | #40 |

| Pebble Pounder Join Date: Jun 2010 Location: everett

Posts: 156

| |

| |  |

|

| |