| | #61 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

Awesome!!!!!

|

| |  |

| Sponsored Links | |

| | #62 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

upon Juans instruction. flipped the skid plate so the fly wheel was facing the hood/front axle. still having clearance issues. Edit: it's the stock sealed end bell like MRC said it was. He's right, the skid is drilled perfectly.        Last edited by Crawford; 08-11-2011 at 10:48 PM. |

| |  |

| | #63 |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

|

you can do it Crawford...I've been secretly lurking in here watching this thread.... what are you using to shoot the pictures...nice clean close-ups  |

| |  |

| | #64 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

im guessing because your running the stock caned-endbell motor, because modify-able motors have move clearance.. will post pics of the difference.

|

| |  |

| | #65 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

This is your standard canned endbell motor  This is a modified motor: (the one in my crawler is a bit shorter than the ^standard canned endbell, but this motor is longer than standard, but you get the idea...)  |

| |  |

| | #66 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Haven't pulled out the bigger camera yet. Mrc, Hopefully I'll figure out a way to run this 27t.... I don't really want to spend 50 bucks on a new motor then another 50-60 on MIP's. Thanks for the lengths bro | |

| |  |

| | #67 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

Actually.. you may be able to get through spacing the center housing up from the skid plate.. although your COG will be altered even by 2-3mm height.. how much are you wiling to spend? i may go help you find a motor cheap  | |

| |  |

| | #68 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

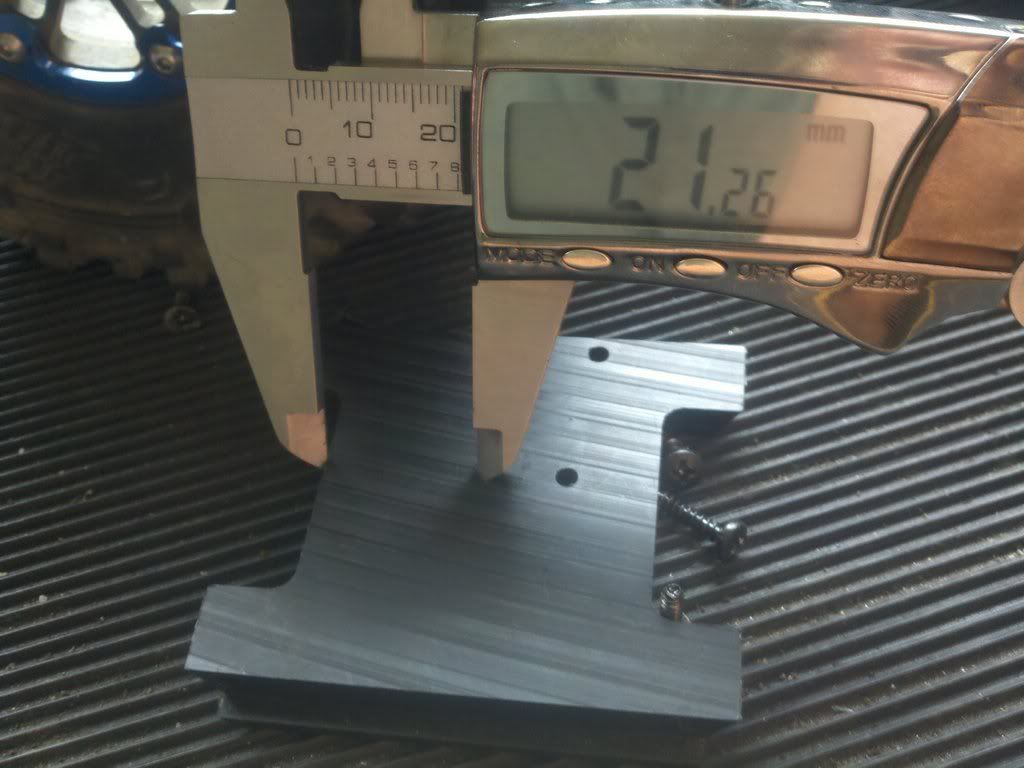

motor & plate run 2.02 inches.. doesn't seem excessively long...

|

| |  |

| | #69 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

If I were to get another motor I'd buy the good stuff the first time. probably an HH 35turn so I can run a steel pinion and have a little more power & low end crawlability... | |

| |  |

| | #70 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| ah i see. I was thinking a Tekin motor. they had motors for like $10-20 awhile back on rpphobby.

|

| |  |

| | #71 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| |

| |  |

| | #72 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

Any brand overall is good.. JUST not integy or Venom. but id say, for a low price, Tekin is one of the best. But you can get a HH 35T for 28.99 now, which is about the price of any other motor on the market.    unless your looking at the comp spec ones from HH. unless your looking at the comp spec ones from HH.http://holmeshobbies.com/product.php...&cat=17&page=1 Personally, i believe all motors are the same, in terms of how they run, low ends, high ends, but in the end, its life, and durability seem to be a big deal. What seperates the motors are Handwound VS Machinewound. Machinewound i believe is good enough for weekend crawling and little comping.. Handwound is good for comping, and too good for just weekend crawling IMO. Right now im running a weird setup on my XR, Handwound on front, Machinewound on rear. Both have same power output, high-end.. But the difference is big in the Low end and Smooth start department. | |

| |  |

| | #73 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

but i must admit.. I ran RC4wd canned endbell motors for along time on my XR-10, and they are 10 EA! I got through 2 comps with them, and with them i got a pretty good place for a 1st timer. They were very good to me, and i still run them, however, i gave one to Brownie, since his rear motor died out. |

| |  |

| | #74 |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

|

What's wrong with the Integy's ??? I got mine for $19 ...if you take care of them they should last...I'm just a weekend warior though. They've been good to me....watch, now that I said something they'll die |

| |  |

| | #75 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

The integy drivers worked fine up until today when I looked at my 2.5mm driver a little funny, it got mad and the shaft started to spin inside the handle. I'm looking around, not sure what turn I want... may try just volting up a little bit. Post, what motor are you running? I know it wont correlate to mine since the gearing i'm sure is way different but I thought I'd ask. | |

| |  |

| | #76 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

Well, actually.. going back to the thread.. seems like its okay, but this is what i read of the most bad comment on them from another user. Integy Pro Lathe motors any good? Last edited by MRCCRAWLER1.9; 08-09-2011 at 12:06 AM. | |

| |  |

| | #77 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

| |

| |  |

| | #78 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Seems like a 35t would fit the bill maybe with a 20t pinion.... we'll see. I think in the mean time I'll try shimming the trans/motor up a little to get it to fit in nice for the weekend. Last edited by Crawford; 08-09-2011 at 12:10 AM. | |

| |  |

| | #79 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

hmm, weird, i just saw another fast back, and it looked like he didnt have an issue.. but pics werent the best. Is your tranny not fitting? or is it just touching even when mounted fully? | |

| |  |

| | #80 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

| |

| |  |

|

| |